Electric power engineering rush-repair combined operation vehicle

A technology of joint operation and power engineering, applied in the directions of overhead line/cable equipment, lifting equipment safety device, hoisting device, etc., can solve the problems of rigid movement and adjustment of work ladders, low power repair efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

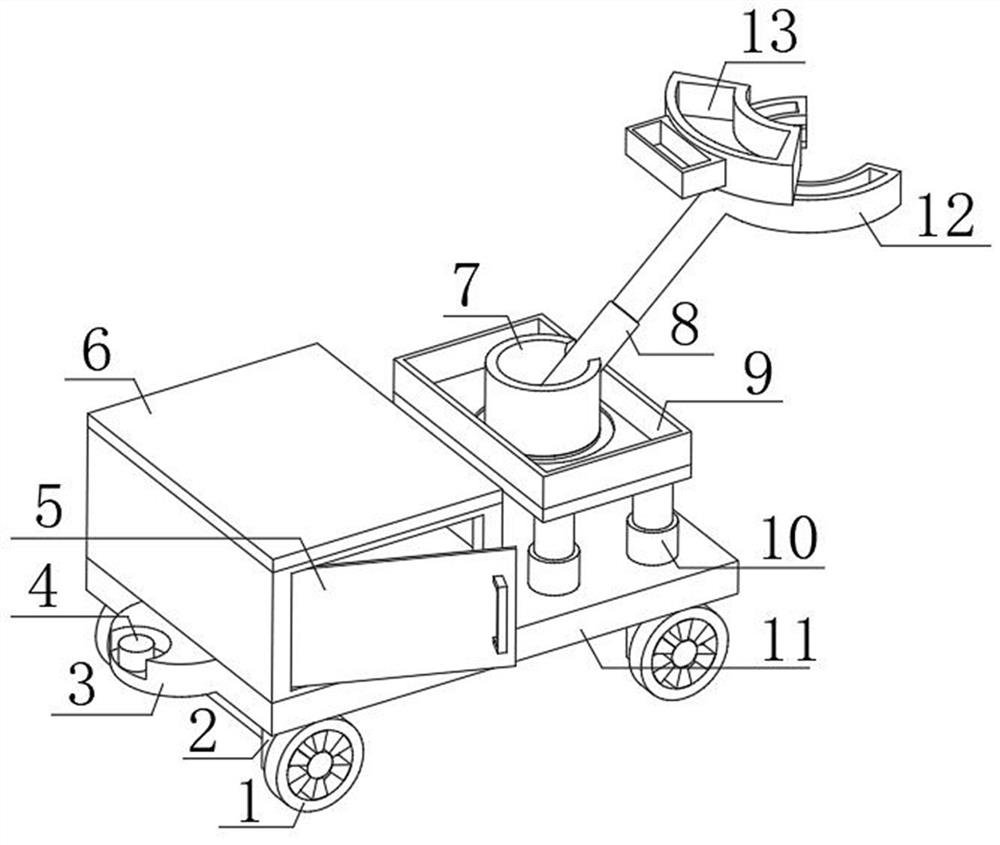

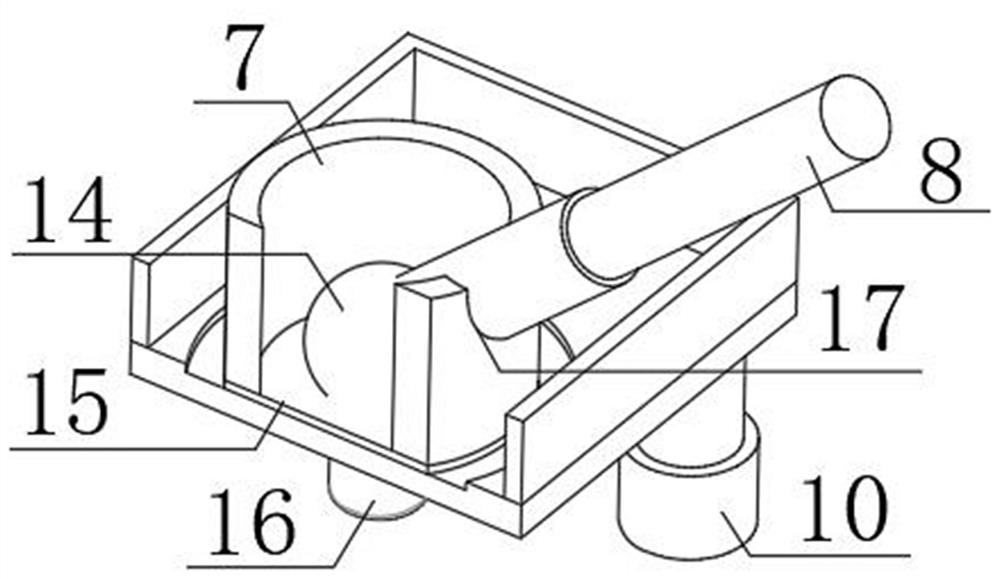

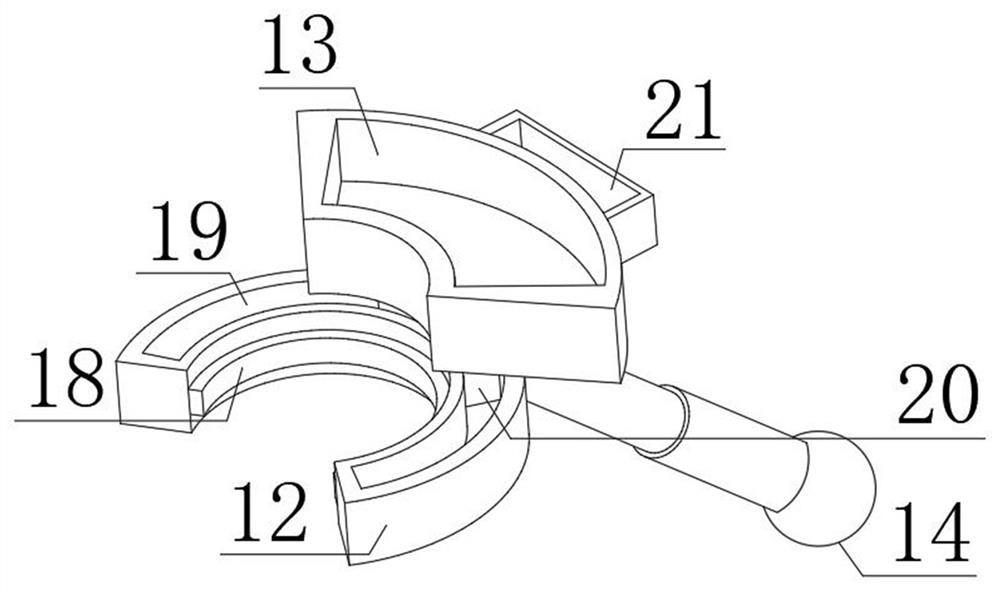

[0025] refer to Figure 1-4 , a combined operation vehicle for electric power engineering emergency repair, comprising a compartment floor 11, one side of the top outer wall of the compartment floor 11 is fixedly connected with four electric telescopic rods 10 distributed equidistantly, and one end of the extension rods of the four electric telescopic rods 10 is fixedly connected with Same fixed table 9, the central position of fixed table 9 top outer wall is provided with rotating disk 15, is fixedly connected with fixed frame 7 on the top outer wall of rotating disk 15, is provided with universal adjustment ball head 14 on the bottom inner wall of fixed frame 7, fixed frame 7 is provided with a limit groove 17 on one side of the outer wall, and a hydraulic rod 8 is fixedly connected to one side of the universal adjustment ball head 14. One end of the extension rod of the hydraulic rod 8 is fixedly connected to an adjustment frame 12, and the top outer wall of the adjustment f...

Embodiment 2

[0033] refer to Figure 5 , a combined operation vehicle for electric power engineering emergency repair, comprising a compartment floor 11, one side of the top outer wall of the compartment floor 11 is fixedly connected with four electric telescopic rods 10 distributed equidistantly, and one end of the extension rods of the four electric telescopic rods 10 is fixedly connected with Same fixed table 9, the central position of fixed table 9 top outer wall is provided with rotating disk 15, is fixedly connected with fixed frame 7 on the top outer wall of rotating disk 15, is provided with universal adjustment ball head 14 on the bottom inner wall of fixed frame 7, fixed frame 7 is provided with a limit groove 17 on one side of the outer wall, and a hydraulic rod 8 is fixedly connected to one side of the universal adjustment ball head 14. One end of the extension rod of the hydraulic rod 8 is fixedly connected to an adjustment frame 12, and the top outer wall of the adjustment fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com