Cable construction equipment

A technology for construction equipment and cables, which is applied in the directions of cable laying equipment, cable installation, and ground cable installation, etc. It can solve the problems of mutual friction between cables and well edges, and achieve the effects of improving laying efficiency, good use effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

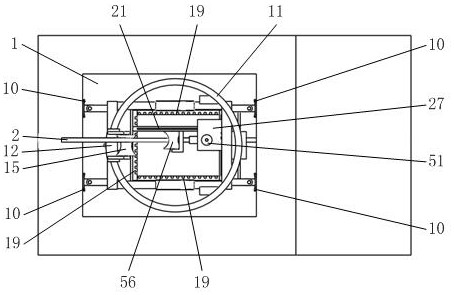

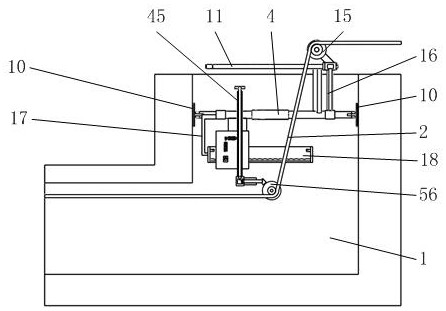

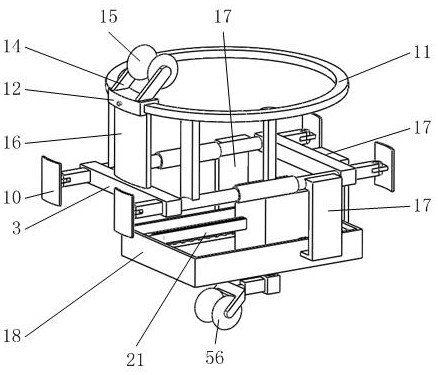

[0037] Such as figure 1 , 2 , 3, it includes a support rod A3, a telescopic rod structure 4, a foot 9, a guide ring 11, a sliding sleeve 12, a roller A15, a fixed plate B17, a support frame 18, a guide rod 21, a slide rod 45, and a transmission case 48 , shaft sleeve 49, shaft A50, shaft B54, roller B56, among which image 3 , 5 As shown, the two support rods A3 are connected by two telescopic rod structures 4 whose lengths are symmetrically distributed and can be locked. The two support rods A3 are symmetrically installed with four supporting feet 9 supporting the side wall of the shaft of the cable shaft 1 . Such as figure 2 , 3 As shown, a guide ring 11 with a vertical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com