Pile construction method and special equipment

A construction method and equipment technology, applied in sheet pile walls, infrastructure engineering, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

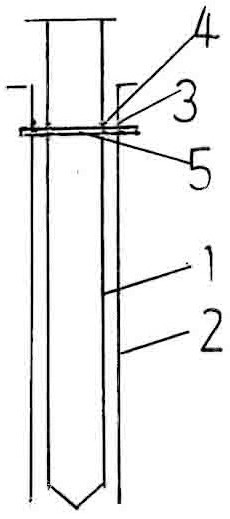

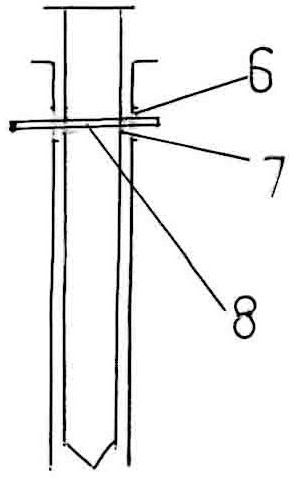

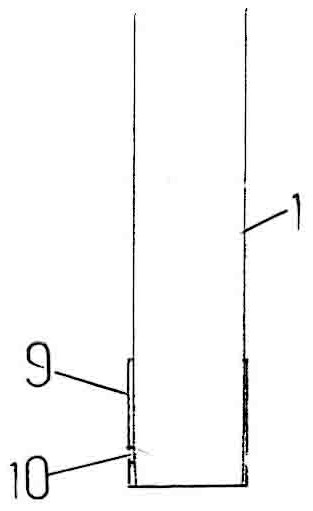

[0023] A method for constructing a pile, comprising the steps of equipment immersed pipe system in place, immersed pipe, material feeding, bottom expansion, pouring, and extubation. The steel shaft connection device is fixed; the length of the inner tube into the outer tube is not less than the length of the outer tube; the symmetrical sides of the outer tube and the inner tube are opened at the same time, and a steel shaft with a length greater than the diameter of the outer tube is used to pass through the hole for fixing; Or open large slot holes on the symmetrical sides of the outer tube, and open small slots on both sides of the inner tube, and use a steel shaft with a length greater than the diameter of the outer tube to move or fix relative to the large slot holes on both sides of the outer tube; the inner tube is hollow For the steel pipe, the upper part is provided with a ramming plate, the top is equipped with a hoisting device for the wire rope to be lifted, the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com