Uniformly gelatinizing gluing device for folding filter element

A technology of folding filter element and gluing device, which is applied in the direction of device and coating for coating liquid on the surface, can solve the problems of affecting product quality, heavy workload, slow gluing speed, etc., and achieves the fixing effect is simple, practical and lightening. Work load, fixed effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

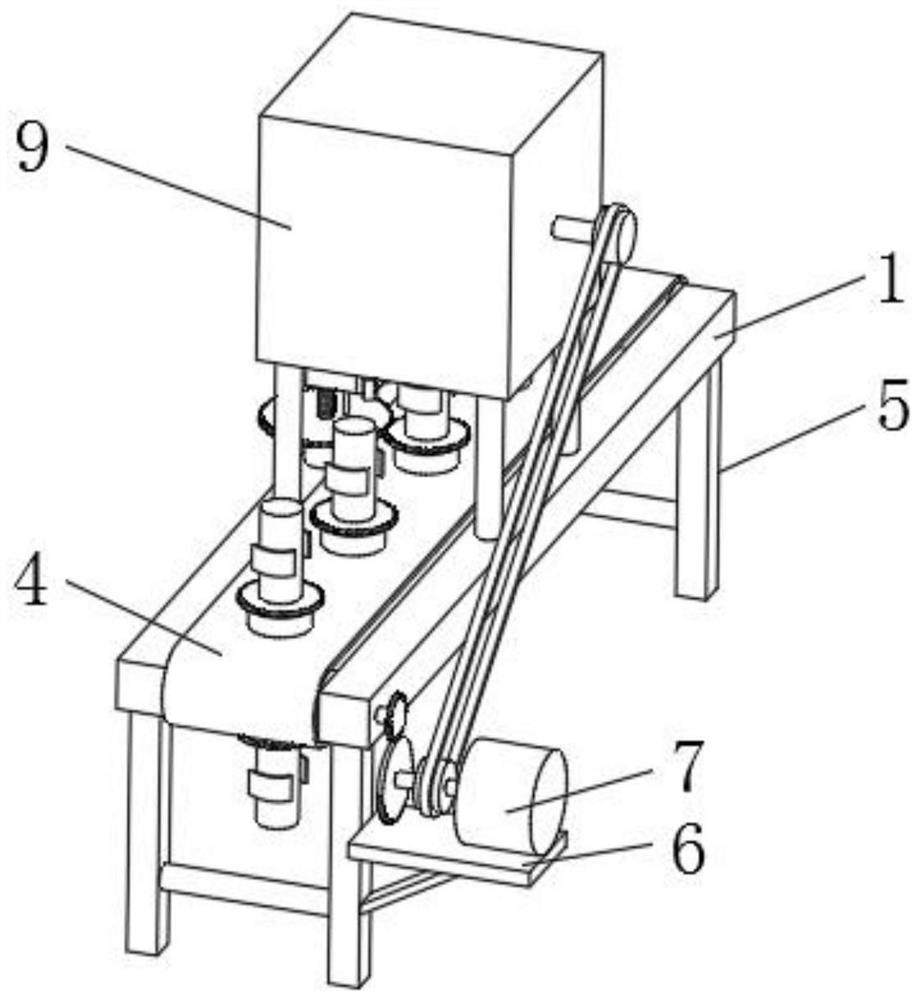

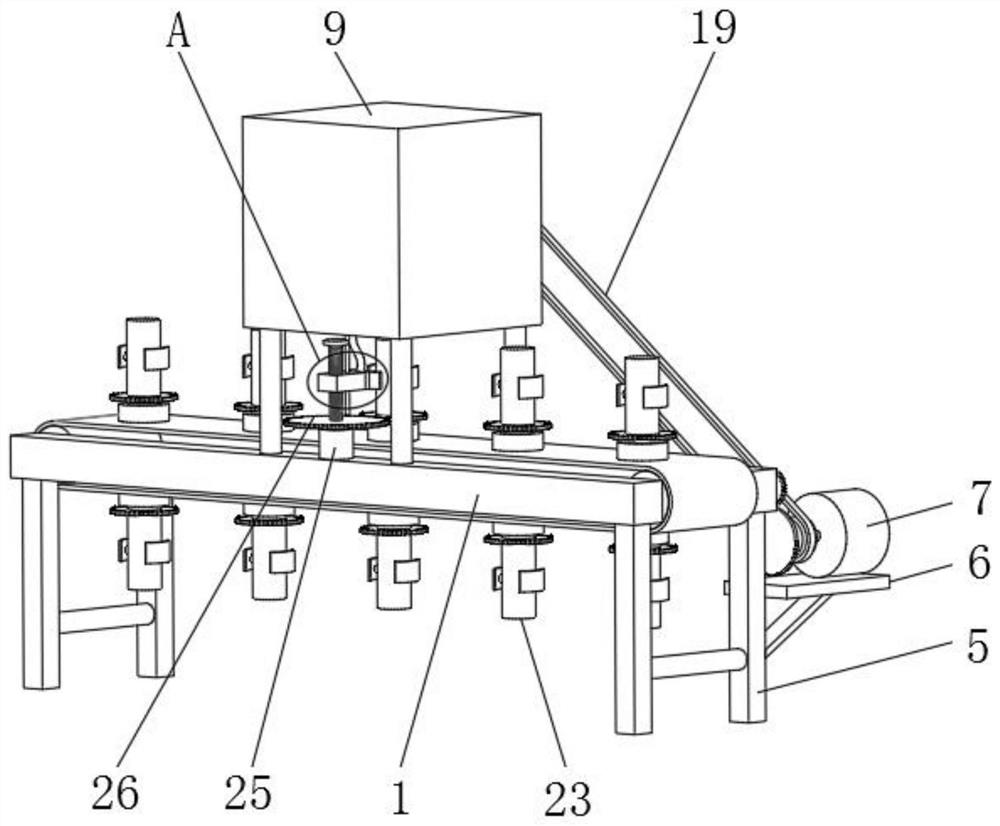

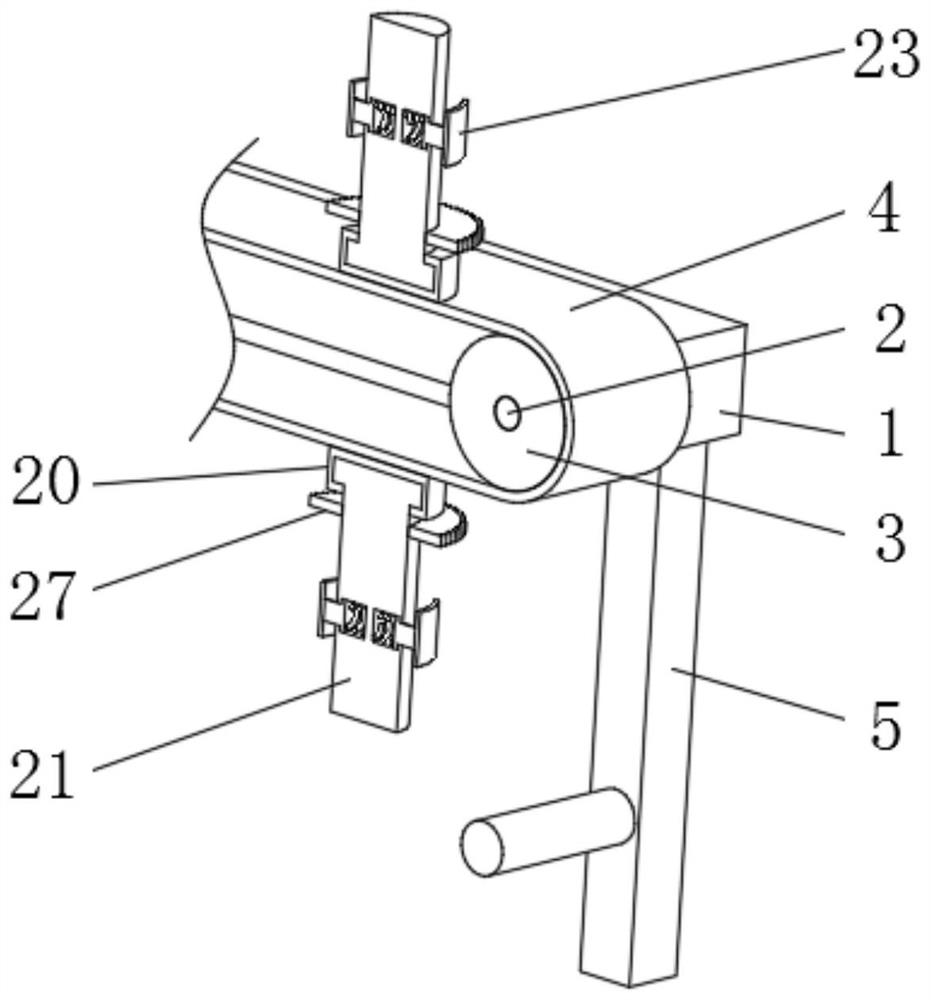

[0040] Example: Reference Figure 1-8 The shown gluing device for a pleated filter element with uniform gluing includes two horizontal square pillars 1, and the horizontal square pillars 1 can be any square pillar structure in the prior art, such as metal square pillars.

[0041] Two rotating shafts 2 are installed on the sides of the two horizontal square columns 1 that are close to each other, and the two rotating shafts 2 are fixedly sleeved with the transmission roller 3, and the same conveyor belt is installed on the two transmission rollers 3. 4. Two support columns 5 are fixedly installed on the bottom side of the two horizontal square columns 1. The support column 5 can be any metal vertical column in the prior art, which is welded to the bottom side of the horizontal square column 1. fixed.

[0042] One side of one of the support columns 5 is fixedly installed with a fixed plate 6, and the top side of the fixed plate 6 is fixedly installed with a rotating motor 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com