A high-load-bearing metal-rubber composite vibration isolator with three-way stiffness and damping decoupling

A technology combining vibration isolators and metal rubbers, applied in the design characteristics of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of difficult independent adjustment, mutual coupling of stiffness and damping parameters, etc. Adjust difficulty, reduce compressive loads, prevent damage and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

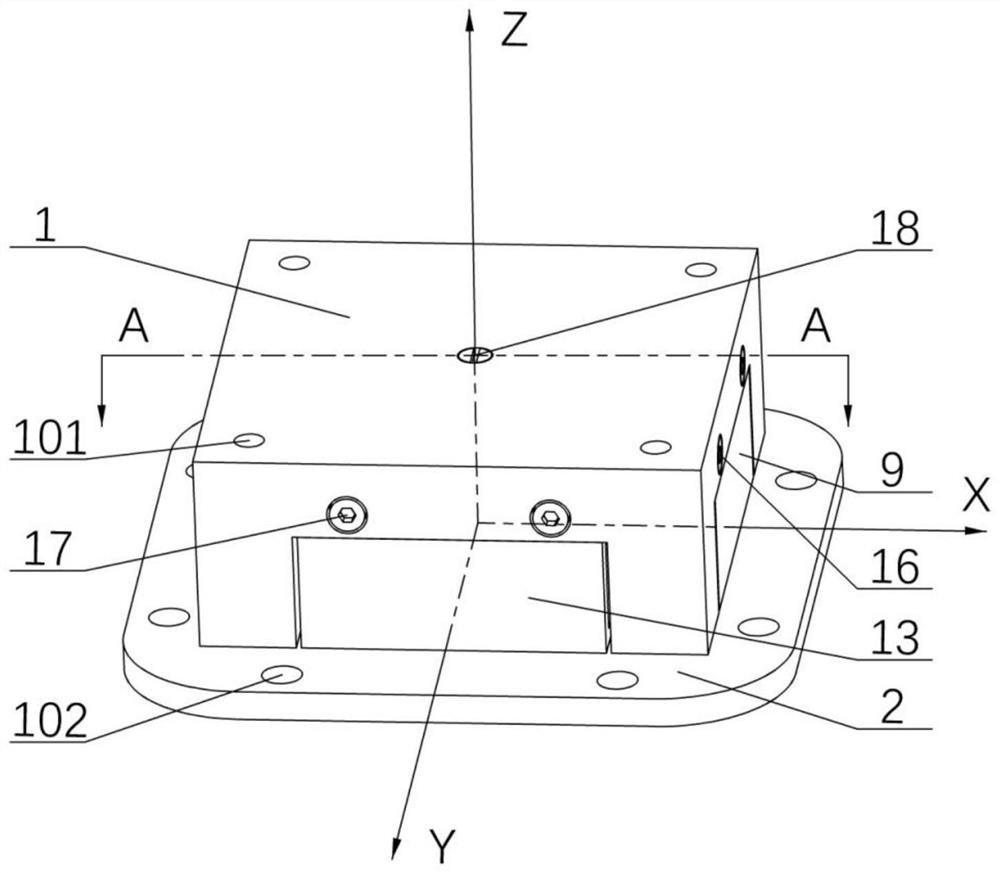

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

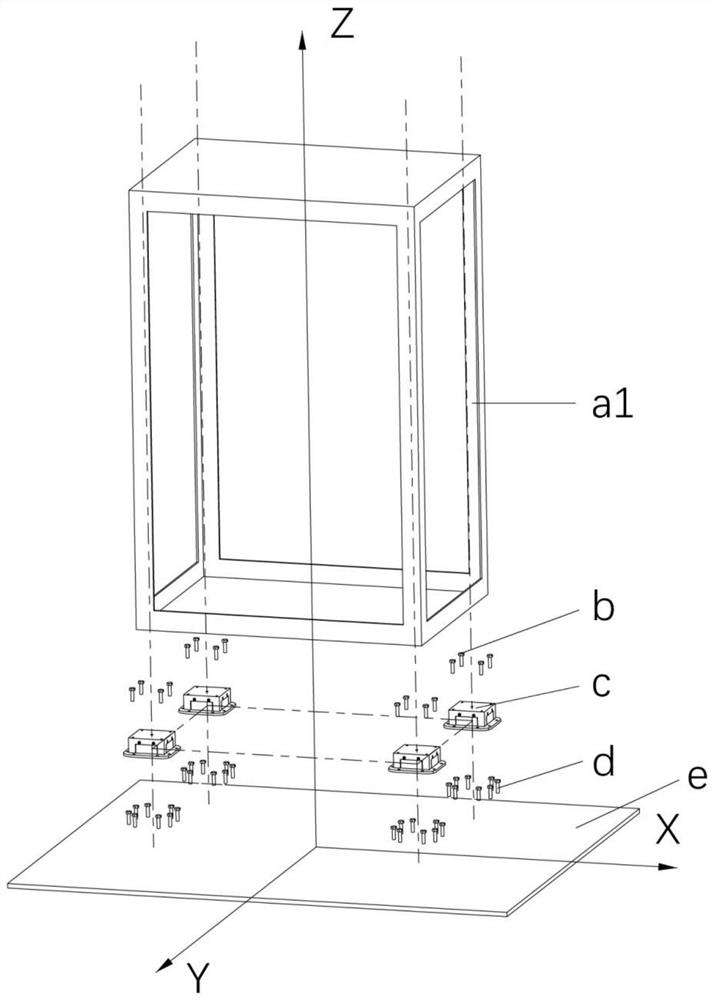

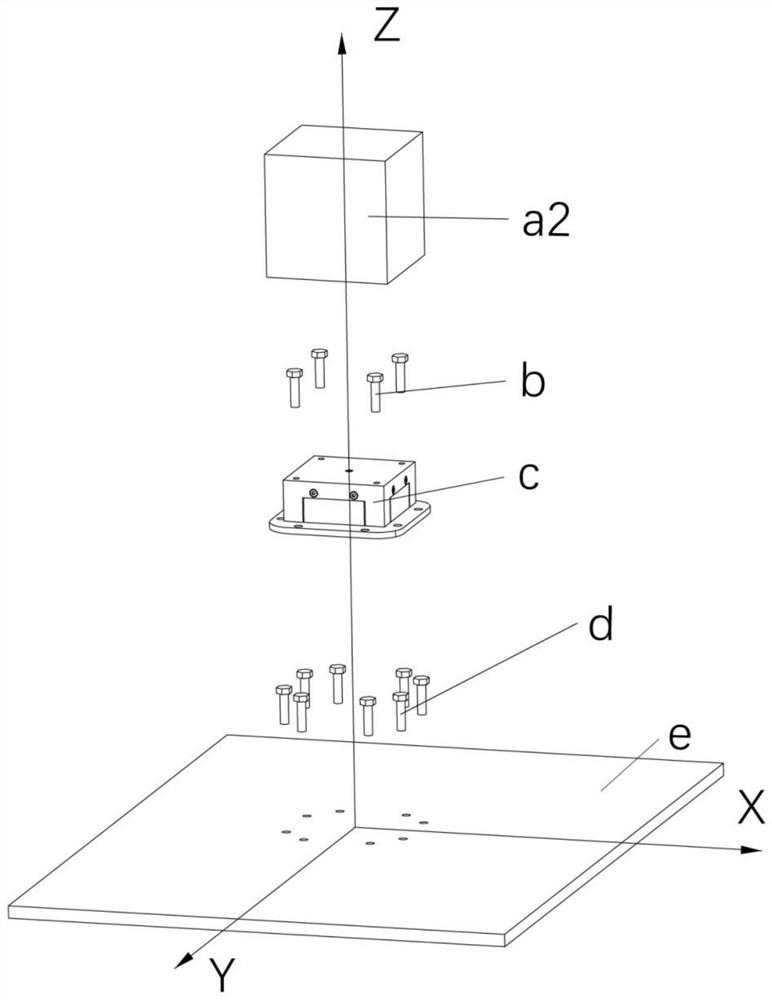

[0047] like figure 1 , figure 2As shown, a three-way stiffness-damping decoupled high-load metal-rubber composite vibration isolator c according to an embodiment of the present invention is installed on the vibration-isolated equipment and the installation infrastructure e. If the vibration-isolated equipment is the airborne equipment cabinet a1, then four vibration isolators c of the present invention are respectively installed to the four corners of the airborne equipment cabinet a1 through 4 groups of first connecting screws b, and then through 4 groups of second connecting screws d Connected to the installation infrastructure e. If the vibration-isolated device is a single airborne instrument a2, a vibration isolator of the present invention is installed on the bottom of the airborne instrument a2 through a set of first connecting screws b, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com