Climbing robot for angle steel tower

A technology of angle steel towers and robots, which is applied in the direction of manipulators, motor vehicles, manufacturing tools, etc. It can solve problems such as tilting conditions and doubtful reliability of rear mechanical claws, and achieve stable and stable clamping, high climbing efficiency, and guaranteed movement stability. and action reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] For the convenience of overall understanding, the structure and working method of the specific embodiment of the climbing robot for the whole angle steel tower are described as follows:

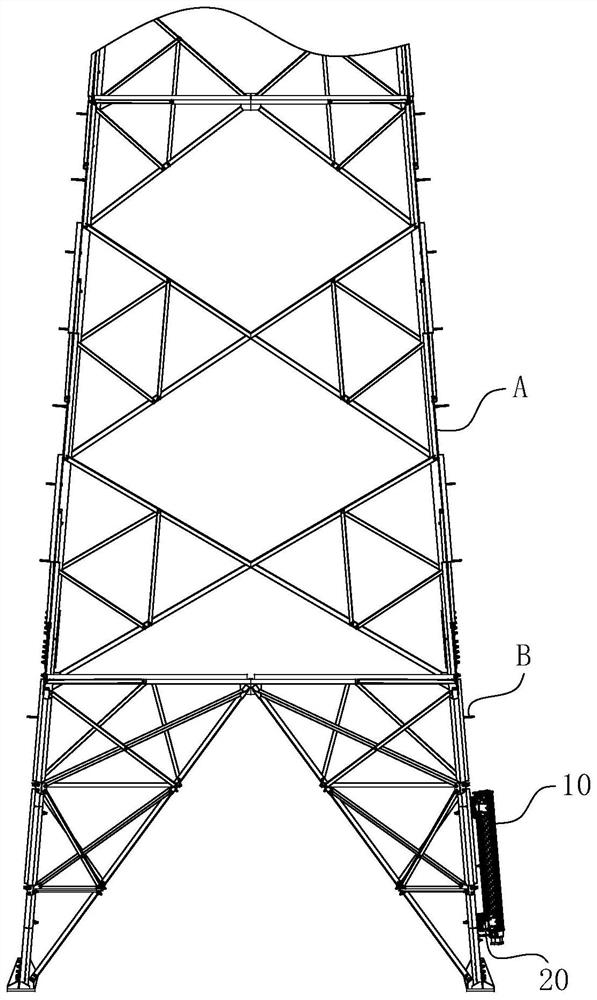

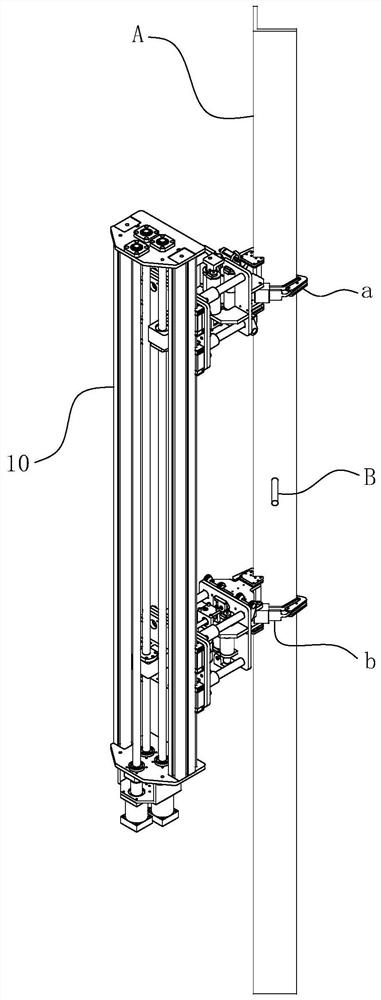

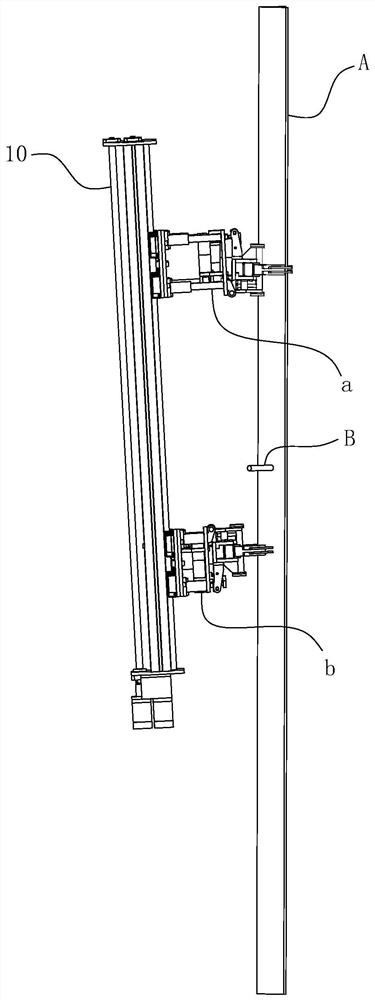

[0058] Climbing robot for angle steel tower, such as Figure 1-20 As shown, its main structure includes a strip-shaped frame-shaped host 10 and clamping components arranged on the host 10; in actual operation, the length direction of the host 10 should be parallel to the length direction of the angle steel A. A sliding track is arranged on the side of the host 10 facing the angle steel A, and an electronically controlled sliding block is arranged on the sliding track, so that the reciprocating motion can be generated in the length direction of the host 10 according to the action of the control unit; Secure a set of clamping components. exist Figure 1-6 In the structure of the specific embodiment shown, it can be seen that the clamping components are divided into two groups, that is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com