Automatic device for wave-shifted optical fiber bending

An automatic device and bending device technology, which is applied to optical components, other household appliances, household appliances, etc., can solve the problems of affecting signal transmission, waste of wave-shifting optical fibers, and difficulty in ensuring the consistency of optical fiber bending in water baths, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

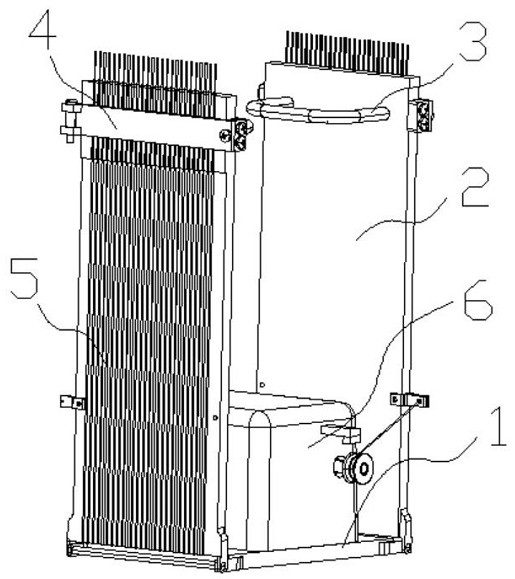

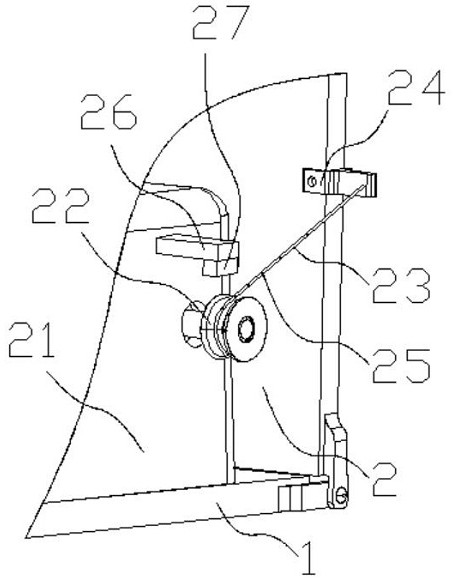

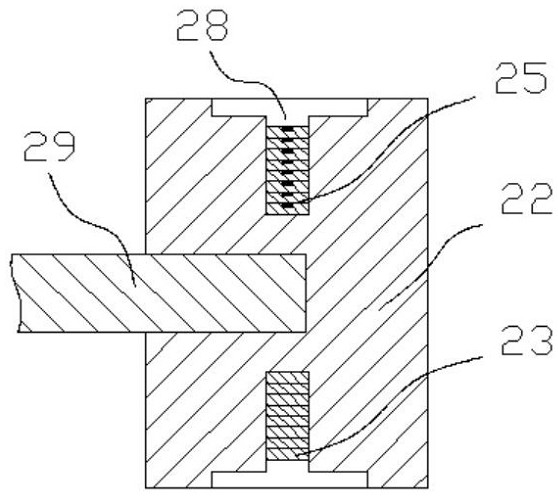

[0018] Such as Figure 1-Figure 2 As shown, the structure of the present invention is: an automatic device for bending wave-shifting optical fibers, including a flat plate 1, the two ends of the flat plate 1 are hinged with a bending plate 2 that can only rotate 90 degrees, and the flat plate 1 The first fiber groove group matched with the wave-shifting optical fiber 5 is arranged side by side, and the bending handle 3 is arranged on one side of the bending plate 2, and the pressing device 4 matched with the wave-shifting optical fiber 5 is arranged on the other side, A bending device 6 is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com