Prefabricated hollow pile pipe valve-type pile shoe and construction method thereof

A technology of hollow pile and valve type, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of wasting time, manpower and material resources, and achieve the effect of increasing the bearing area, reducing resistance and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

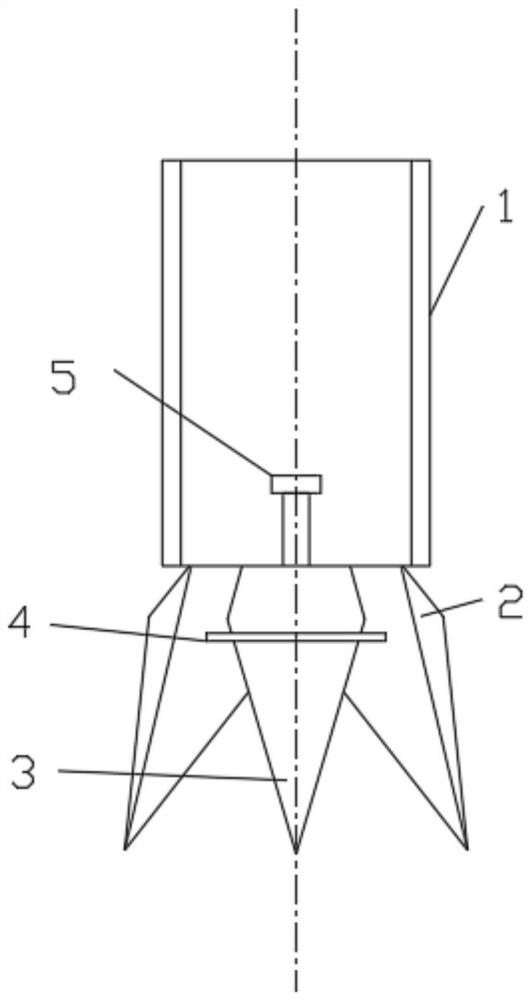

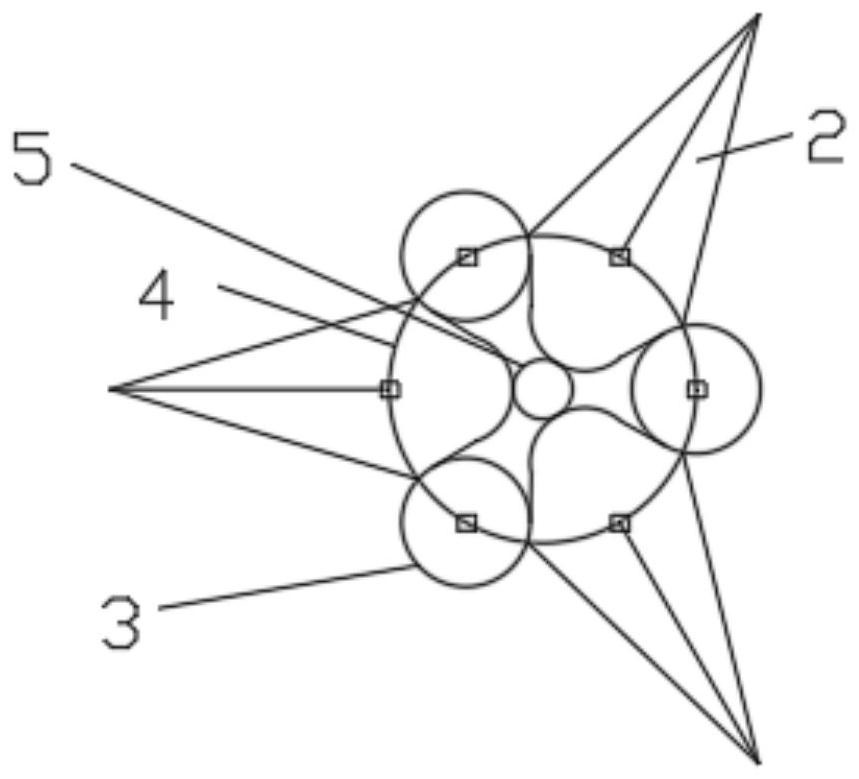

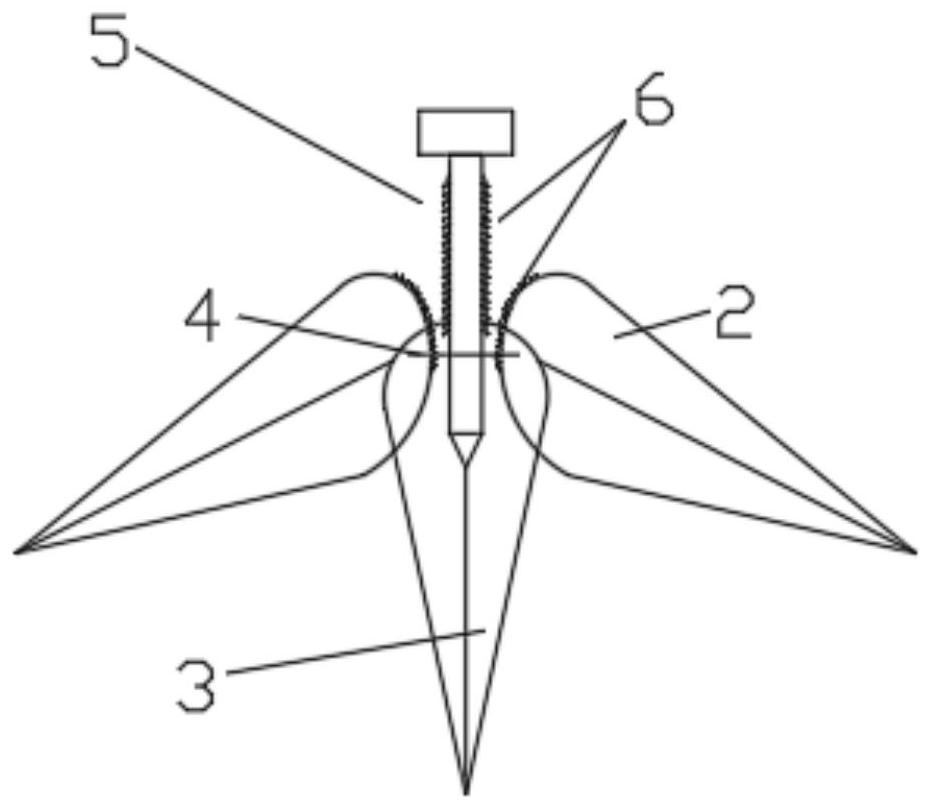

[0037] Embodiment: a kind of prefabricated hollow pile pipe valve type spud can, such as Figure 1-Figure 3 As shown, it includes a hollow pile tube 1 and a valve assembly, and the valve assembly is located at the lower end of the hollow pile tube;

[0038] The valve assembly includes a plurality of valves 2, a plurality of fixed valves 3, a connecting ring 4 and a wedge-shaped plug 5, and a plurality of the fixed valves and a plurality of the valves are all pierced through the connecting ring, the The end of the fixed valve close to the connecting ring is fixedly connected with the hollow pile tube, and the valve can rotate relative to the hollow pile tube;

[0039] When the fixed valve and the valve are in a natural drooping state, a tapered structure is formed;

[0040] When the wedge-shaped plug moves downward under the action of external force, all the valves rotate outward, the end of the fixed valve close to the connecting ring, the end of the valve close to the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com