Square pipe joint necking machine

A technology of square tube and necking, which is applied in the direction of chemical instruments and methods, cleaning methods and utensils, and removal of smoke and dust, and can solve the problems of surface scratches, accumulation, iron filings adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] as attached figure 1 to attach Image 6 Shown:

[0029] The invention provides a square pipe joint necking machine, which is structured with a body 1, a control door 2, a motor 3, an adjustment table 4, a press frame 5, a necking device 6, and a rear drive table 7. The control door 2 is installed On the front end surface of the body 1, the motor 3 is installed on the side end of the body 1, the adjustment table 4 is installed and connected above the body 1, and the press frame 5 is fixedly arranged on the top surface of the body 1 , the necking device 6 is located at the side end position of the press frame 5 and is movably matched, the rear drive table 7 is fixedly installed on the top surface of the body 1, and the rear drive table 7 is movably matched with the necking device 6 .

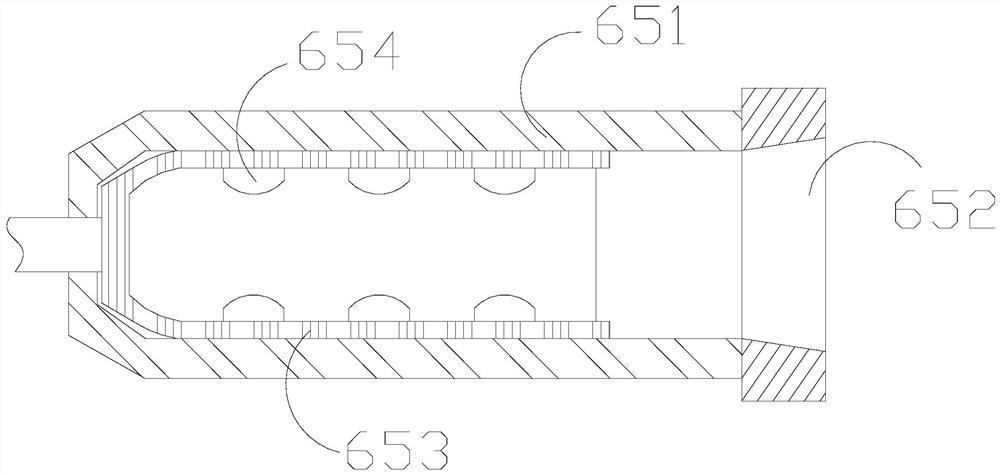

[0030] The necking device 6 is provided with a bottom sliding table 61, a moving block 62, a front clamping block 63, a rear injection end 64, and a necking body 65. The lower end of the ...

Embodiment 2

[0036] as attached Figure 7 to attach Figure 8 Shown:

[0037] Wherein, the arc body 433 is provided with a support end 331, a chip collection device 332, and a contact port 333, the support end 331 is located at the two sides of the arc body 433, and the chip collection device 332 is embedded in the arc body 433 Inside, the contact opening 333 and the arc body 433 are an integrated structure and are arranged on the front end surface of the arc body 433, the chip collection device 332 is provided with three in each of the arc bodies 433, and the support The end 331 is a resin side end, which has a certain hardness supporting effect.

[0038] Wherein, the chip collection device 332 is provided with a one-way door 321, a soft joint section 322, a hard joint section 323, an inner tank chamber 324, a middle clamping plate 325, and a bottom adhesive strip 326. One end of the soft joint section 322 is connected to the single Connected to the door 321 and movably matched, the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com