Self-adaptive defect identification method for train wheel tread taper hole detection

A technology for identifying train wheels and defects, which is applied in the field of image processing and can solve problems such as being easily affected by the shooting environment and conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] specific implementation plan

[0050] In order to make the object, technical solution and advantages of the present invention clearer, further detailed description will be given below in conjunction with the accompanying drawings.

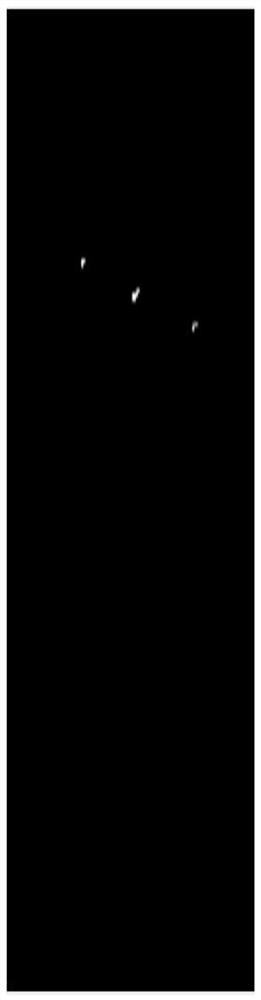

[0051] An adaptive defect recognition method for the detection of conical holes in train wheel treads, such as Figure 4 shown, including the following steps:

[0052] 1) Obtain the image to be processed, convert its pixel value matrix from RGB color space to Lab color space, and separate three color channels;

[0053] The formula for converting the image pixel value matrix from the RGB color space to the Lab color space is as follows:

[0054]

[0055]

[0056]

[0057]

[0058]

[0059] Among them, X n =95.047, Y n =100, Z n =108.883; In the Lab color space, a * , b * stands for color, L * Represents light intensity.

[0060] 2) Set the sliding protection window and the sliding detection window, calculate the expectat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com