Axially telescopic automatic tightening mechanism

An axial telescopic and automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low operating time utilization, low production efficiency, complex structure, etc., to improve consistency and stable reliability , Improve the assembly efficiency, the effect of small size of the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

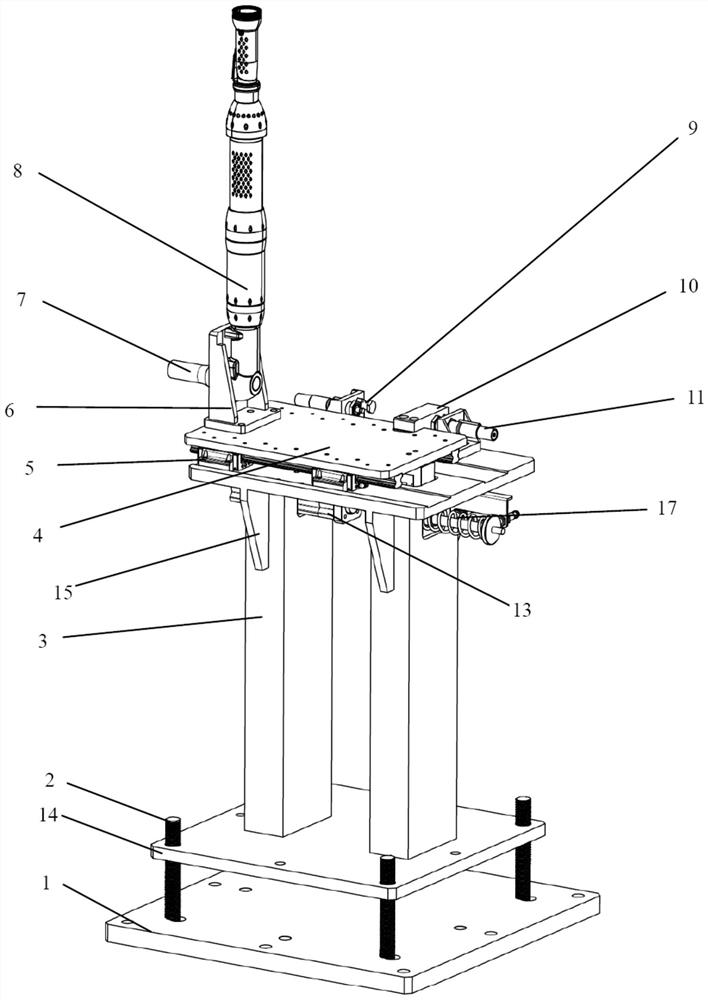

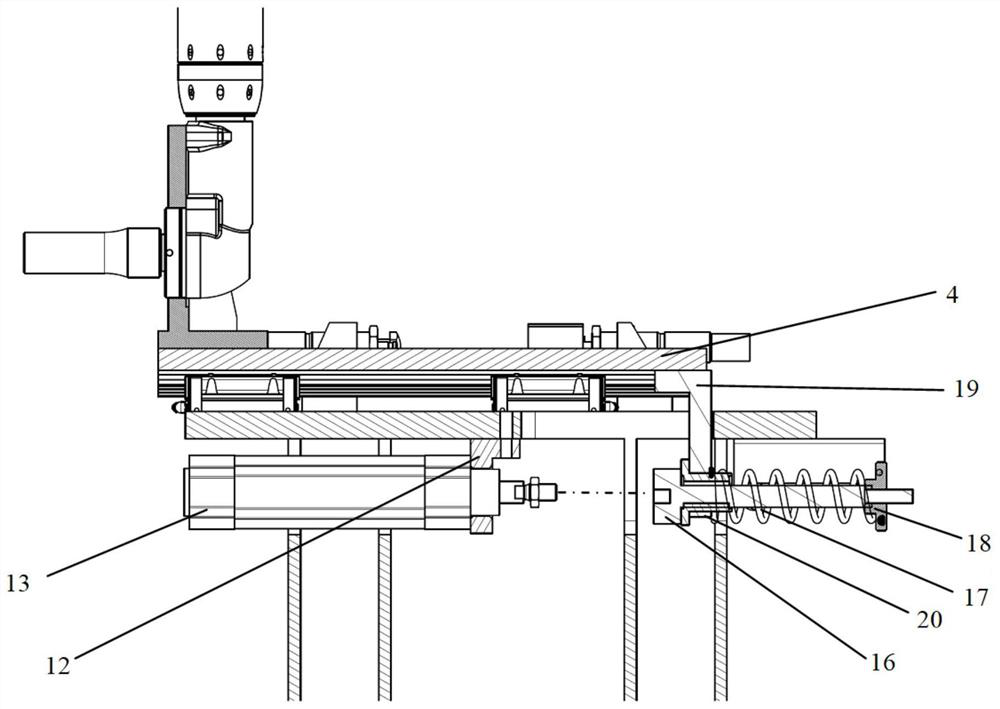

[0017] The preferred embodiments of the present invention will be further detailed in connection with the accompanying drawings.

[0018] Such as figure 1 with figure 2 As shown, this example provides an axial scalable automatic tightening mechanism including: a bottom plate assembly, a column 3, a cylinder assembly, an axial telescoping mechanism, a slide assembly, and a tightening gun assembly, the cylinder assembly through the column 3. At the top plate assembly, the axial telescoping mechanism is disposed on one side of the cylinder assembly, the axial telescoping mechanism is connected to the slide assembly, and the tightening gun assembly is disposed on the slide assembly. On; where the non-tightening state, the cylinder 13 of the cylinder assembly is extended; when the engine enters the station position, the cylinder 13 starts retract, the axial telescoping mechanism through the elastic compression drive said slip. When the tab is moved, the cylinder 13 continues to be ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com