Cable take-up and pay-off device for automatic cable laying vehicle

A technology of automatic laying and retracting device, which is applied in the directions of transportation and packaging, transportation of filamentous materials, thin material processing, etc. On-site adaptability, simple structure, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

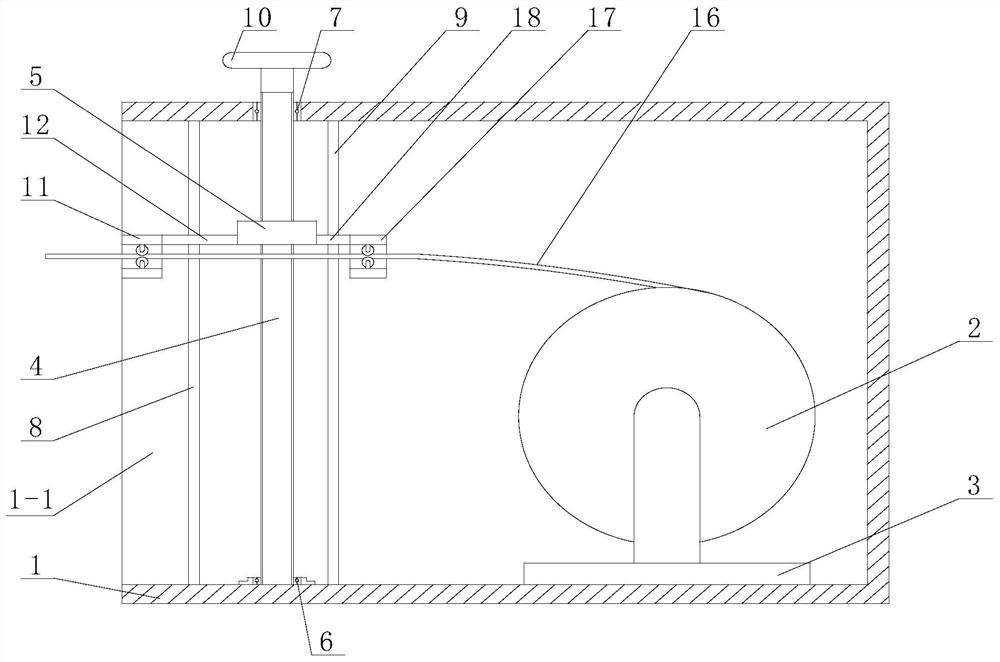

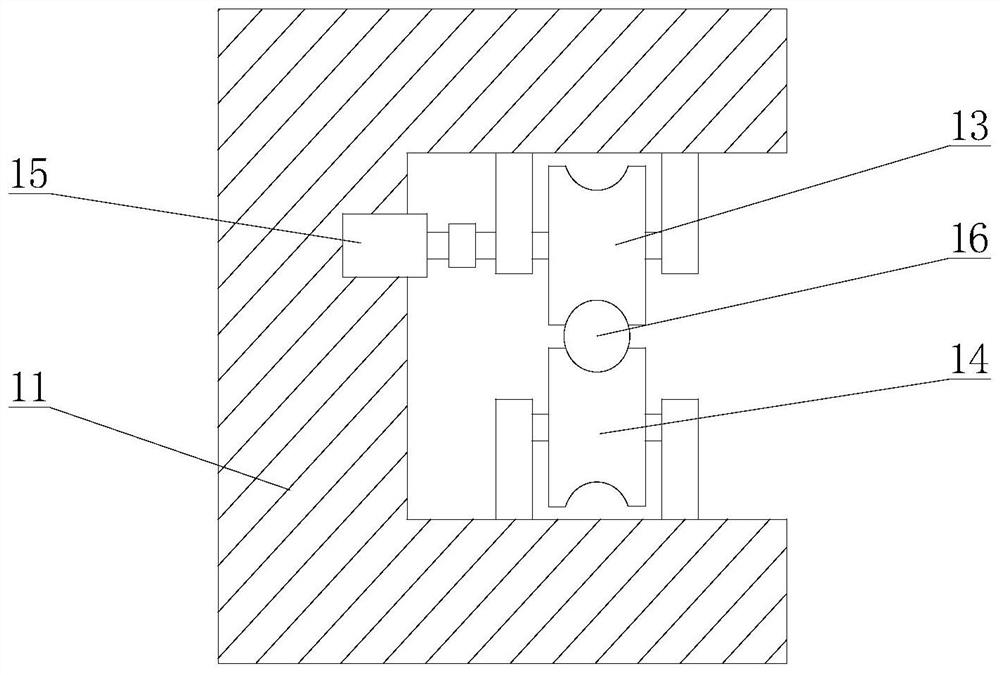

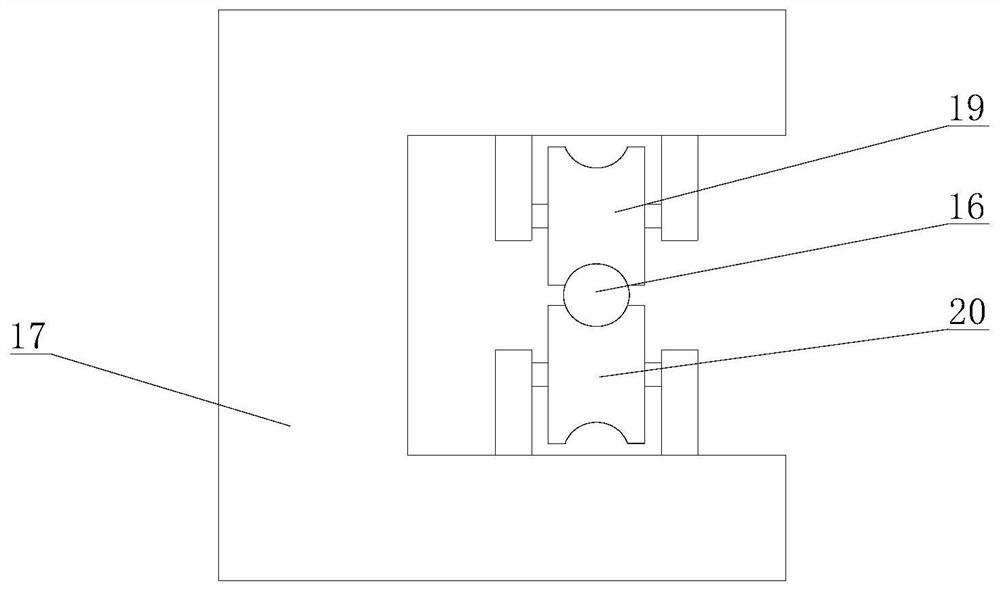

[0015] Specific implementation mode one: combine Figure 1 to Figure 3 This embodiment is described. The cable retracting device for an automatic laying cable vehicle described in this embodiment includes a housing 1, a cable reel 2, a base 3, a height adjustment mechanism, a cable guiding mechanism and a cable driving mechanism; The base 2 is fixedly installed in the housing 1, the cable reel 2 is installed on the base 3, the height adjustment mechanism is installed in the opening 1-1 of the housing 1, the cable driving mechanism and the cable The guide mechanism is sequentially installed on the height adjustment mechanism from outside to inside.

specific Embodiment approach 2

