Mixing ship for conveying concrete

A technology for mixing ships and concrete, applied in mixing plants, cement mixing devices, clay preparation devices, etc., can solve the problems of low work efficiency, waste of time, increase project cost, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

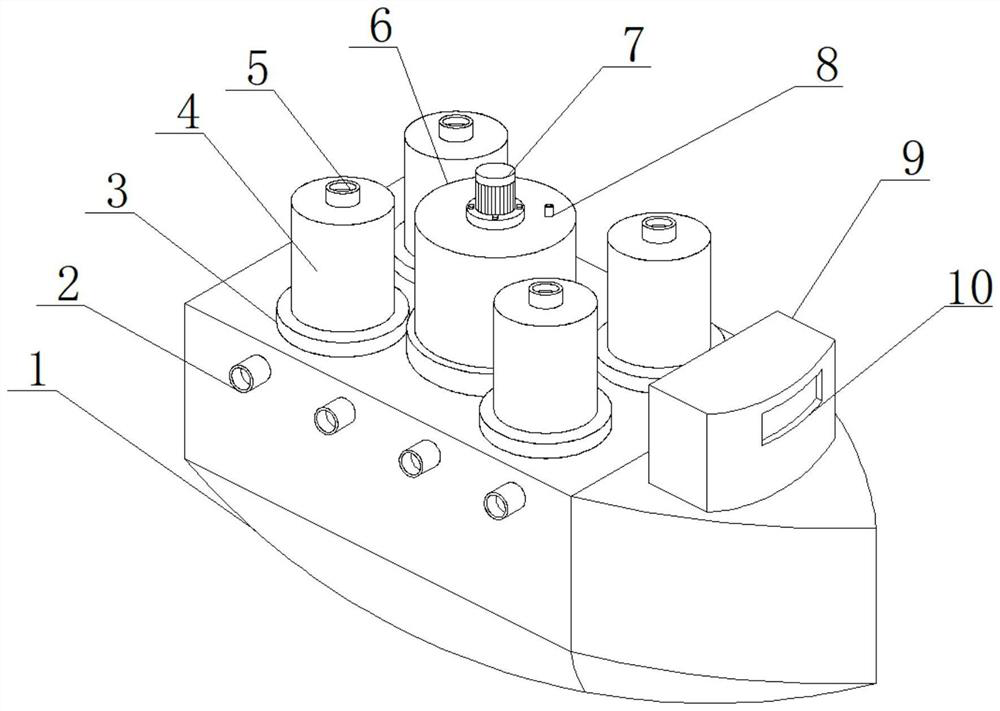

[0027] As a preferred embodiment of the present invention, a control room 9 is installed on the hull 1 , an observation window 10 is installed on the control room 9 , and the control box 24 is installed inside the control room 9 .

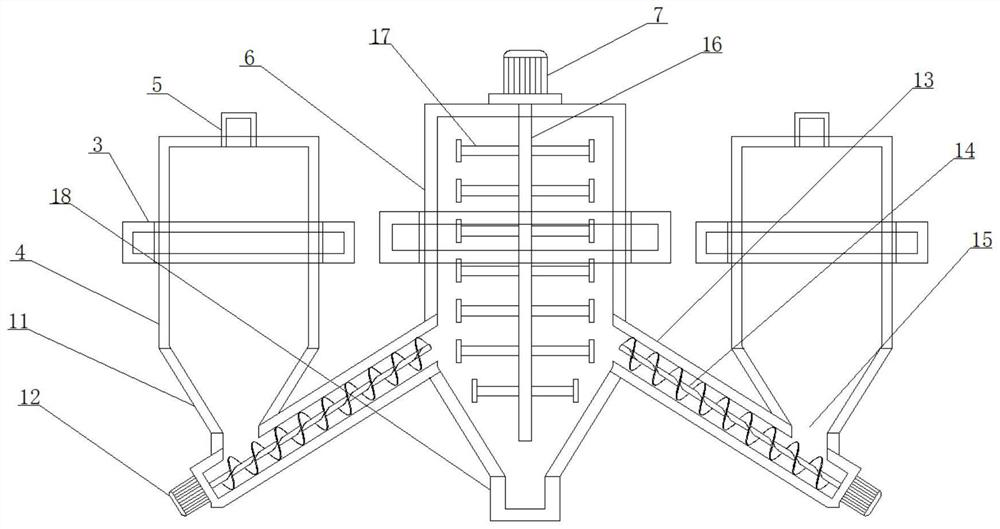

[0028] As a preferred embodiment of the present invention, an output shaft 16 is installed on the first motor 7 , a stirring rod 17 is installed on the output shaft 16 , and a discharge port 18 is installed at the bottom of the mixing bucket 6 .

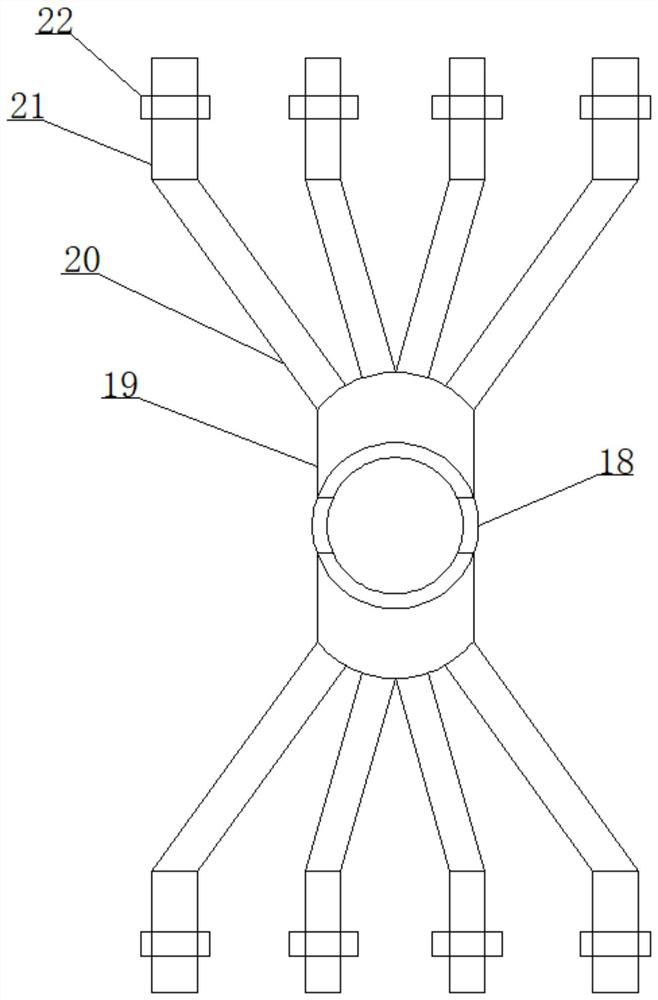

[0029] As a preferred embodiment of the present invention, a mounting portion 19 is fixed on both sides of the discharge opening 18, and a connecting pipe 20 is mounted on one end of the mounting portion 19, and a pipe 21 is welded on the connecting pipe 20, so that The pipeline 21 is connected with the discharge pipe 2, and the control valve 22 is installed on the pipeline 21.

[0030] As a preferred embodiment of the present invention, the humidity sensor 23 is installed inside the mixing bucket 6 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com