Textile cloth winding device with dust removal function

A rolling device and cloth technology, applied in textiles and papermaking, winding strips, transportation and packaging, etc., can solve the problems of cloth not having the function of dust removal, affecting product appearance, unfavorable processing, etc., and achieve a good user experience , Simple structure, stable transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

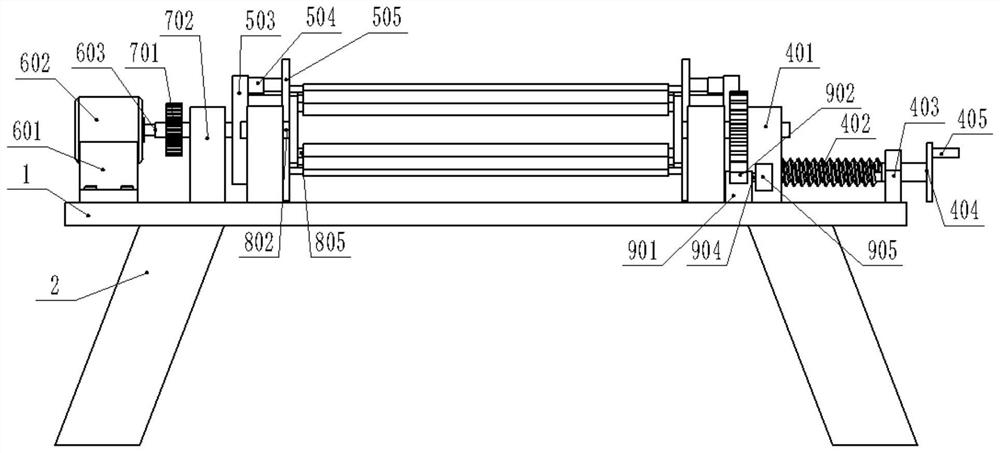

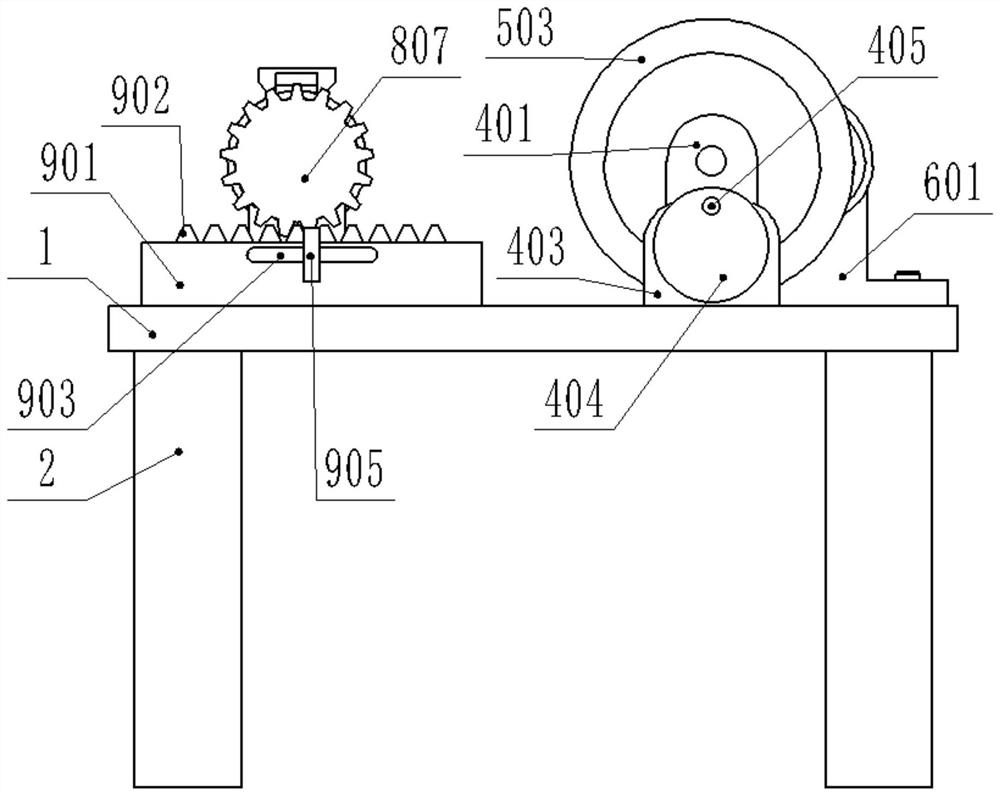

[0023] Example 1: Please refer to Figure 1-4 , a cloth winding device with dust removal function for textile use, including a workbench 1, support legs 2 are fixedly connected to the bottom of the workbench 1, front, rear, left, and right, and a chute 3 is opened on the right side of the upper middle part of the workbench 1 ;

[0024] The chute 3 is slidably connected with the installation mechanism 4. When in use, the handle 405 is turned, which then drives the turntable 404 to rotate, and then the screw rod 402 is turned, and then the sliding block 401 is moved, and then the right horizontal axis 501 is aligned with the left horizontal axis. 501 is disengaged, the cloth tube is sleeved on the surface of the reel 502, and the handle 405 is turned to restore the reel 502 on both sides to its original position;

[0025] The installation mechanism 4 is rotatably connected with the winding mechanism 5, and the hydraulic telescopic shaft 504 is opened, so that the pressure plate...

Embodiment 2

[0036]Embodiment 2: This embodiment is a further improvement of the previous embodiment: the connection method between the limiting block 901 and the workbench 1 is welding.

[0037] The working principle of the present invention is: turn the handle 405 during use, and then drive the turntable 404 to rotate, and then make the screw rod 402 rotate, and then make the sliding block 401 move, and then make the right horizontal axis 501 and the left horizontal axis 501 separate, and the cloth The tube is sleeved on the surface of the reel 502, and the handle 405 is turned to return the reel 502 on both sides to its original position; the hydraulic telescopic shaft 504 is opened to move the pressure plate 505 relatively, and then the two ends of the cloth tube are pressed tightly, and the cloth One side passes through the dust suction cylinder 806 and is fixed on the cloth cylinder sleeved on the surface of the winding cylinder 502, pushing the push plate 905 and then moving the rack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com