[0016] Specific implementation mode two: combination Figure 1 to Figure 3 This embodiment is described. The height adjustment mechanism of a cable retracting device for an automatic laying cable car in this embodiment includes a screw 4, a nut 5, a bearing seat 6, a bearing 7, a first guide rod 8 and a first guide rod 8. Two guide rods 9; the bearing 7 is embedded in the through hole at the top of the opening 1-1 of the housing 1, the bearing seat 6 is installed on the inner bottom surface of the opening 1-2 of the housing 1, and the upper end of the screw 4 is inserted Installed in the bearing 7, the lower end of the lead screw 4 is inserted into the bearing seat 6, the nut 5 is set on the lead screw 4, the first guide rod 8 is vertically arranged on the outside of the lead screw 4, and the first guide rod 8 The upper end is fixedly connected with the top surface in the housing 1, the lower end of the first guide rod 8 is fixedly connected with the bottom surface in the hous...

specific Embodiment approach 3

[0017] Specific implementation mode three: combination Figure 1 to Figure 3 To illustrate this embodiment, the height adjustment mechanism of the cable retracting device for an automatic cable laying vehicle in this embodiment further includes a rotating handle 10 , and the upper end of the lead screw 4 passes through the bearing 7 and is fixedly connected to the rotating handle 10 . Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com