An accurate weighing loading robot arm and loading method

A robotic arm, precise technology, applied in weighing, measuring devices, loading/unloading, etc., can solve problems such as reducing loading efficiency, and achieve the effect of improving loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

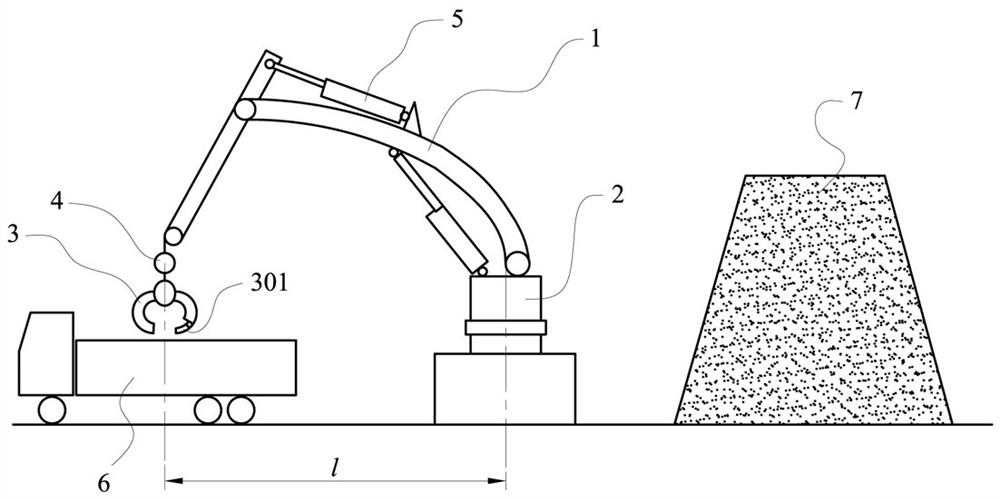

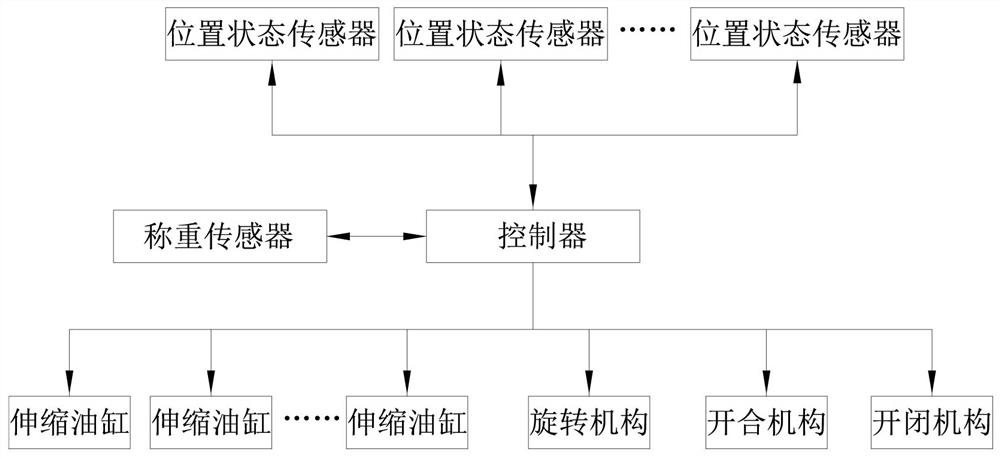

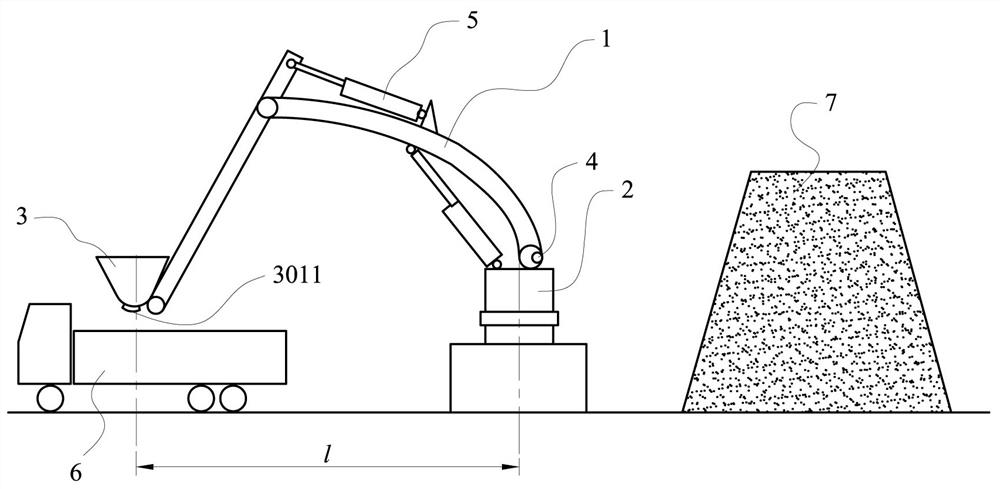

[0026] This embodiment is an accurate weighing loading robot arm, such as figure 1 , 2 shown. This embodiment includes: at least two hinged arm segments 1 ( figure 1 Shown as two arm sections in the figure), one end of the arm section is hingedly connected with the rotating platform 2 and a position state sensor is installed, and the other end of the arm section is hingedly connected with the hopper 3 and a position state sensor is installed. The load cell 4, the hopper is provided with a fine-tuning gate 301; the telescopic oil cylinder 5 of each arm segment, the rotating mechanism of the rotating platform, the opening and closing mechanism of the hopper, the opening and closing mechanism of the fine-tuning gate, as well as various position state sensors, weighing The sensor is electrically connected to the controller.

[0027] The basic principle of this embodiment is as follows: the loading manipulator is set between the material pile 6 and the transporting machine 7, an...

Embodiment 2

[0035] This embodiment is an improvement of the above-mentioned embodiment, and is a refinement of the above-mentioned embodiment about the rotating platform. The rotating platform described in this embodiment is either fixedly connected to the ground or installed on the traveling mechanism.

[0036] The rotating platform can be fixed. For example, in the application places such as ports and coal storage yards, the position of the material transportation equipment is relatively fixed. The rotating platform can be fixed on the reinforced concrete foundation with bottom corner bolts.

[0037] The running gear can be a vehicle chassis of various forms, such as a wheeled vehicle chassis with or without a track, or a tracked chassis. The vehicle chassis may be powered, such as an internal combustion engine or an electric motor, or unpowered, with motion produced by a winch or other vehicle traction.

Embodiment 3

[0039] This embodiment is an improvement of the above-mentioned embodiment, and is a refinement of the above-mentioned embodiment on the traveling mechanism. The traveling mechanism described in this embodiment is a self-powered wheeled or crawler-type traveling chassis or a non-powered wheeled trailer.

[0040] The self-powered wheeled or crawler walking chassis can be an automobile or crawler tractor driven by a motor or an internal combustion engine, and is equipped with corresponding counterweights and balance supports.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com