Fabricated prefabricated slope protection device and construction method thereof

A prefabricated and slope block technology, which is applied in excavation, infrastructure engineering, construction, etc., can solve problems such as slow installation speed, inability to recycle, poor slope protection effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

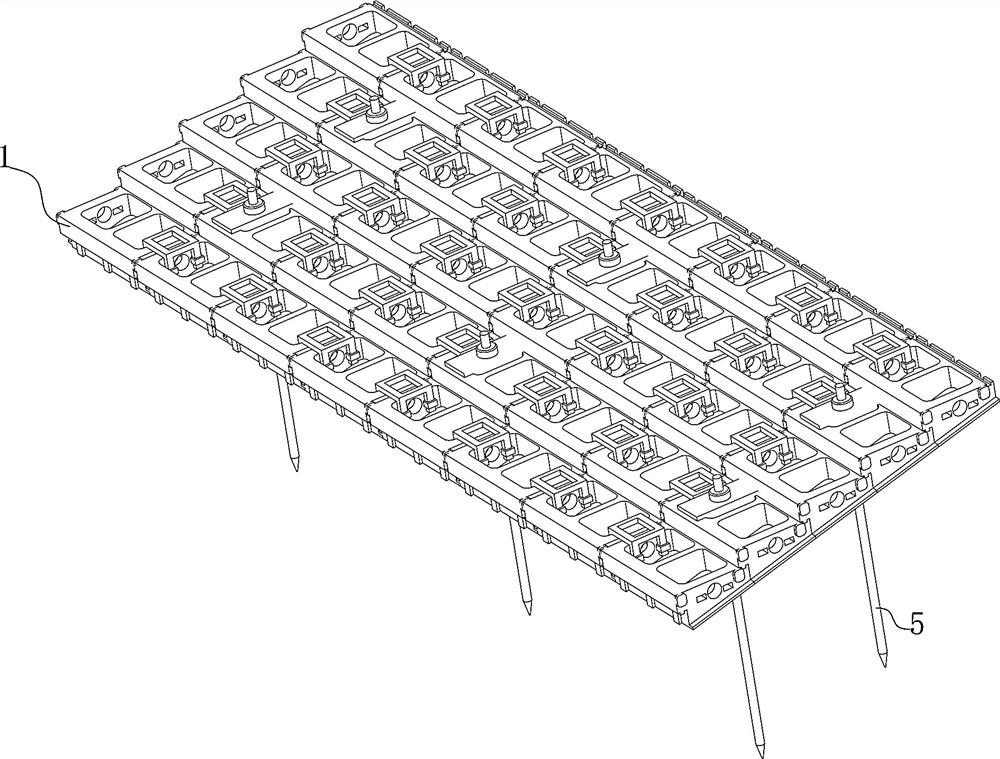

[0046] Such as Figure 1~10 As shown, an assembled prefabricated slope protection device includes a slope protection block 1, which is poured and formed at one time. The slope protection block 1 is provided with at least one planting hole, and both sides of the slope protection block 1 are provided with clamping devices. Connected by the clamping device on the side, the ends of a plurality of slope protection blocks 1 are connected through the horizontal fixing frame 9, the two ends of the slope protection blocks 1 are provided with ear plates, and the ear plates at the ends of two adjacent slope protection blocks 1 are connected to form a drainage groove 11 . Each single slope protection component is assembled and connected by clamping devices on both sides. After the assembly is completed, a continuous and complete three-dimensional structure is rapidly formed, such as Figure 1-4In the structure shown, the planting hole is used for planting vegetation 2, and the drainage ...

Embodiment 2

[0057] Further illustrate in conjunction with embodiment 1, as Figure 1-10 For the structure shown, before construction, release the excavation range of sideline piles and slope protection foundation grooves according to the design drawings, and set up protective piles 0.5m outside the excavation boundary, so as to facilitate inspection at any time during construction.

[0058] Excavation of drainage ditches for foundation trench 3 facilities, unqualified soft foundation within the scope of the foundation shall be replaced and filled with graded crushed stones.

[0059] The slope trimming is completed according to the design slope, and the slope surface should be flat and firm, and the effective compaction treatment should be carried out.

[0060] There are 8 sandstone layers at the bottom of the foundation, which are paved manually, and the paving width and thickness should meet the design requirements.

[0061] The upper foundation shall be poured with concrete pouring lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com