A Horizontal Rotation Mechanism Applicable to Off-Position Movable Hinge Seat of Hanging Net Rod

A technology of horizontal rotation and net poles, which is applied in building construction, building material processing, construction, etc., can solve the problems of large frame area and weight of the new type of falling object protection net, and achieve the effect of eliminating mechanical interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical scheme and technical effect of the present invention more obvious and easy to understand, the following will be described in detail in conjunction with the accompanying drawings.

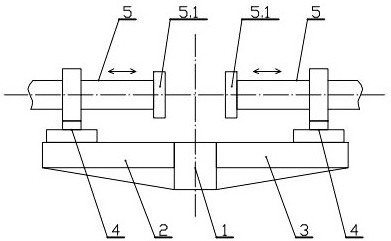

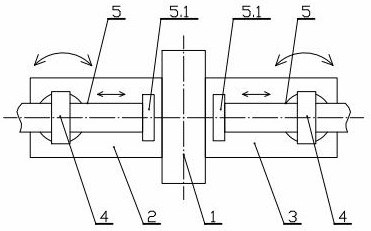

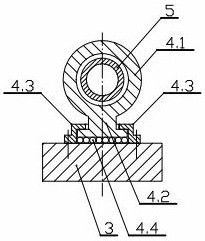

[0017] like Figure 1 to Figure 3 As shown, the horizontal rotation mechanism of the present invention, which is suitable for the different position movable hinge seat of the hanging net rod, includes an intermediate seat body 1 for connecting with the end of the horizontal ejector rod, and the left and right sides of the intermediate seat body 1 are respectively provided with The left platform 2 and the right platform 3 are symmetrically arranged on the left and right sides of the middle base body, and the left platform and the right platform are fixedly connected with the middle base body.

[0018] The left and right platforms are respectively provided with a horizontal rotation mechanism 4, and the horizontal rotation mechanism is symmetrically arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com