Radiator assembly used for fixing electronic component

A technology of electronic components and radiators, applied in the field of radiator components, can solve the problems of inconvenient disassembly and assembly and low assembly efficiency, and achieve the effects of convenient disassembly and assembly, simple and convenient use, and improved assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

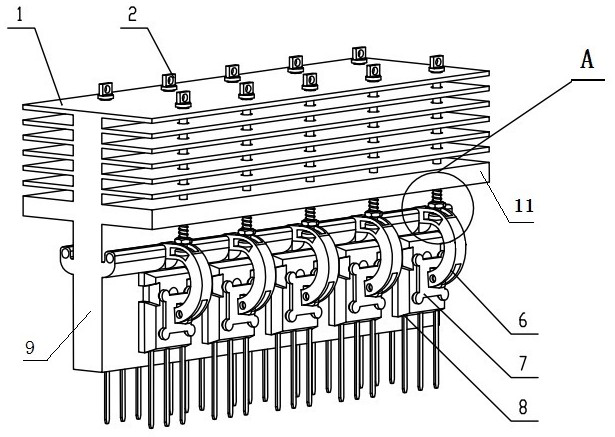

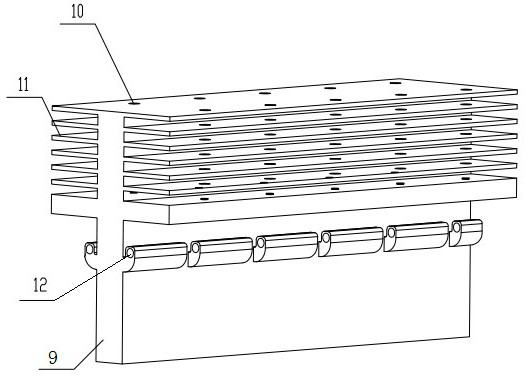

[0035] Such as Figure 1 to Figure 5 As shown, the electronic component to be cooled is a MOS tube 8, and the radiator assembly includes a radiator 1, which is a T-shaped radiator, and the radiator 1 is extruded from an aluminum profile, and the radiator 1 is composed of a base plate 9 and fins 11, the two sides of the substrate 9 are smooth planes with a thickness of 10mm, and MOS tubes 8 are attached to the planes on the left and right sides of the substrate, so as to realize the heat dissipation of the MOS tubes 8, and the distribution of the fins 11 and the radiator 1 for heat dissipation.

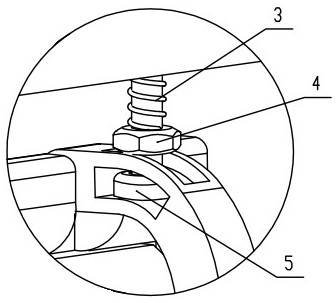

[0036] A turret 6 is hingedly mounted on the radiator 1, and the turret 6 is arc-shaped. A first hinge hole 60 is provided on the turret 6, a second hinge hole 12 is provided on the radiator 1, and a hinge shaft is inserted between the first hinge hole 60 and the second hinge hole 12 to hinge the turret 6 Connect to radiator 1.

[0037] The lower end of the turret 6 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com