Vibration prevention and reduction structure

A technology of mounting seat and connecting rod, applied in the direction of low internal friction spring, etc., can solve the problems of vibration absorption, vibration generation, equipment damage, etc., to ensure the effect of shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

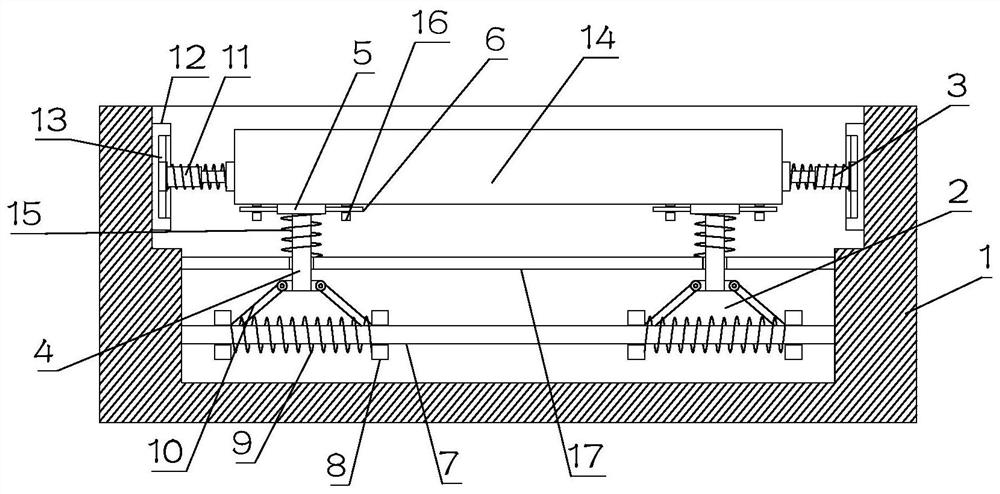

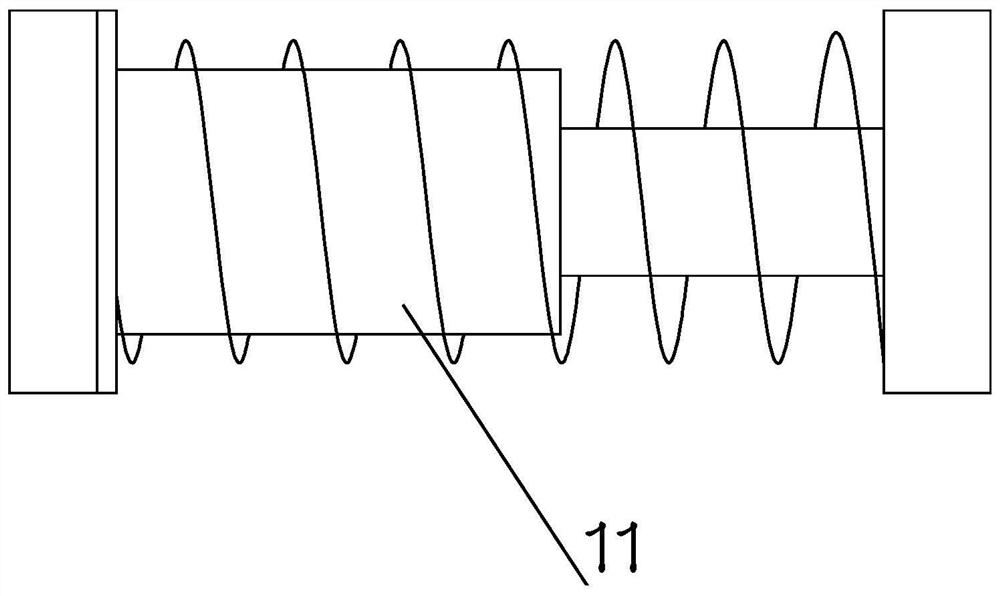

[0022] see Figure 1~3 , in Embodiment 1 of the present invention, it is a structural diagram of a shock-proof and shock-absorbing structure provided by the embodiment of the present invention, including: a base 1 and a mounting seat 14, the mounting seat 14 is arranged in the inner groove of the base 1, and the Mounting seat 14 is used for installing equipment;

[0023] Both sides of the bottom of the mounting seat 14 are respectively installed on the bottom of the base 1 through the first shock absorbing assembly 2, and the two sides of the first shock absorbing assembly 2 are respectively connected to the inner side wall of the base 1 through the second shock absorbing assembly 3; One end of the second damping assembly 3 is fixedly installed on the mounting base 14, and the other end is slid up and down and arranged on the side wall of the base 1;

[0024] The first damping assembly 2 includes a connecting rod 4, the upper end of the connecting rod 4 is fixedly installed w...

Embodiment 2

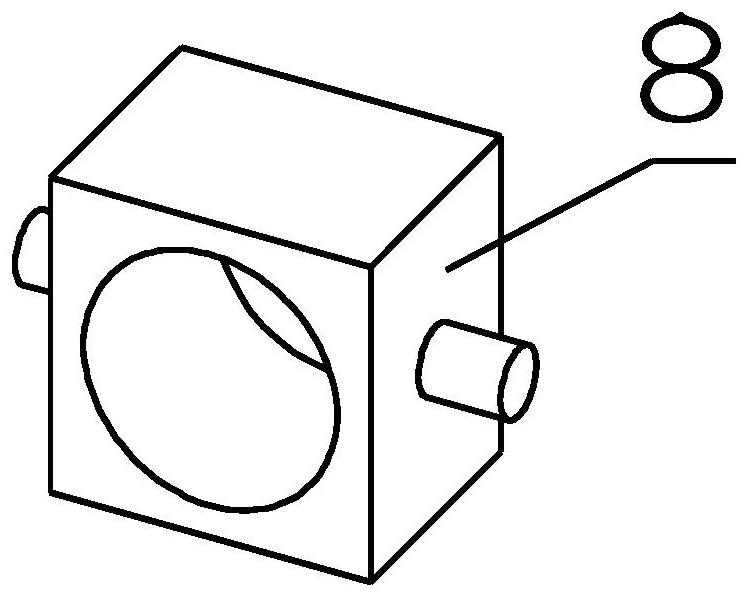

[0027] see Figure 1~3 The main difference between this embodiment 2 and embodiment 1 is that the two sides of the lower end of the connecting rod 4 are respectively rotated and installed with connecting rods 10, and the ends of the connecting rods 10 on both sides away from the connecting rod 4 are respectively rotated and sleeved in two slip rings. 8, the two slip rings 8 are slidingly sleeved on the second slide bar 7, and the second slide bar 7 is fixedly installed inside the base 1, and the two slip rings 8 are elastically sleeved on the second slide bar 7 , and then when the connecting rod 4 is vibrated, the vibration is transmitted to the slip ring 8 for secondary absorption, thereby realizing two-stage shock absorption.

[0028] The two slip rings 8 at the bottom of the connecting rod 4 are connected by the first elastic member 9, and the first elastic member 9 is sleeved on the outside of the second slide bar 7, and then the two slip rings 8 are elastically mounted on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com