Planetary vibration ball mill

A vibrating ball and planetary technology, applied in grain processing, etc., can solve the problems of easy sticking of samples, agglomeration, and inability to grind samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1, such as Figure 1-Figure 2 As shown, the specific structure of this embodiment is: it includes a base 1 with an open upper end, a main motor 2 is arranged in the base 1, the output shaft of the main motor 2 is connected to the rotating shaft 4 at the lower end of the rotating disc 3, and the rotating The driving gear 5 on the shaft 4 meshes with the planetary gear 7 on the planetary shaft 6. The upper end of the planetary shaft 6 passes through the rotating disk 3 and is connected to the grinding tank seat 8. The connection between the planetary shaft 6 and the rotating disk 3 is provided with a bearing , the ball milling pot 9 is placed in the grinding pot seat 8; the auxiliary motor 10 is arranged in the base 1, the output shaft of the auxiliary motor 10 is connected with the driving shaft 11, and the driving shaft 11 is non-horizontally arranged. In the embodiment, the drive shaft 11 is arranged vertically; the main motor 2 is placed on the upper end of th...

Embodiment 2

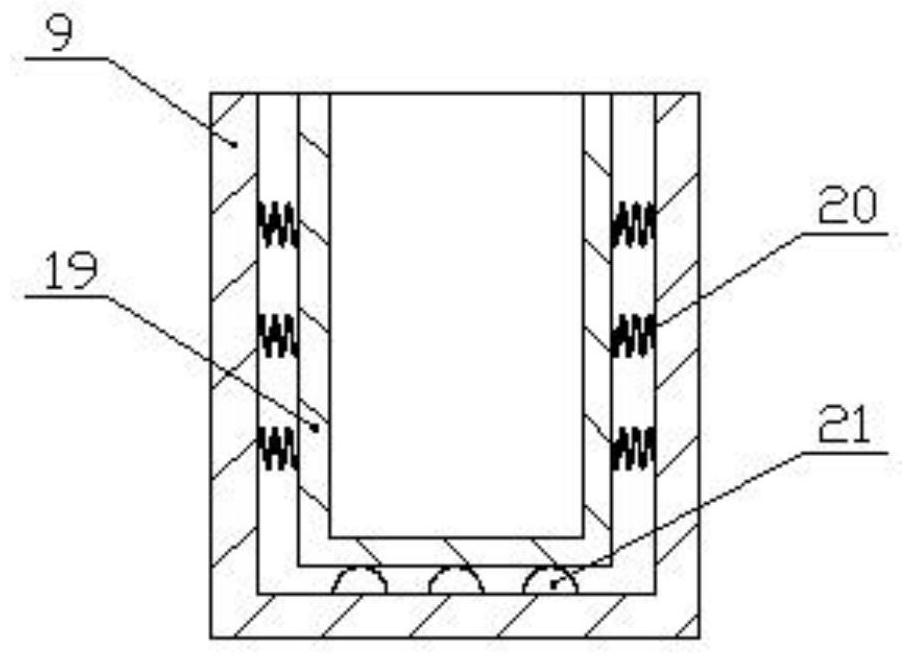

[0022] Example 2, such as Figure 1-Figure 2 As shown, the other structures of this embodiment are the same as those of Embodiment 1, but in this example, an inner tank 19 is provided on the inner sleeve of the ball milling tank 9, and a Swing spring 20; the inner bottom wall array of the ball mill tank 9 is provided with a rubber pad 21, and the upper end of the rubber pad 21 is in contact with the inner tank 19.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com