Inverter type multifunctional power generation welding machine

A multi-functional, generator technology, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the problems of poor welding performance, single welding, low efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

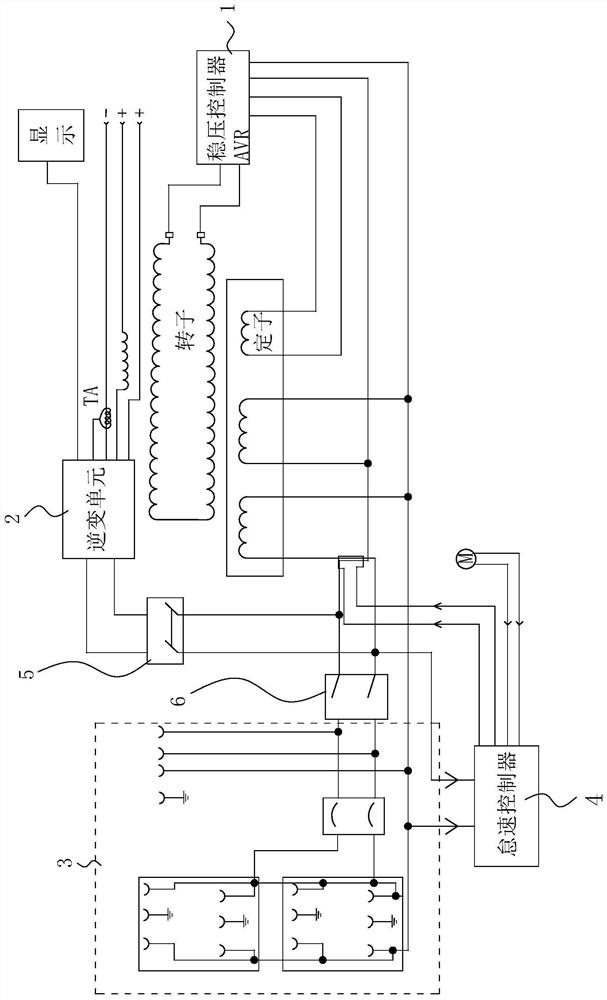

[0033] The following is attached Figure 1-3 The application is described in further detail.

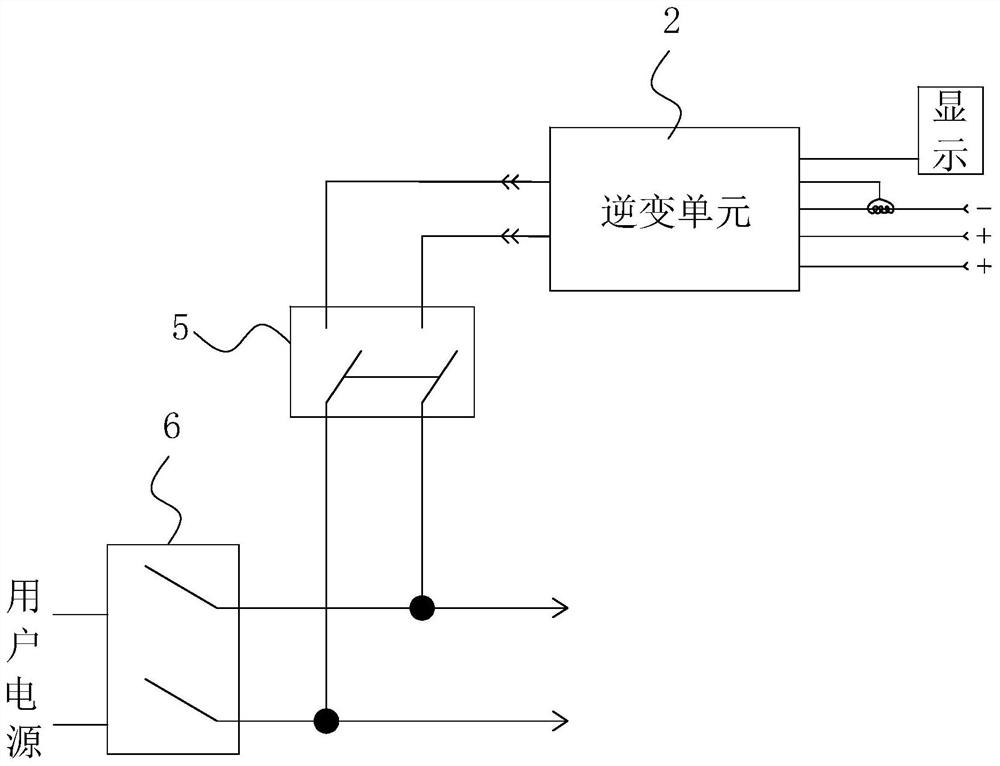

[0034] The embodiment of the present application discloses an inverter type multifunctional generator welding machine. refer to figure 1 , Inverter multifunctional generator welding machine includes: generator, transfer switch 5, air switch 6 and inverter unit 2. The generator outputs two alternating currents: the first alternating current output is sent to the inverter unit 2 through the transfer switch 5 for AC-DC conversion, and the second alternating current is output through the air switch 6 as the user's power supply. The inverter unit 2 inverts the first alternating current into direct current and steps down the voltage, and outputs multiple direct currents, wherein the first direct current is output to supply power to the display device of the welding machine, and the second direct current is output to supply power to the manual welder. After installing a wire feeder on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com