Wear-resistant anti-deformation building formwork

A construction template and anti-deformation technology, which is applied in the direction of construction, building structure, formwork/formwork components, etc., can solve the problems of uneven application, deformation, and affecting the quality of concrete, so as to increase the direction of reinforcement and improve the fixed anti-deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

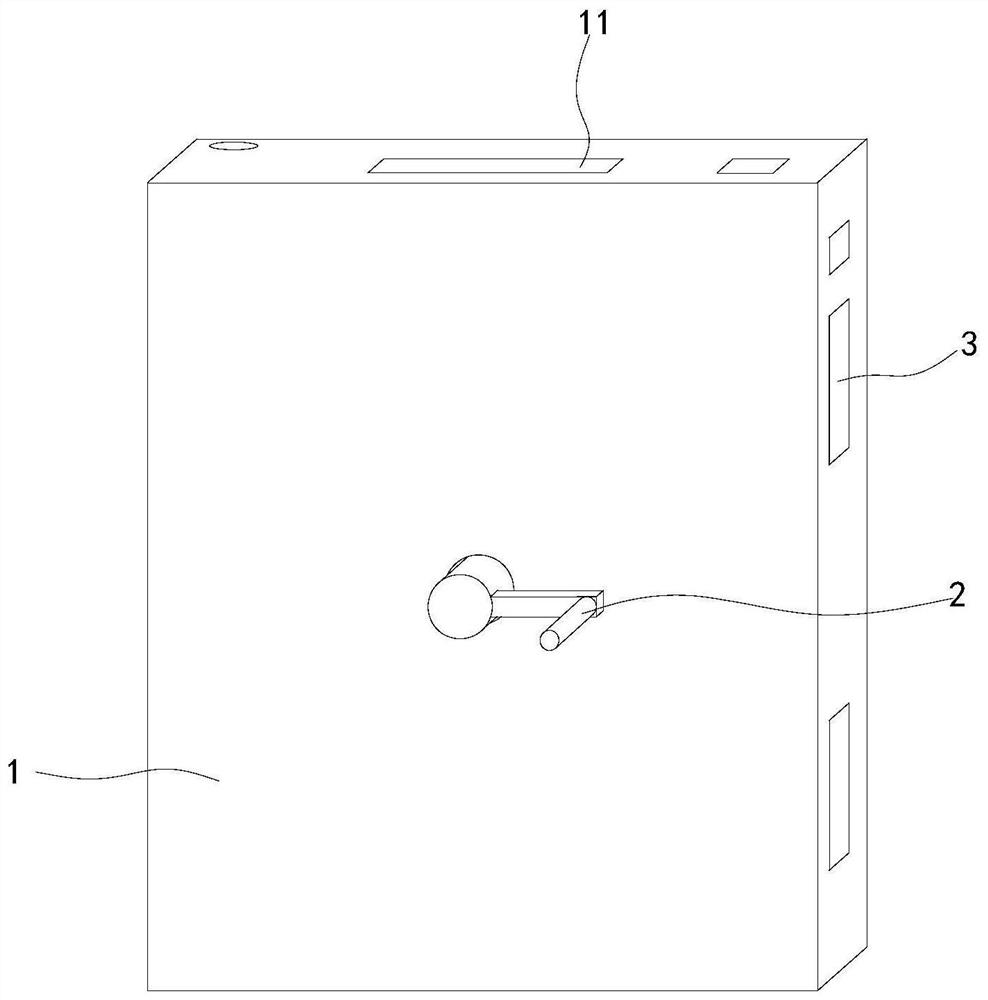

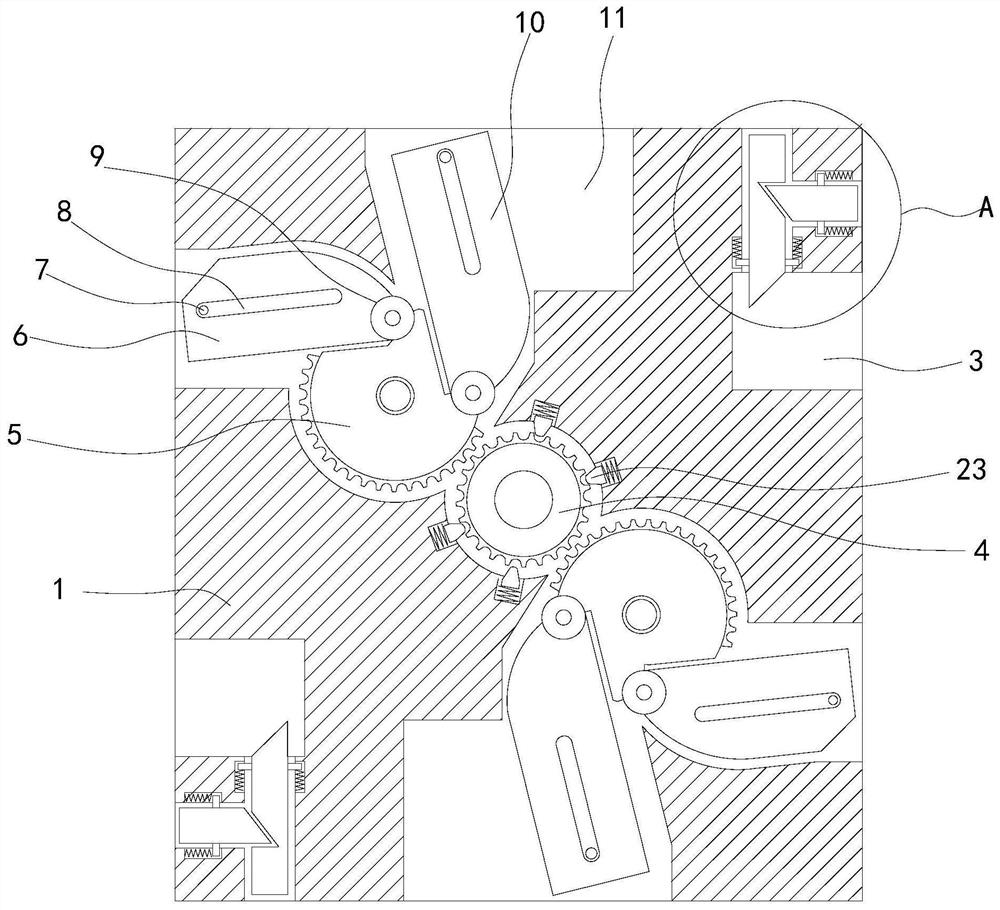

[0029] see Figures 1 to 8 , a schematic diagram of a planar structure and a schematic diagram of a three-dimensional structure of a wear-resistant and anti-deformation building formwork.

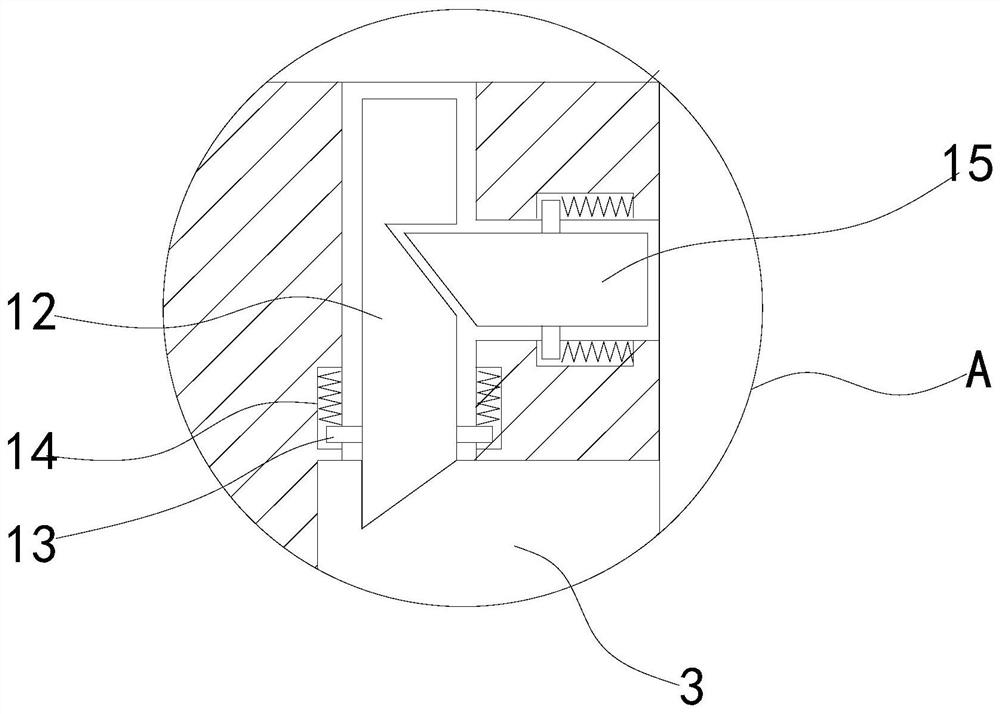

[0030] A wear-resistant and anti-deformation building formwork, comprising a device main body 1, a release agent cavity 17, a rotating handle 2 is movably installed in the center of the front of the device main body 1, a transmission gear 4 is fixedly installed in the center of the device main body 1, and the interior of the device main body 1 is relatively driven. The outer side of the gear 4 is fixedly equipped with a runner 5, the left and right sides of the device main body 1 are provided with a first card slot 3, the inside of the release agent chamber 17 is movable and installed with a trigger block 16, and the upper and lower ends of the device main body 1 are provided with a second card slot 11.

[0031] In a specific implementation, the outer side of the runner 5 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com