Jacking anti-tipping alarm system of self-elevating tower crane

A technology for tower cranes and alarm systems, applied to cranes, load hanging components, safety devices, etc., can solve problems such as frequent alarms, inability to effectively operate tower cranes, and failure to reach, and achieve the effect of avoiding dangerous operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

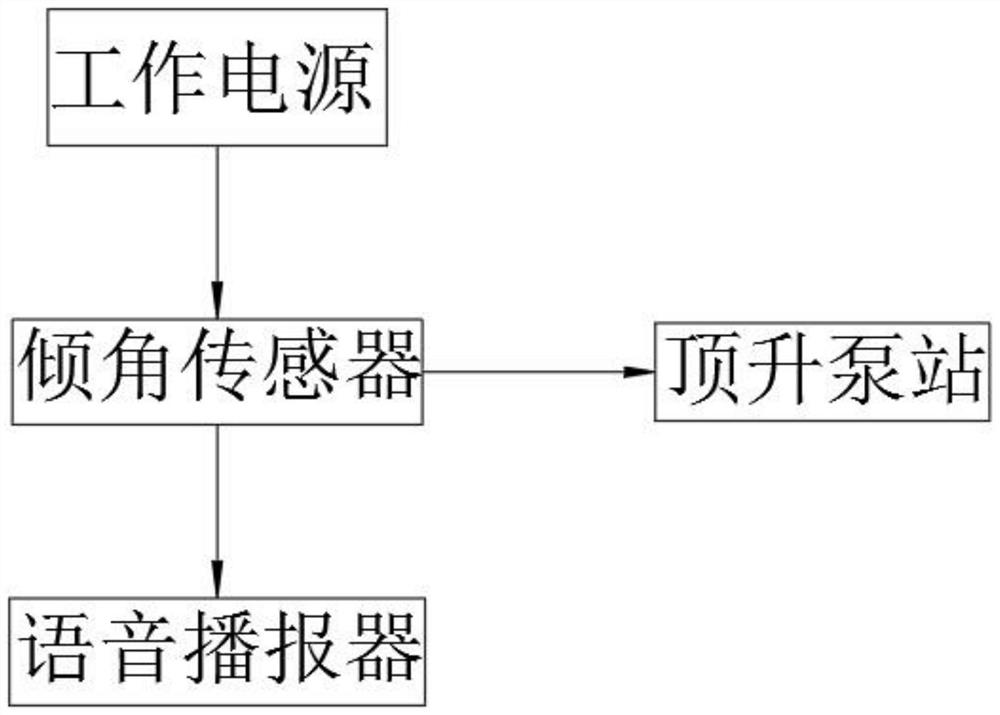

[0016] Such as figure 1 As shown, a self-elevating tower crane jacking anti-tipping alarm system includes an inclination sensor, a working power supply, a voice announcer, and a jacking pump station. The working power supply is associated with the power supply line of the jacking pump station, and the signal output line is connected to The inclination sensor is installed on the slewing tower on the upper part of the tower crane, and is electrically connected with the jacking pump station, the voice announcer and the working power supply respectively.

[0017] The working principle of the present invention is as follows: the present invention installs an inclination sensor on the slewing tower at the upper part of the tower crane, and incorporates the signal output circuit of the inclination sensor into the alarm circuit of the tower crane. Detect the verticality of the upper part of the tower crane during the jacking and knotting operation. When the verticality of the shaft ce...

Embodiment 2

[0020] On the basis of Embodiment 1, the inclination sensor adopts a relay output dual-axis inclination sensor with a resolution of 0.01°.

Embodiment 3

[0022] On the basis of Embodiment 1, the inclination sensor calculates the safe inclination angle according to the overturning moment when it is installed and disassembled, and uses a spirit level to calibrate and compare the inclination of the upper part of the tower with the horizontal plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com