Stopping agent spraying device for coal seam fire extinguishing

A technology of spraying device and chemical inhibitor, which is applied in the field of coal chemical industry, can solve the problems of waste of resources, labor consumption, and delay in fire extinguishing time, and achieve the effects of reducing work intensity, improving fire extinguishing efficiency, and increasing the selection of types.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

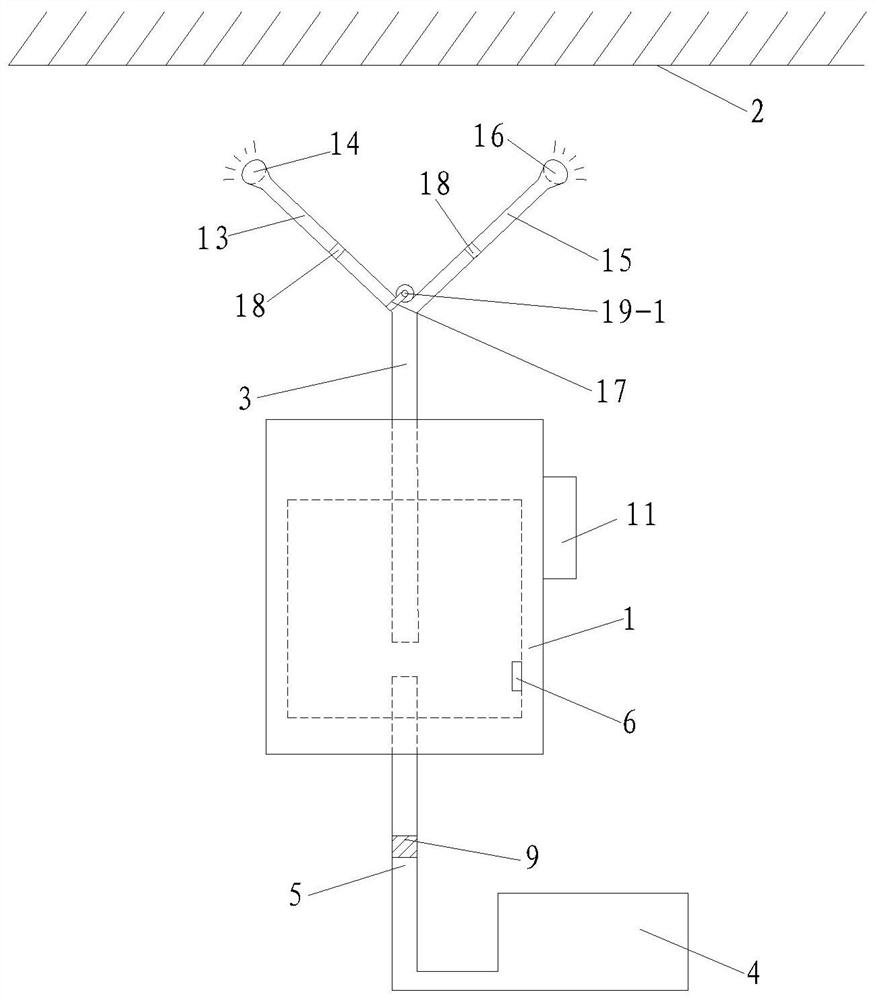

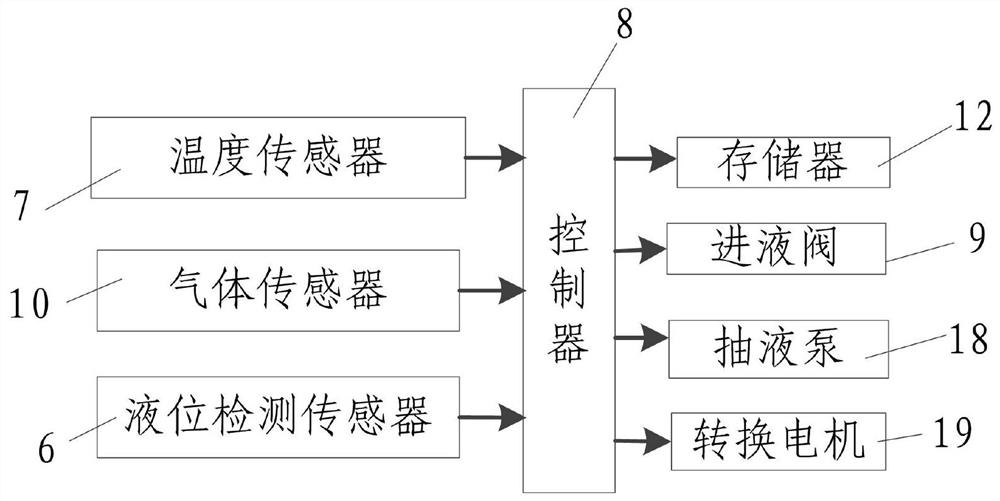

[0031] Such as figure 1 with figure 2 As shown, the present invention includes an inhibitor liquid storage tank 1, a spraying structure that is arranged on the top of the inhibitor liquid storage tank 1 and is used to spray the inhibitor to the coal seam 2, and the inhibitor liquid storage tank The detection mechanism for detecting the box 1 and the coal seam 2; the inhibitor liquid storage tank 1 communicates with the spray structure through the inhibitor liquid outlet pipeline 3;

[0032] The spraying structure includes a liquid spraying mechanism that communicates with the retardant storage tank 1 and is used to spray the liquid retardant to the coal seam 2 and communicates with the retardant storage tank 1 and is used to spray the retardant to the coal seam 2. Coal seam 2 is an atomized spray mechanism for spraying atomized inhibitors; both the liquid spray mechanism and the atomized spray mechanism pass through the inhibitor liquid outlet pipeline 3 and the inhibitor li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com