Oil filter nut disassembling and assembling wrench

An oil filter and nut technology, used in wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of uncontrollable locking force, increased maintenance time, loosening of tightening nuts, etc., and achieves stable and reliable assembly quality and labor intensity. The effect of reducing and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

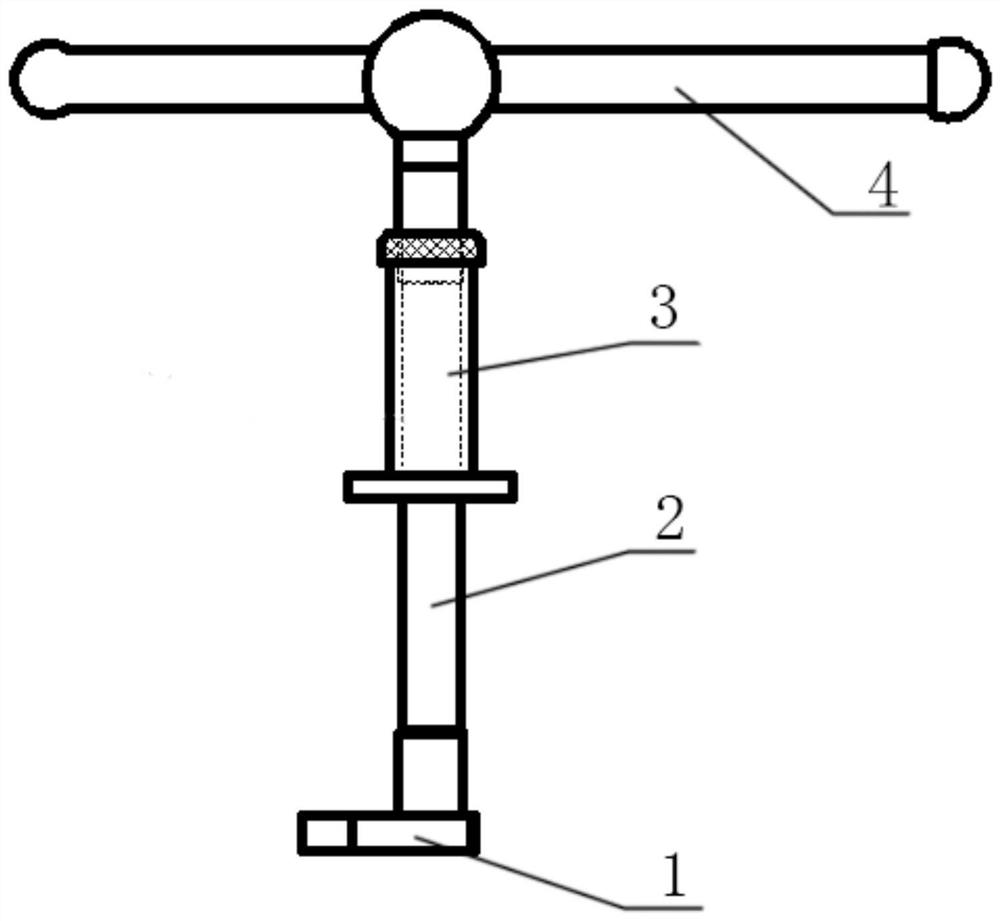

[0027] Such as Figure 1-7 As shown, a wrench for dismounting and assembling an oil filter nut includes an arc-shaped claw 1, a torque rod 2, a locking thread sleeve 3, and a wrench rod 4. One end of the torque rod 2 is connected to the arc-shaped claw 1, and the other end It is connected with the wrench rod, and the middle thread is connected with a locking threaded sleeve 3.

[0028] The working principle of the present invention is: the present invention utilizes the length dimension of the torsion bar 2 to avoid obstacles, and transmits the force of the wrench bar 4 to the torsion bar 2, so that the torsion bar 2 generates torsional force, that is, the force applied from a high place The thrust is transmitted as low torque, so that the oil filter nut 6 can be easily disassembled or installed, and the working environment has been greatly improved; among them: the locking threaded sleeve 3 is placed first figure 1 position, hold the spherical end 23 of the torsion bar 2, in...

