Automobile carpet structure and arrangement mode

A technology for car carpets and cars, which is applied to vehicle parts, chemical instruments and methods, and special positions of vehicles, etc. It can solve the problems of carpet VOC not up to the standard, the overall weight of the carpet is large, and the installation is difficult for workers, so as to improve the structure of the carpet layer, Guarantees sound-absorbing and insulating properties and reduces the weight of the carpet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

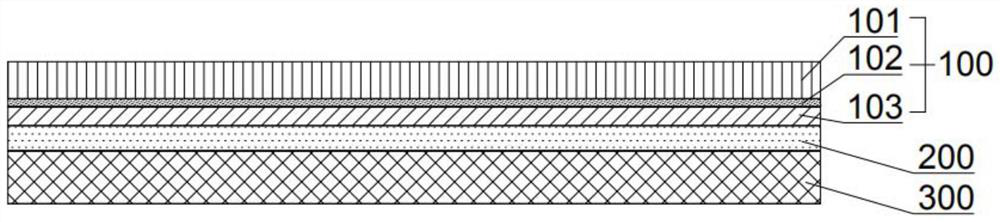

[0028] like figure 1 As shown, the present embodiment provides an automobile carpet structure, which includes a carpet surface layer 100 , a rubber film or rubber powder layer 200 and a felt layer 300 from top to bottom.

[0029] The carpet surface layer 100 includes a skin layer 101, a film-attached layer 102 and a base layer 103, the skin layer 101 includes 85% PET and 15% LPET, and the areal density is 200-450 g / m 2 ; The film-attached layer 102 includes a PE film with an areal density of 70 to 120 g / m 2 ; The base layer 103 includes 85% PET and 15% LPET, and the areal density is 300 to 600 g / m 2 ; The thickness of the blanket surface layer 100 is 3 to 6 mm.

[0030] The glue film or glue powder layer 200 includes PE film or glue powder, and the surface density is 70-120g / m 2 .

[0031] The felt layer 300 includes an equal density PET felt with an areal density of 600-2000 g / m 2 , the thickness is 3 ~ 25mm.

[0032] Considering that there are no stepping requirements ...

Embodiment 2

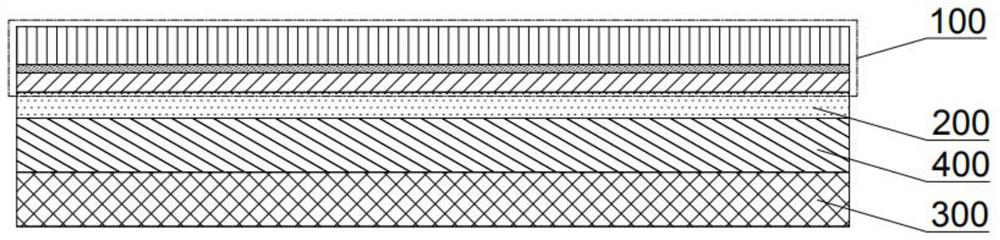

[0034] like figure 2 As shown, the present embodiment provides an automobile carpet structure, which includes a top-to-bottom carpet surface layer 100 , a rubber film or rubber powder layer 200 , a heavy layer 400 and a felt layer 300 .

[0035] The carpet surface layer 100 includes a skin layer 101, a film-attached layer 102 and a base layer 103, the skin layer 101 includes 85% PET and 15% LPET, and the areal density is 200-450 g / m 2 ; The film-attached layer 102 includes a PE film with an areal density of 70 to 120 g / m 2 ; The base layer 103 includes 85% PET and 15% LPET, and the areal density is 300 to 600 g / m 2 ; The thickness of the blanket surface layer 100 is 3 to 6 mm.

[0036] The glue film or glue powder layer 200 includes PE film or glue powder, and the surface density is 70-120g / m 2 .

[0037] The heavy layer 400 adopts 800~4000g / m 2 EPDM, the thickness is 1.5 ~ 4mm.

[0038] The felt layer 300 includes an equal density PET felt with an areal density of 600-...

Embodiment 3

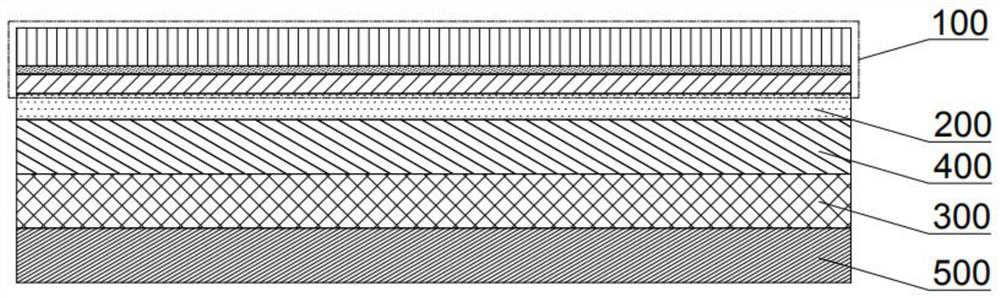

[0041] like image 3 As shown, the present embodiment provides an automobile carpet structure, which includes a carpet surface layer 100 , a rubber film or rubber powder layer 200 , a heavy layer 400 , a felt layer 300 and a sound absorbing layer 500 from top to bottom.

[0042] The carpet surface layer 100 includes a skin layer 101, a film-attached layer 102 and a base layer 103, the skin layer 101 includes 85% PET and 15% LPET, and the areal density is 200-450 g / m 2 ; The film-attached layer 102 includes a PE film with an areal density of 70 to 120 g / m 2 ; The base layer 103 includes 85% PET and 15% LPET, and the areal density is 300 to 600 g / m 2 ; The thickness of the blanket surface layer 100 is 3 to 6 mm.

[0043] The glue film or glue powder layer 200 includes PE film or glue powder, and the surface density is 70-120g / m 2 .

[0044] The heavy layer 400 adopts EPDM of 800-4000 g / m 2 and has a thickness of 1.5-4 mm.

[0045] The felt layer 300 includes an equal densit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com