Connecting element for electrical contact with corresponding contact element of electrical storage unit

A technology for connecting elements and contact elements, applied in electrical components, conductive connections, battery pack components, etc., can solve problems such as damage and high installation force, and achieve the effect of reducing spring stiffness, reducing installation force, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

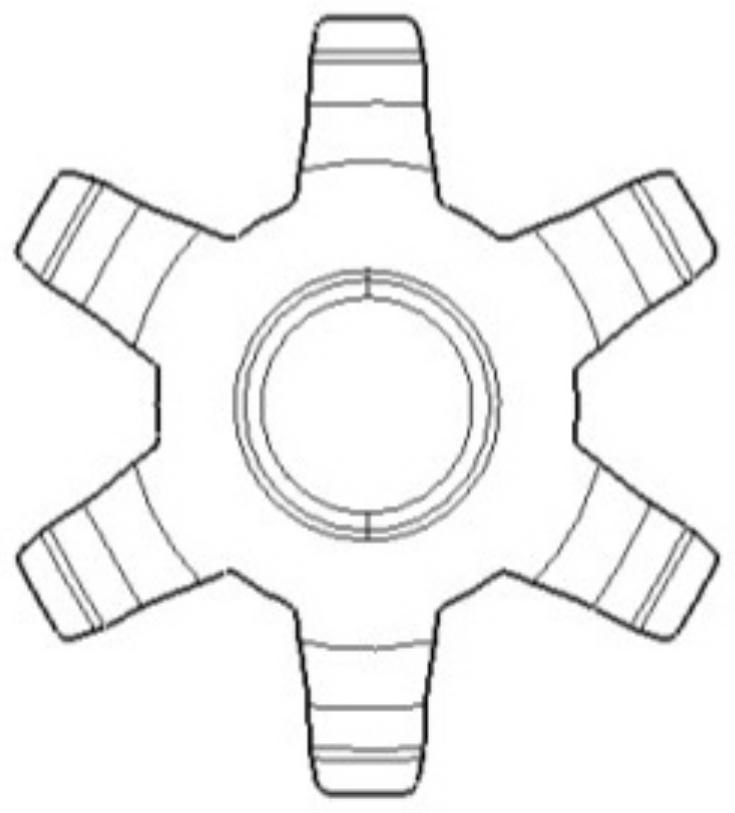

[0036] In the figures, identical or functionally identical elements are provided with the same reference signs.

[0037] Figure 1a Shows a top view of a conventional crown as connecting element according to the prior art with six contact lugs arranged in a star shape with the same height and contact surfaces at the same height . It can be seen that the contact lugs have not yet been bent, but according to Figure 1a The contact lugs already have corresponding curved curved edges. The contact lugs are arranged equidistantly on the contact base and have the same rectangular shape and the same length. For many applications, such as in battery modules of vehicles, these shapes of the crowns are used in combination with corresponding contact elements as electrical and mechanical connection elements.

[0038] Figure 1b Discloses a side view of a conventional crown as connecting element according to the prior art with six curved contact lugs arranged equidistantly in a star shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com