Raw material preheating equipment for non-woven fabric manufacturing

A non-woven fabric and raw material technology, which is applied in the field of non-woven fabric manufacturing raw material preheating equipment, can solve problems such as uneven melting, and achieve the effects of increasing preheating effect, preventing heat waste and increasing moving speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

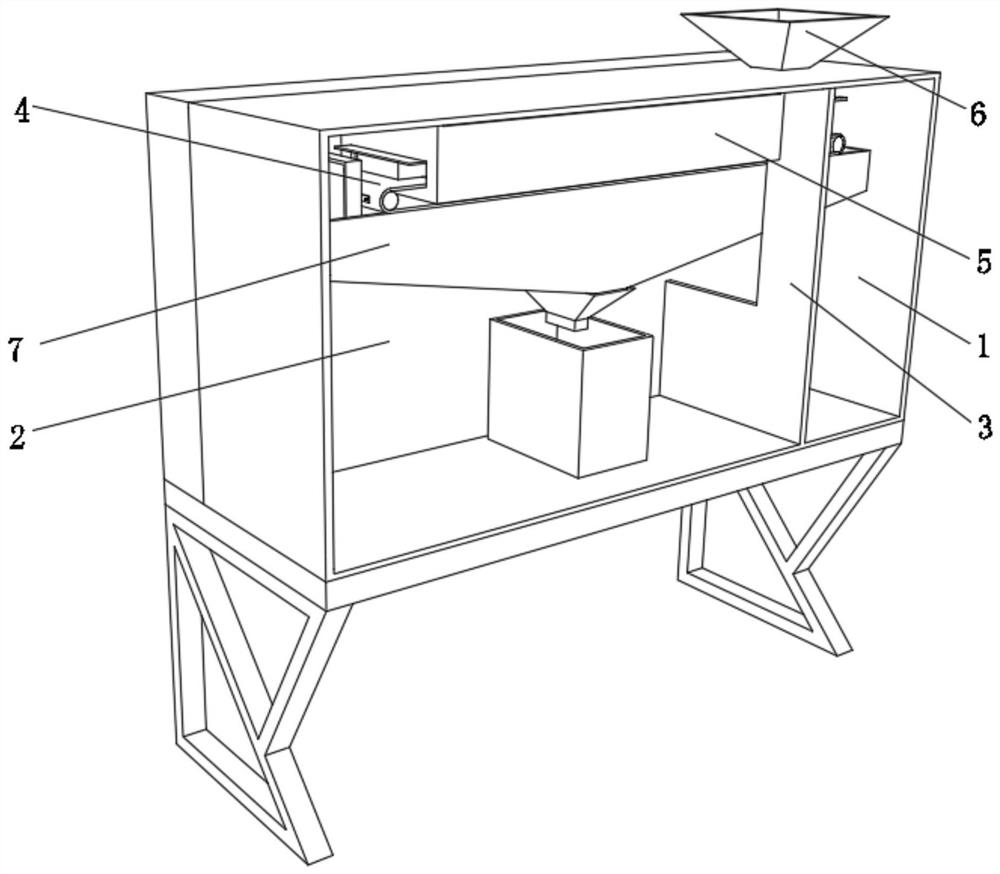

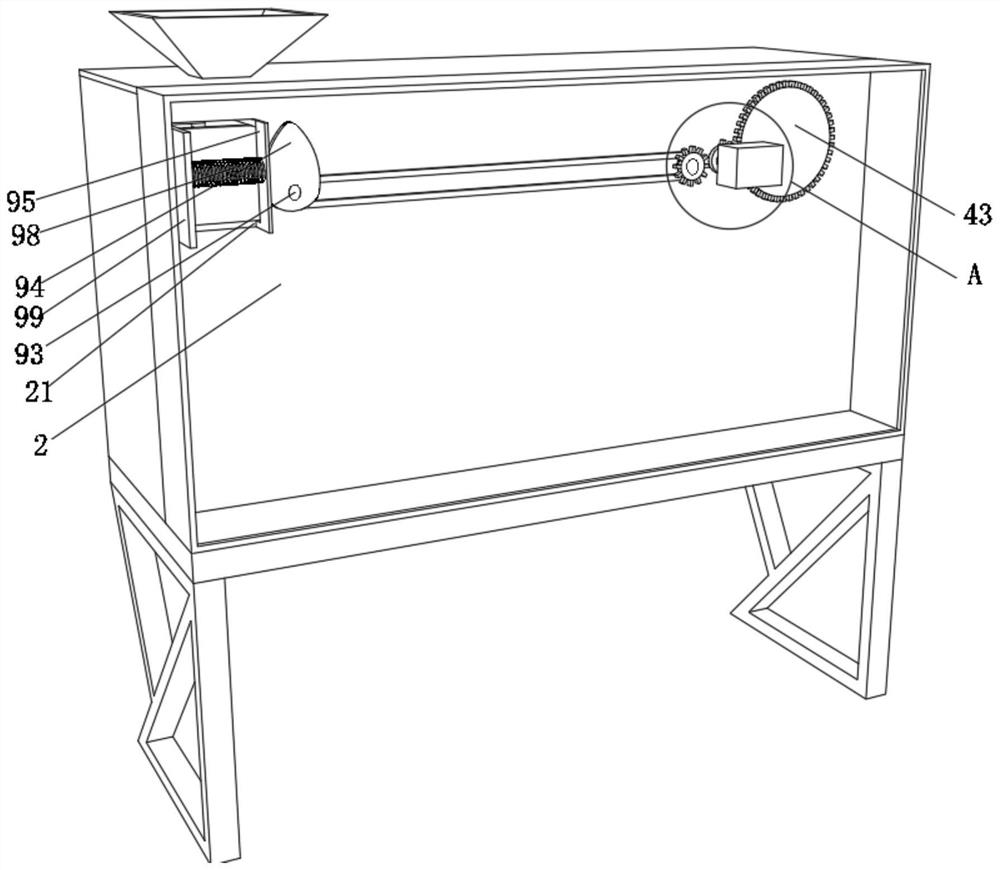

[0032] A raw material preheating equipment for non-woven fabric manufacturing, such as Figure 1-Figure 4 As shown, including the main box 1, the inside of the main box 1 is welded with a partition plate 2, the front part of the partition plate 2 is welded with a partition plate 3, the rear side of the partition plate 2 is provided with a transmission mechanism 4, and the front part of the partition plate 2 A preheating mechanism 5 is provided on the left side of the partition plate 3, a feeding mechanism 6 is provided on the upper surface of the main box 1 at the front of the partition plate 2, and a collector is welded on the inner wall of the main box 1 at the front of the partition plate 2. Box 7.

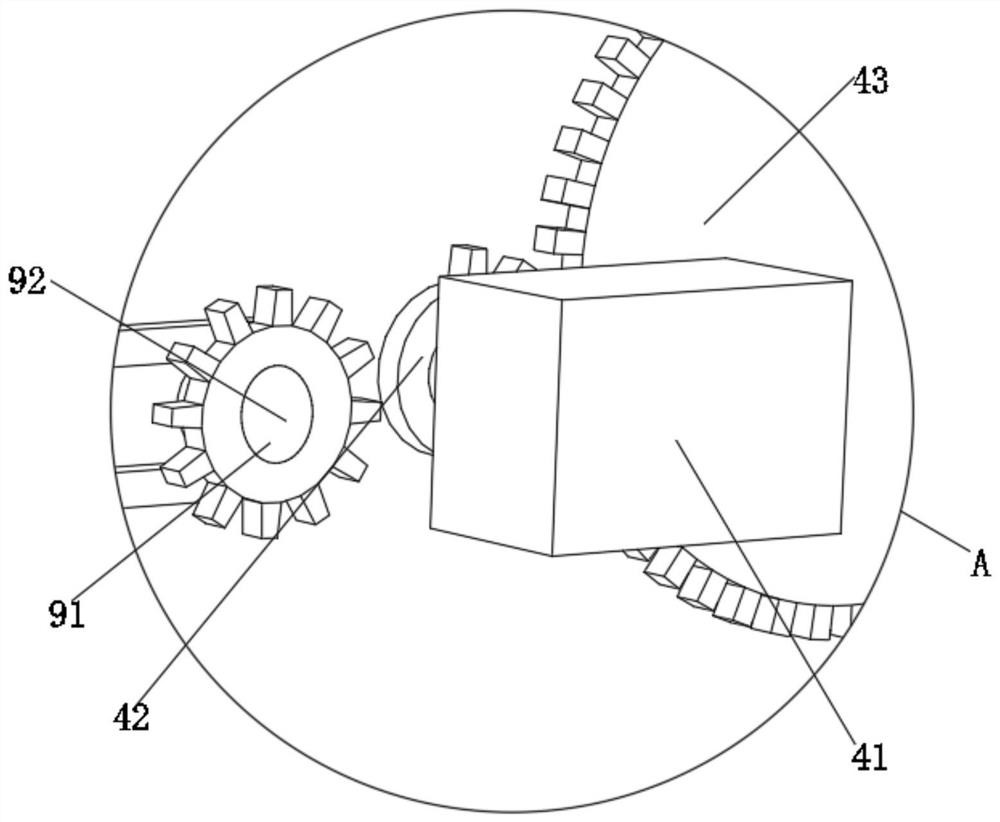

[0033] In this embodiment, the transmission mechanism 4 includes a motor unit 41. The output end of the motor unit 41 is connected to the rear part of the isolation plate 2 through a half gear 42. The surface of the half gear 42 is meshed with a first transmission gear 43. The ...

Embodiment 2

[0039] Such as Figure 5-Figure 8 As shown, on the basis of Embodiment 1, in this embodiment, the feed mechanism 6 includes a feed box 61, an inclined plate 62 is welded inside the feed box 61, and a slide plate 63 is welded on the right side of the feed box 61 , the lower surface of the barrier plate 97 is slidably connected with the surface of the slide plate 63, the right side of the slide plate 63 is fixed with the right wall welding machine inside the main box 1, the surface of the slide plate 63 is provided with grooves, and the feed box 61 can facilitate the feeding of raw materials. Feed box 61 enters in the material storage box on the conveyor belt 45 surface below feeding mechanism 6, and inclined plate 62 can make slide plate 63 move to the left side and can not talk about raw material and the inwall clamping of feed box 61, can be convenient to prevent. The raw material slips from the stuck gap into the collection tank, thereby affecting the quality of the melted r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com