A high-precision and convenient unitized glass curtain wall device and its construction method

A glass curtain wall and unitized technology, applied to walls, buildings, building components, etc., can solve the problems of glass curtain wall installation misalignment, affecting efficiency, and construction errors of embedded parts, so as to improve safety and reliability, and improve construction fault tolerance efficiency and increase the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

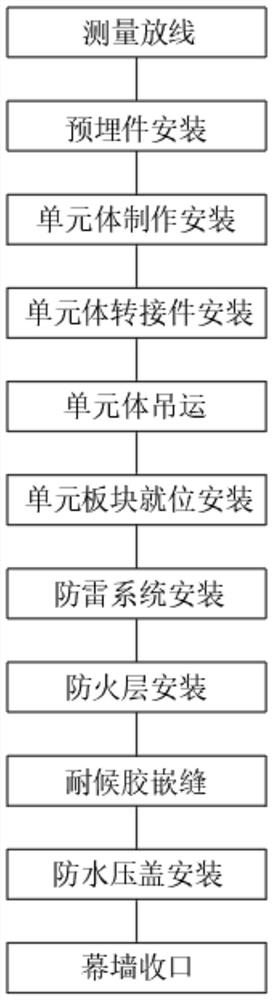

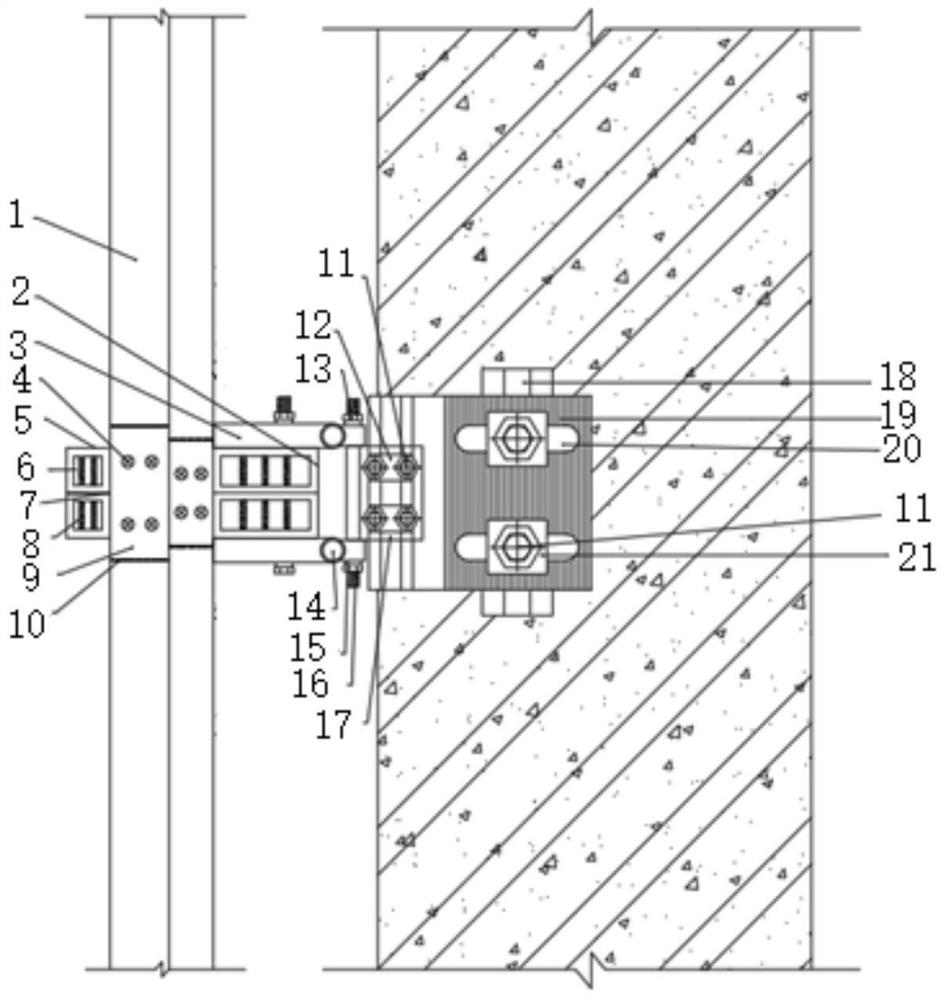

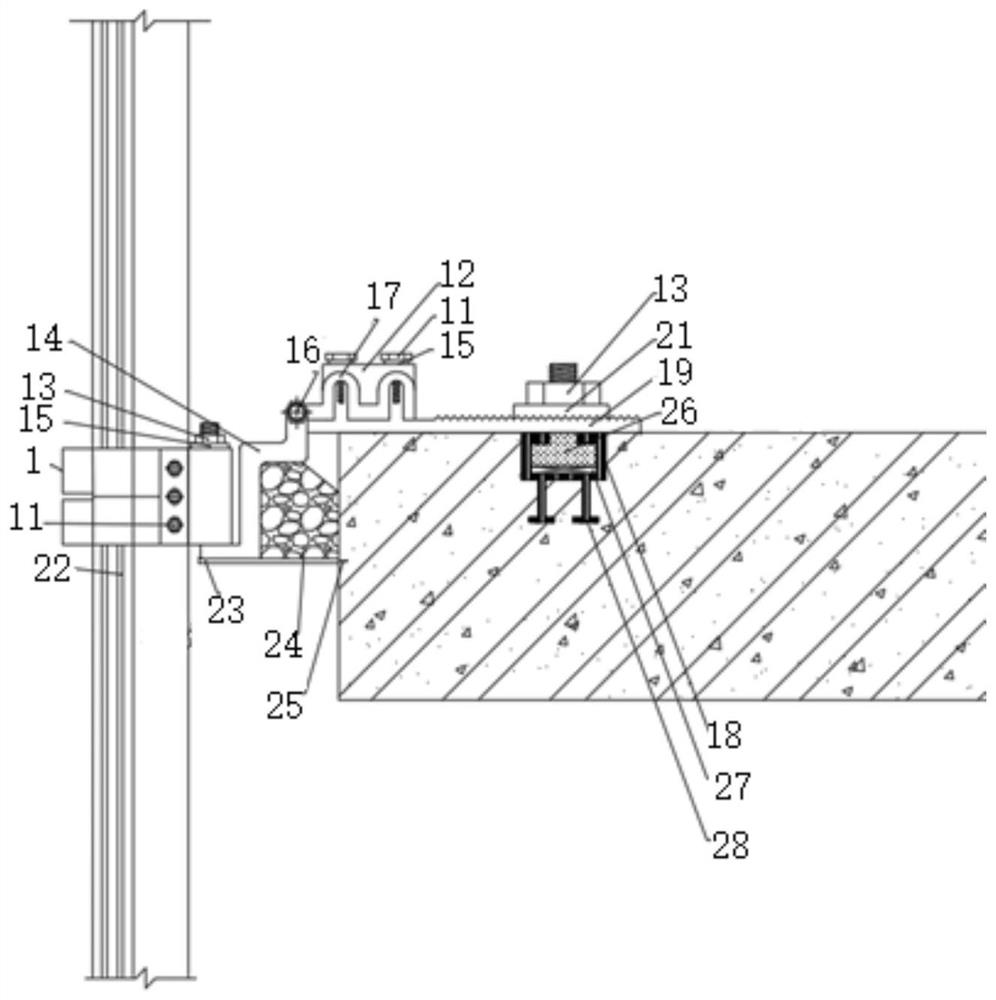

[0050] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as Figure 1-4 As shown, a high-precision and convenient unitized glass curtain wall device is characterized in that: it includes embedded parts embedded in the main body of the building, a unit body for the glass curtain wall, and a unit connected between the embedded parts and the unit body The supporting structure and the double-layer hollow glass arranged in the frame of the unit body, the embedded part is a C-shaped alveolar embedded part 18, and there are two rows of T-shaped feet 28 below it, which are connected with steel bars and act as a fixed pre-embedded part. The function of the embedded part, the inner side of the notch is alveolar, and the inner notch of the C-shaped alveolar embedded part is connected to the T-shaped alveolar screw 26, and the part of the screw connected to the notch of the embedded part is a toot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com