Chuck mechanism convenient to adjust

A chuck and chuck cover technology, which is used in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of inconvenient operation, low accuracy, and inability to form highly automated processing, reducing the Production cost, the effect of large adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

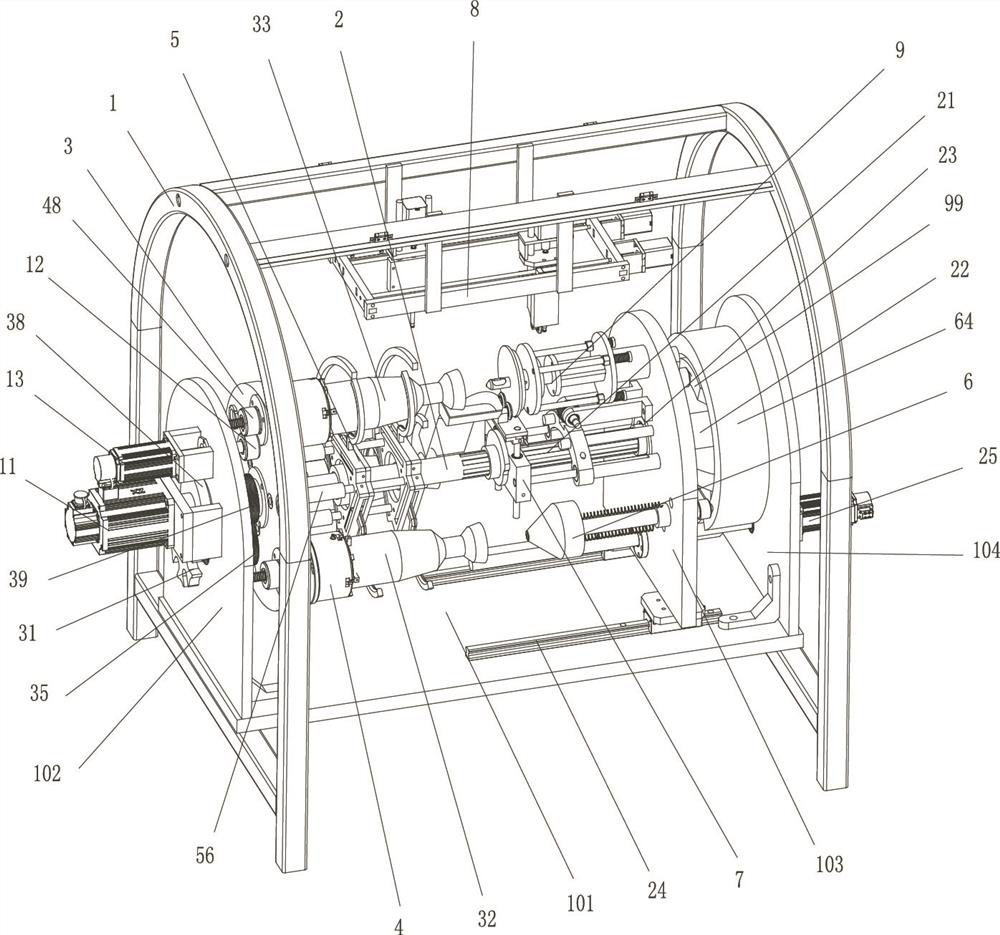

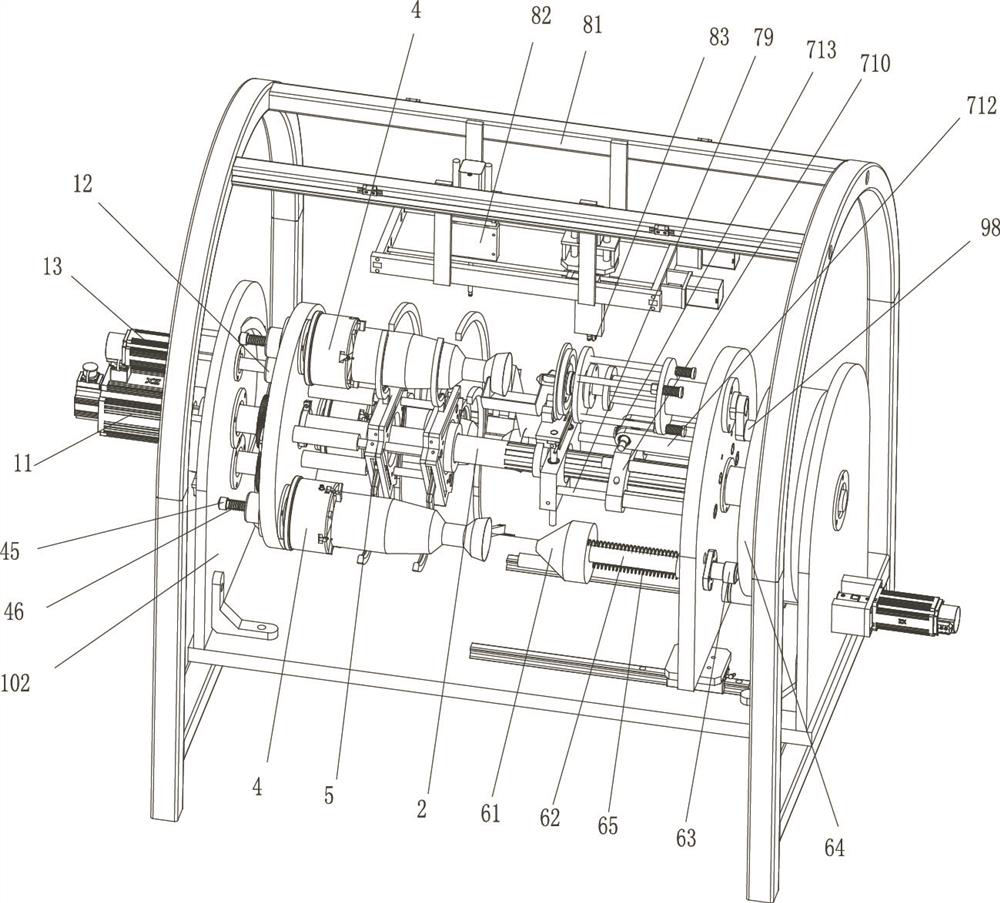

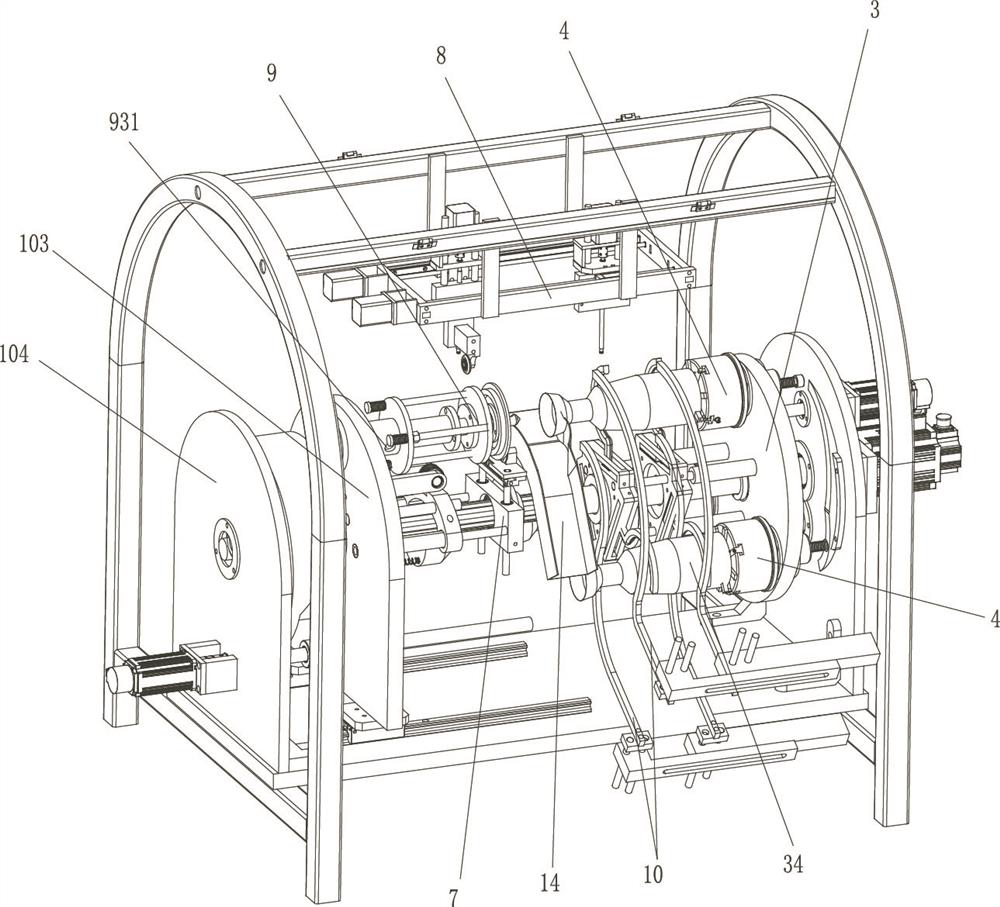

[0039] refer to Figure 1-12 As shown, it is a specific embodiment of the present invention: a high-efficiency thermos cup head cutting machine and an easy-to-adjust chuck mechanism for the head cutting machine. The whole machine includes:

[0040] A frame 1 , the frame includes a bottom plate 101 , a first vertical plate 102 , a second vertical plate 103 , and a third vertical plate 104 .

[0041] The main shaft 2, the main shaft 2 is arranged horizontally, runs through the first vertical board 102, the second vertical board 103, and the third vertical board 104, and is connected with each vertical board through bearings. The main shaft 2 is driven by the first motor 11, and the main shaft 2 keeps rotating during operation.

[0042] The turntable 3 is sheathed on the main shaft 2 and is linked with the main shaft 2 through a set of sheave mechanisms 31 . The turntable 3 includes a loading station 32, a processing station 33 and a blanking station 34, and the rotation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com