Automatic die cutting mechanism

A die-cutting knife and frame technology, applied in metal processing, etc., can solve the problems of lack of precision, high cost, cumbersome die-cutting steps, etc., and achieve the effect of improving the adhesion firmness, simple operation mode, and realizing the effect of speed regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. It should be noted that relative terms such as "first", "second" and so on may be used to describe various components, but these terms do not limit the components. These terms are only used to distinguish one component from another. For example, without departing from the scope of the present invention, a first component may be called a second component, and a second component may similarly be called a first component. The term "and / or" refers to any one or more combination of related items and described items.

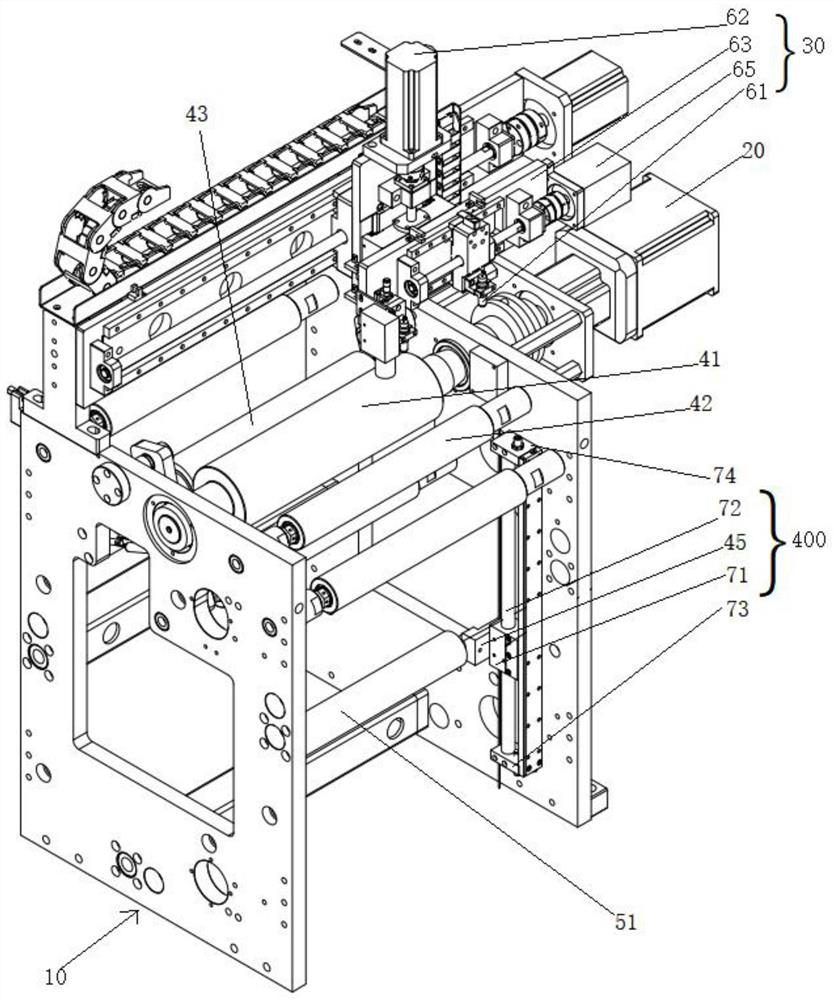

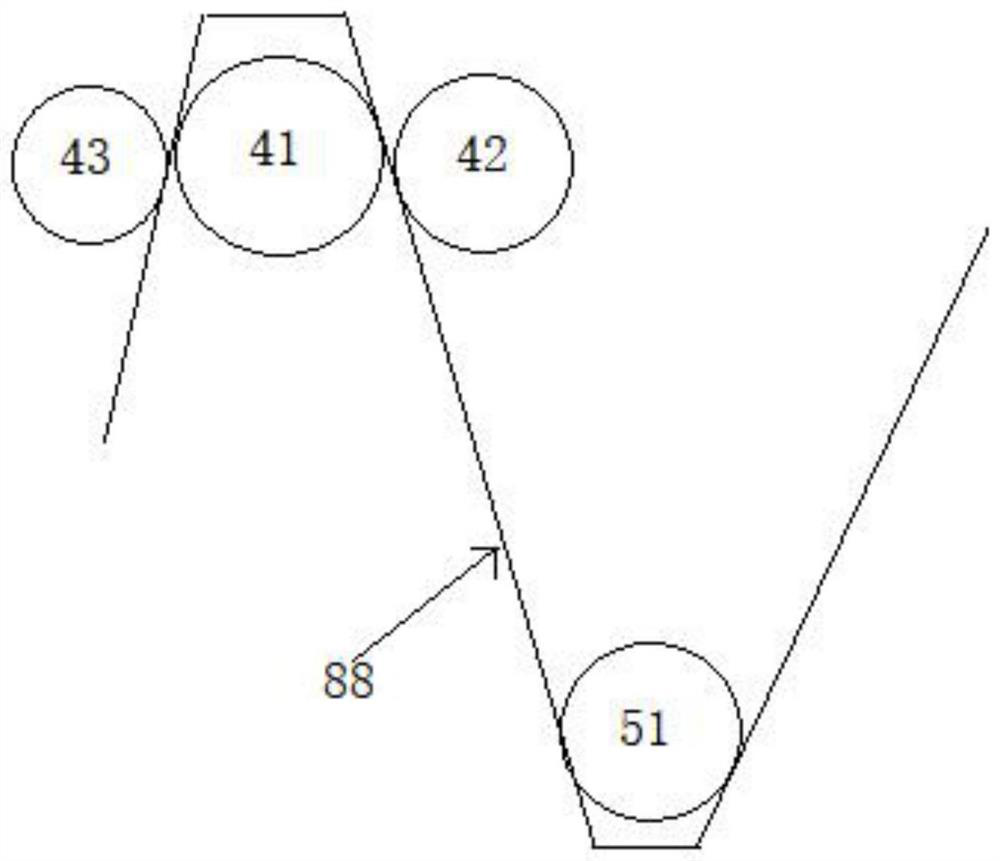

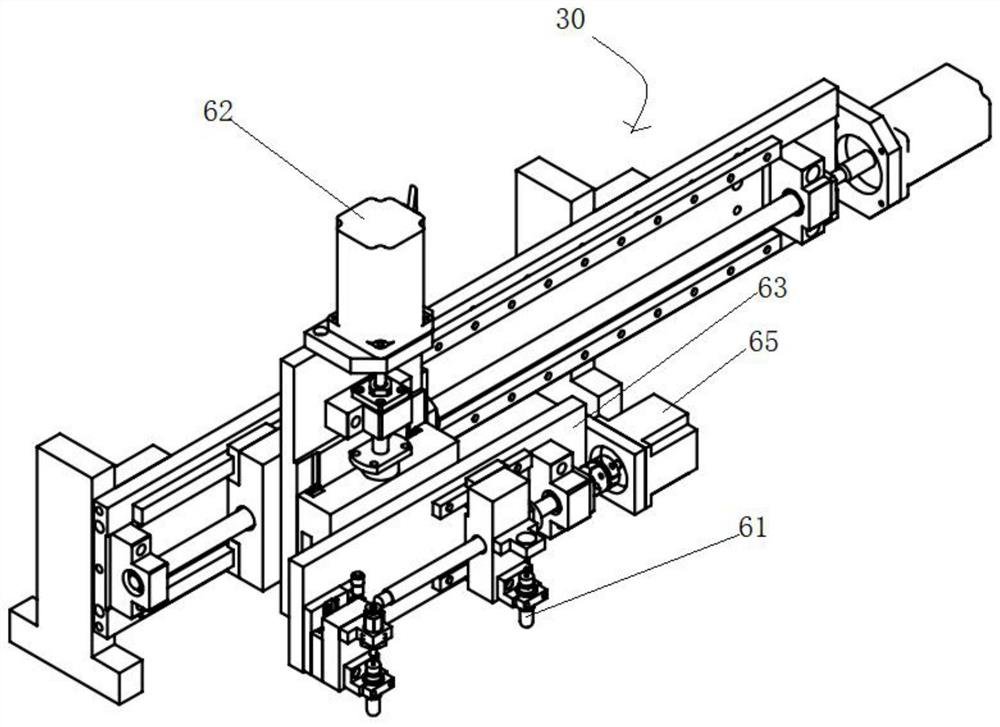

[0024] Such as figure 1 , figure 2 as shown, figure 1 It is the first three-dimensional schematic diagram of the automatic die-cutting mechanism of the present invention; figure 2 It is a connection diagram of the first pressing roller, the second pressing roller, the first driving roller and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com