Double-layer rail vibration reduction fastener with blocking shoulder

A vibration-damping fastener and track technology, which is applied to tracks, roads, fixed rails, etc., can solve the problems of easy wear and tear of connecting parts, and achieve the effects of overcoming easy wear, reducing noise and rail wear, and simplifying locking methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with examples.

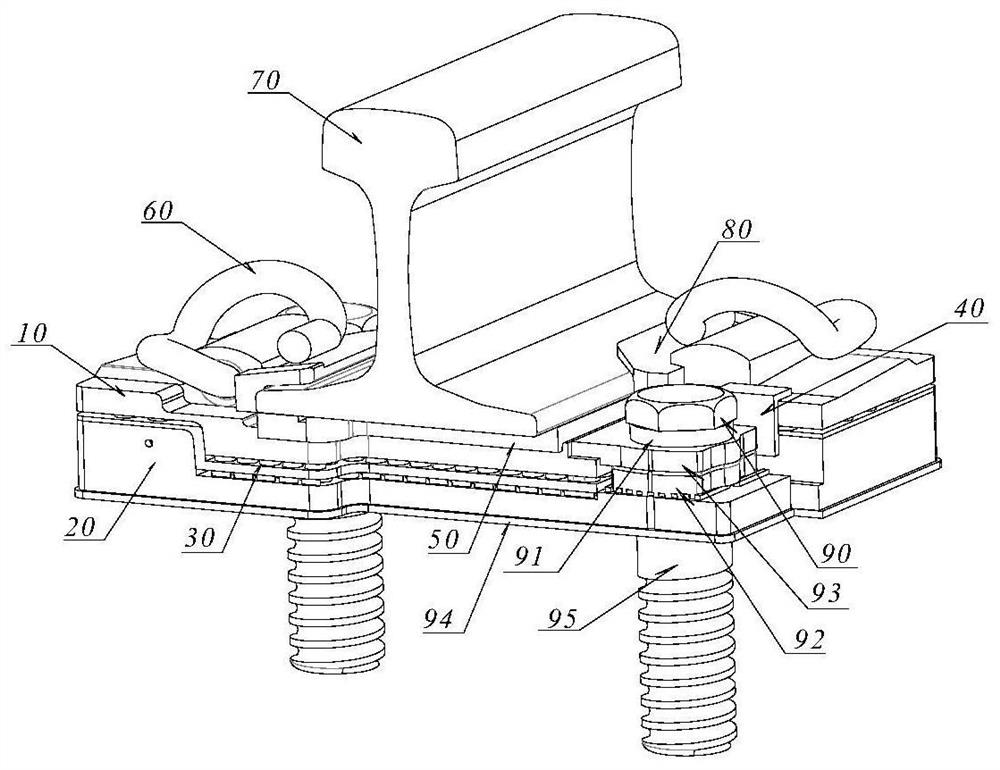

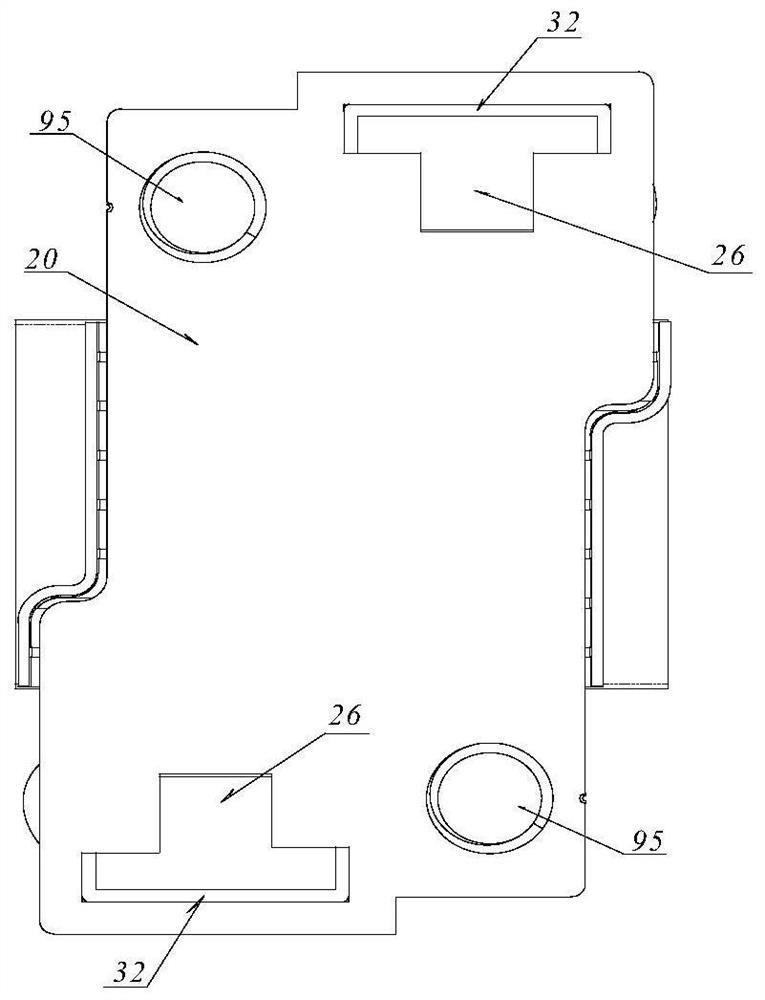

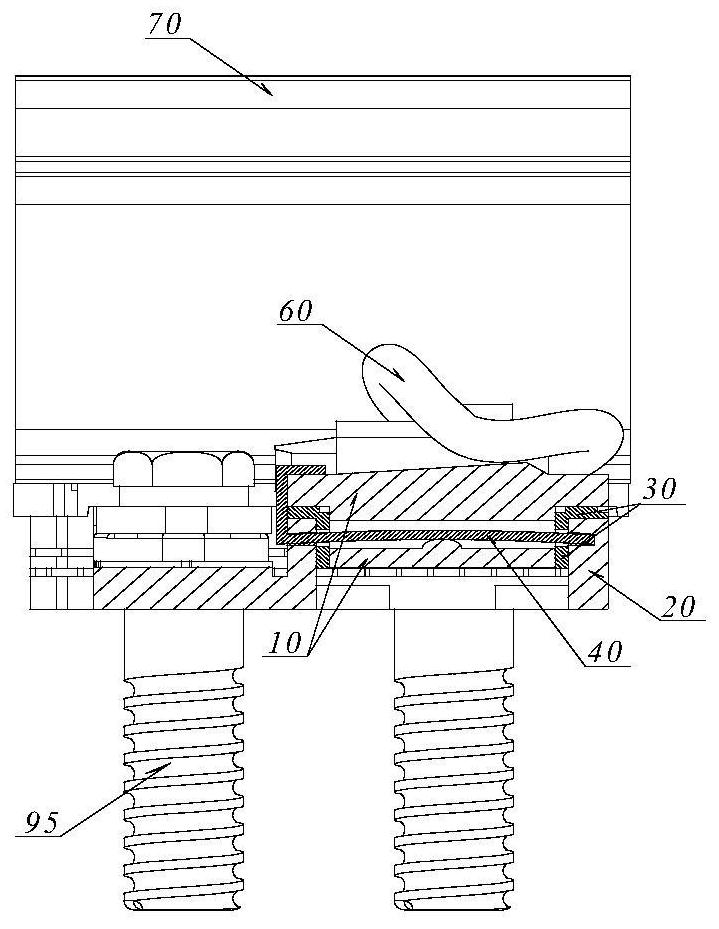

[0028] refer to figure 1 , figure 2 with image 3 , a double-layer track damping fastener with shoulders, including a lower insulating backing plate 94, a lower iron backing plate 20, a vibration isolation backing plate 30 and an upper iron backing plate 10 stacked sequentially from the sleeper surface from bottom to top . Both sides of the vibration isolation backing plate 30 and the lower iron backing plate 20 have corresponding square limit shoulders, the bottom of the upper iron backing plate 10 is provided with a lower convex portion, and the two sides of the rail 70 are provided with vertically passing through the lower iron backing plate. The backing plate 10, the vibration isolation backing plate 30 limit the shoulder and the lower convex portion of the upper iron backing plate 20 and the locking pin 40 that locks it vertically. The lower iron backing plate 20 and the vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com