Vibration reduction cutter bar for long overhanging cutting machining and using method thereof

A technology of cutting processing and cutter bar, which is applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of reducing the cutting surface quality, cutting vibration or even chatter, shortening tool life, etc., and achieves improved damping and vibration reduction effect, reducing the chance of cutting vibration, reducing the effect of deflection deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

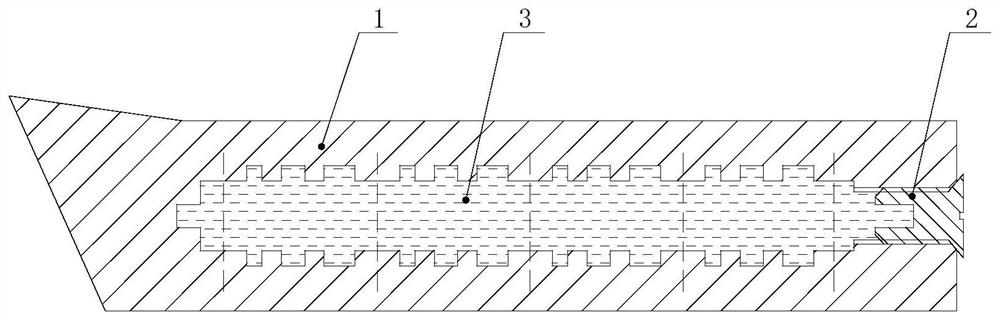

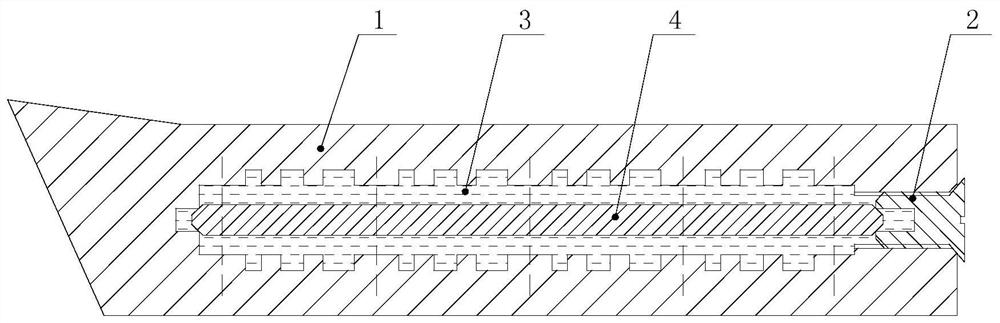

[0042] A vibration-damping tool holder for long overhang cutting, mainly including a tool holder body 1, a reinforcing core rod 4, a filling medium, a plugging piece and a magnetic pole plate 5, the filling medium adopts a magnetorheological fluid 3, and the sealing Blocking piece adopts countersunk head screw 2.

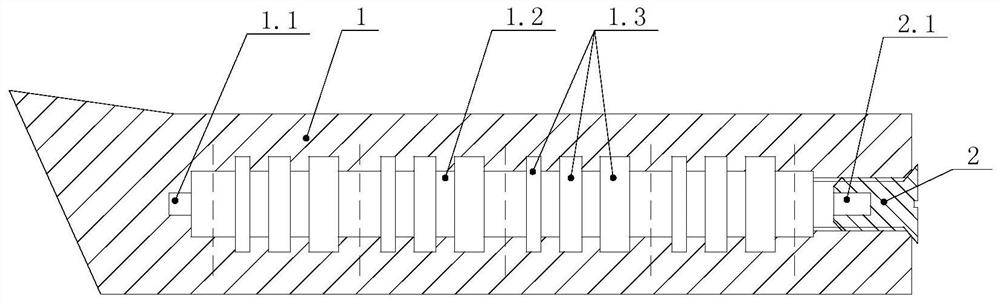

[0043] An inner cavity hole 1.2 is arranged at the inner center of the tool bar body, and multiple sets of periodic annular groove arrays 1.3 are formed on the hole wall of the inner cavity hole. Cooperate to form a closed cavity inside the cutter body.

[0044] Each group of annular groove arrays is composed of a plurality of annular grooves whose widths gradually become larger. In the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com