Buffer mechanism

A buffer mechanism and buffer bin technology, applied in the field of buffer mechanism, can solve the problems of high labor cost, high production cost, low production efficiency, etc., and achieve the effects of increasing management efficiency, improving efficiency, and improving management efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

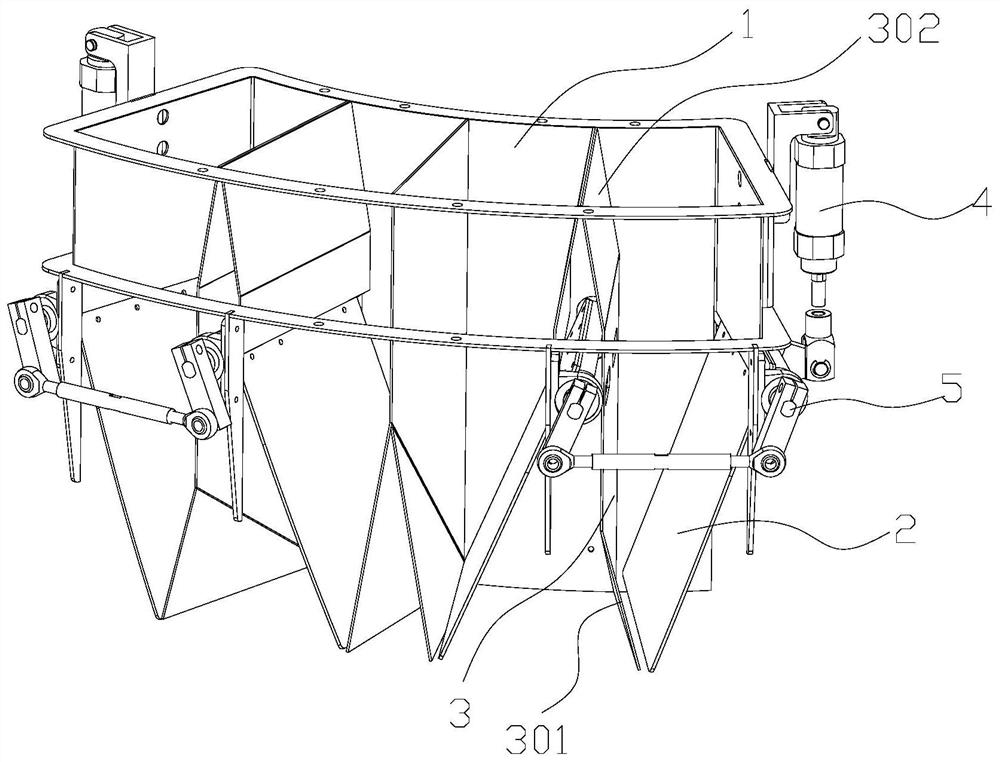

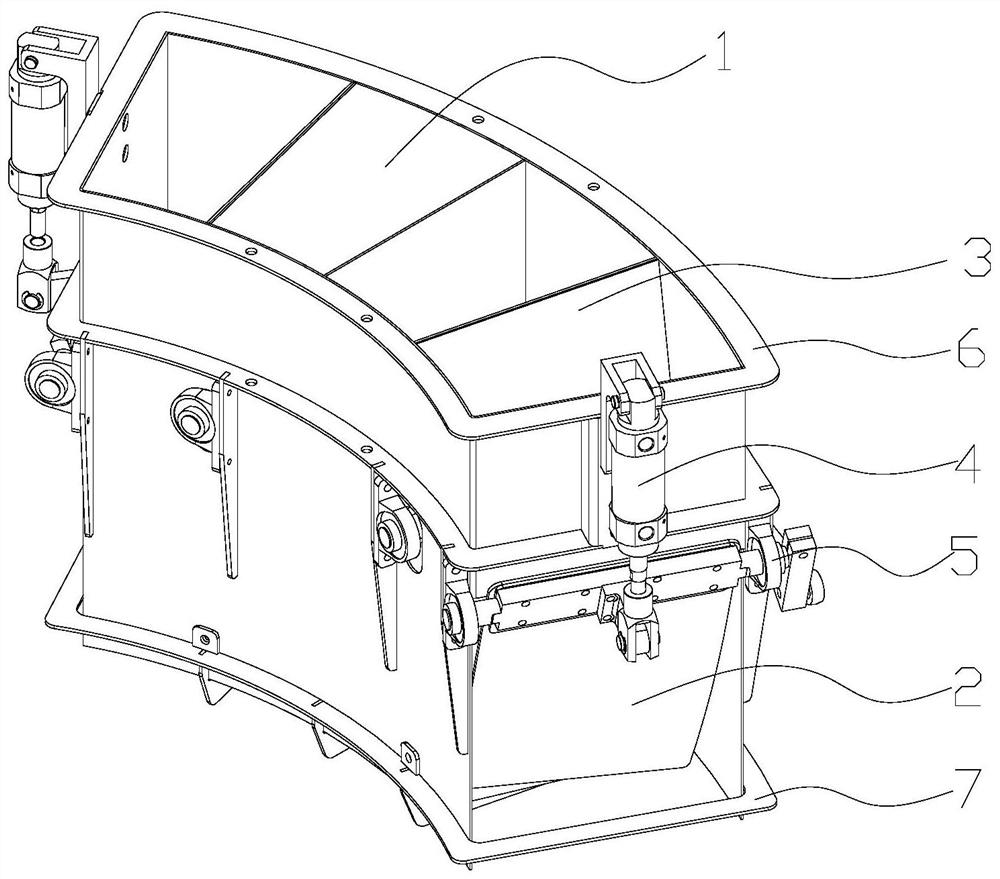

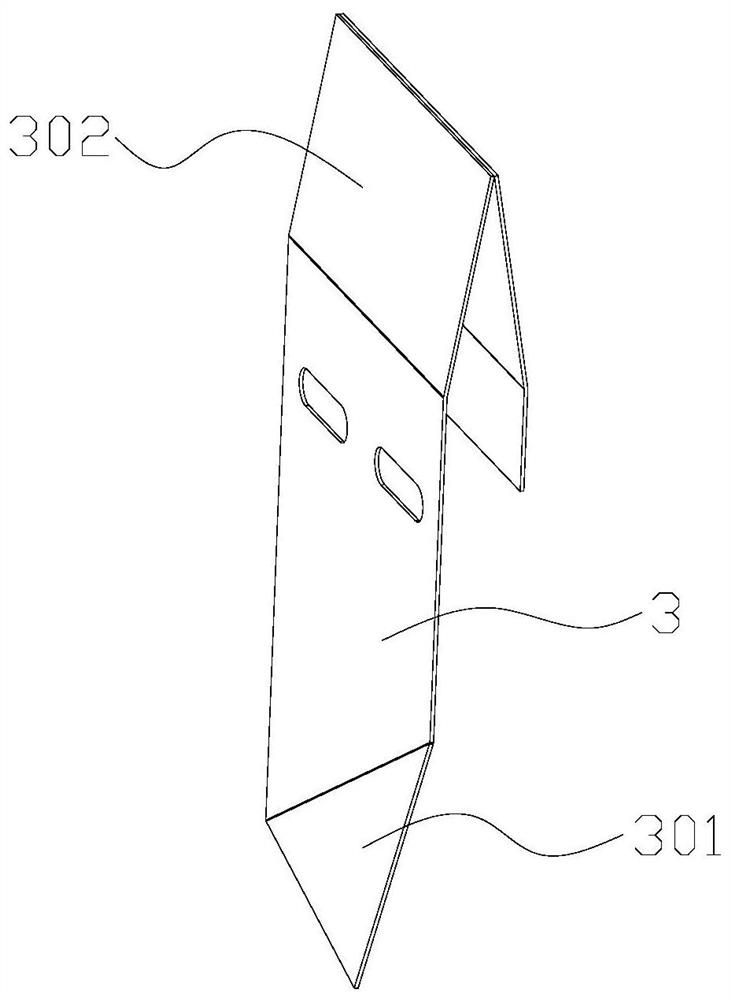

[0078] Single opening plate structure, a single cylinder drives multi-links to open and close the opening plate;

[0079] The specific working method is that after the bobbins are filled with the buffer chamber in sequence, the opening plate cylinder starts to move, and the opening plate cylinder drives the rocker arm of one side of the opening plate to realize the opening and closing of the opening plate.

Embodiment 2

[0081] Two open plate cylinders are used to independently control the opening and closing of the corresponding open plate. The two open plate cylinders are respectively fixed on both sides of the buffer body. After the bobbin is fully filled with the buffer chamber, the open plate cylinder starts to move, and the open plate cylinder drives to open. The plates are opened toward both sides to realize the simultaneous opening and closing of the two open plates.

Embodiment 3

[0083] Two opening plate cylinders are used to independently control the opening and closing of the two opening plates. The two opening plates are one-sided structure, connected by connecting rods, and the opening plate cylinders are respectively fixed on both sides of the buffer body. Finally, the opening plate cylinder starts to move, and the opening plate cylinder drives the opening plates to open toward both sides, so that the four opening plates are simultaneously opened and closed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com