A cross-scale numerical simulation method based on the wall slip effect of micro-nano grooves

A numerical simulation and wall slip technology, applied in electrical digital data processing, instrumentation, design optimization/simulation, etc., can solve the problems of difficult numerical simulation of global flow field, expensive calculation cost, etc., and achieve the effect of improving design and calculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

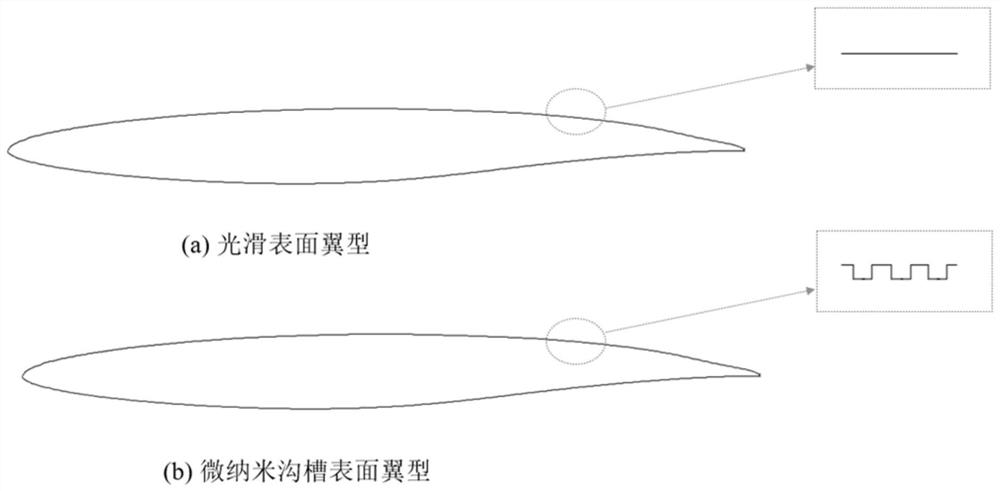

[0040] The invention provides a cross-scale numerical simulation method based on the micro-nano groove wall slip effect.

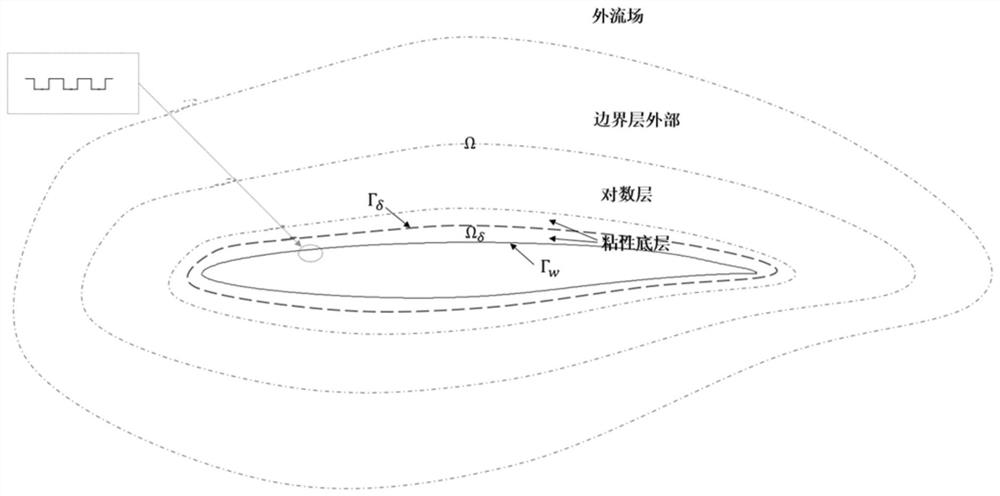

[0041] Step (1): Regional division of the global flow field

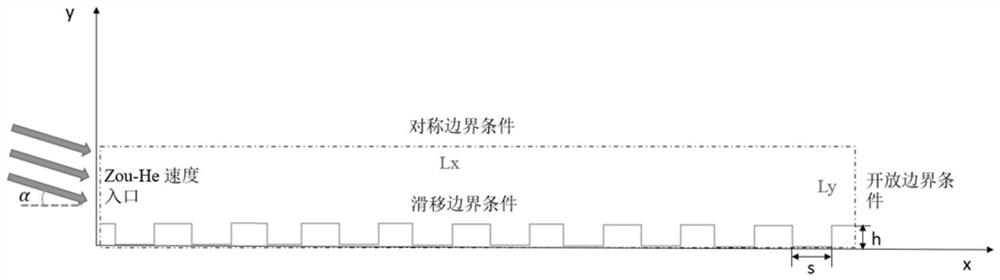

[0042] Such as figure 1 As shown, in order to simulate the global flow field Ω of an airfoil with micro-nano grooved surface structure, we propose a domain decomposition method to solve this multi-scale problem. The global flow field is divided into the viscous bottom layer, the logarithmic layer, the outer boundary layer, and the outer flow field. The actual boundary of the flow field is Γ w , denoted with an artificial internal boundary Γ δ (within the first grid point on the wall) the microscopic near-wall region that lies within the viscous substratum. The global problem is then decomposed into two problems: 1) Based on the microscopic simulation data, the microscopic near-wall region is replaced by a proxy model of the micro-nano groove surface structure. 2) The modified wall boundar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com