Embodiment 2

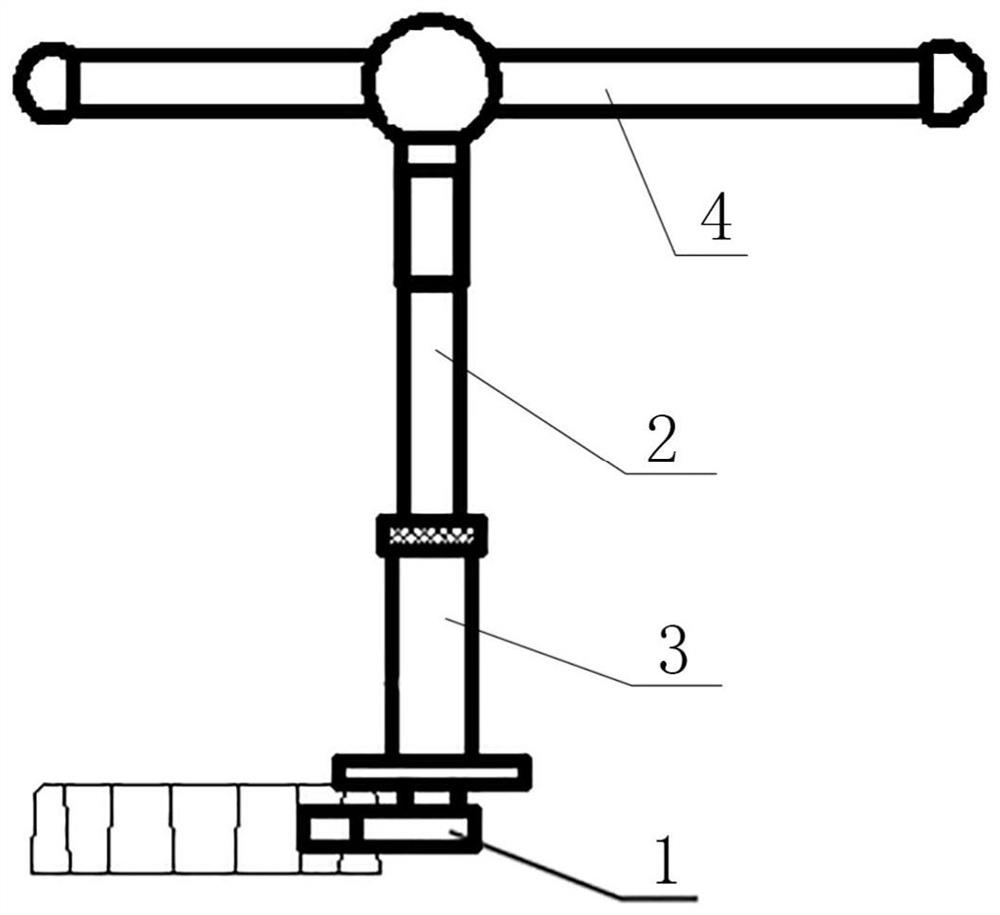

[0031] On the basis of Embodiment 1, the upper and lower parts of the torsion bar 2 are respectively provided with a suspension external thread 22 and a locking external thread 21, and the end close to the suspension external thread 22 is provided with a spherical end 23, and the inside of the spherical end 23 is horizontal. There is a through hole 24, the wrench rod passes through the through hole 24 and is connected with the torsion bar 2, the hanging external thread 22 at the upper end can hang the locking thread sleeve 3; the locking external thread 21 at the lower end is used to lock the oil filter nut 6. The cylinder at the lower end fits with the fixing hole 11 in the arc claw 1 and is welded firmly; the wrench uses the length of the torsion bar 2 to avoid obstacles, and when the torsion bar 2 bears the torsion, the oil filter nut 6 can be rotated Tighten or loosen.

Embodiment 3

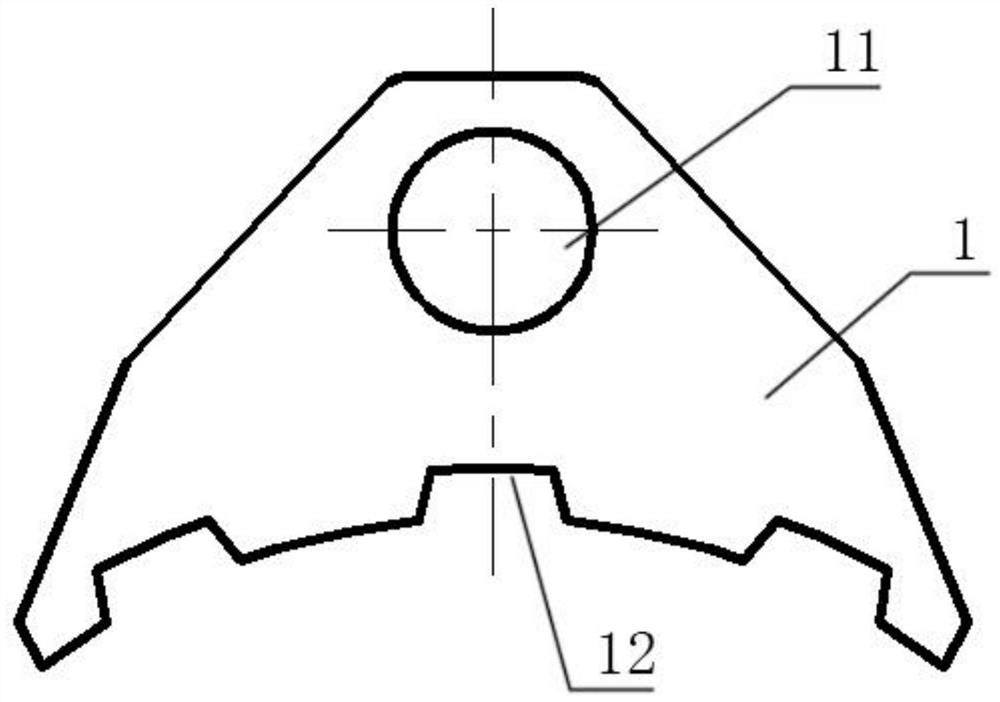

[0033] On the basis of Embodiment 2, the arc-shaped claw 1 is provided with a fixing hole 11, which is connected to the torsion bar 2, and the inner side of the arc-shaped claw 1 is equidistantly provided with claw teeth 12. The inclination of claw tooth part 12 is set to ∠3°, the arc-shaped claw 1 has good rigidity and large contact area, and the claw tooth part 12 is designed to be a 3° slope, which corresponds to the slope of the oil filter nut 6 tooth slots. It is beneficial to make the teeth contact tightly, reduce the contact gap, and facilitate the arc-shaped claw 1 not to slip out of the tooth groove of the oil filter nut 6 when torque is applied.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com