A mobile cutting machine

A cutting machine, mobile technology, applied in the direction of hand-held metal shearing equipment, shearing devices, manufacturing tools, etc., can solve the problem of affecting cutting speed and cutting quality, difficult to fully observe and operate, difficult to cut position alignment, etc. Problems, to achieve the effect of easy cutting operation, convenient observation and positioning, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with embodiment the present invention is described in further detail:

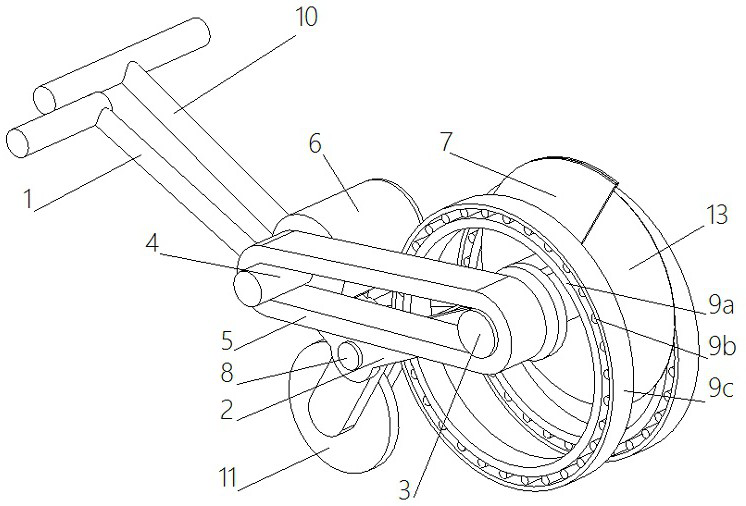

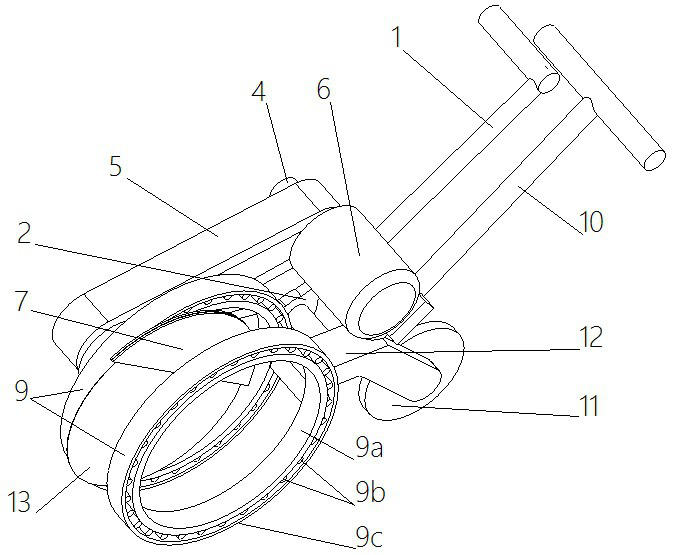

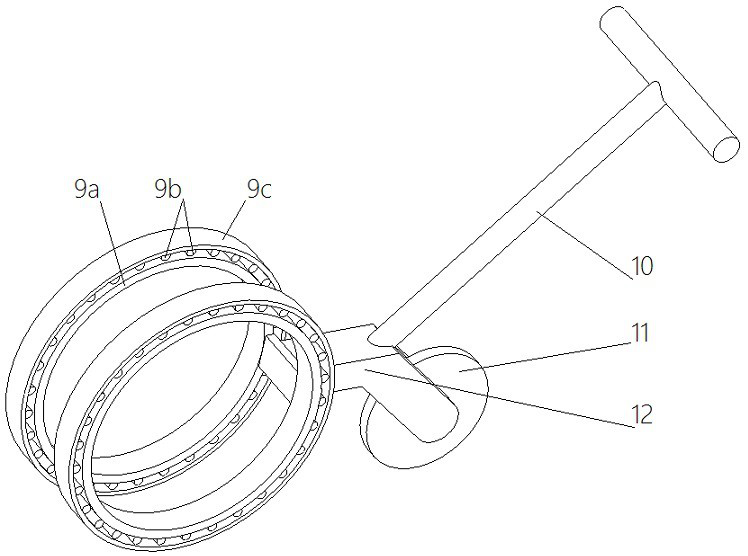

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, a kind of movable cutting machine comprises frame 2, cutter shaft 3, motor pulley 4, belt 5, motor 6 fixed on the frame 2, cutting blade 13, sleeved on the outside of cutting blade 13 Shield 7 also comprises traveling vehicle, and all devices of original cutting machine are all arranged on the traveling vehicle. Walking cart comprises vehicle frame 12, hubless wheel 9, cart handle 10, walking wheel 11, and hubless wheel 9 is symmetrically arranged on vehicle frame 12 front ends, and hubless wheel 9 is hollow setting, and hubless wheel 9 is provided with two. The cart handle 10 is fixedly connected on the vehicle frame 12, and the traveling wheels 11 are hinged at the rear of the vehicle frame 12; the frame 2 is also provided with a frame hinge point 8 and a cutting machine handle 1, and the frame hinge point 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com