A three-finger dexterous end effector in the palm of a three-motor-driven tandem mechanism

A technology of end effectors and series mechanisms, applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve the problems of non-coincidence of references, difficulty, and large eccentric torque of manipulators, etc., and achieve good versatility and synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

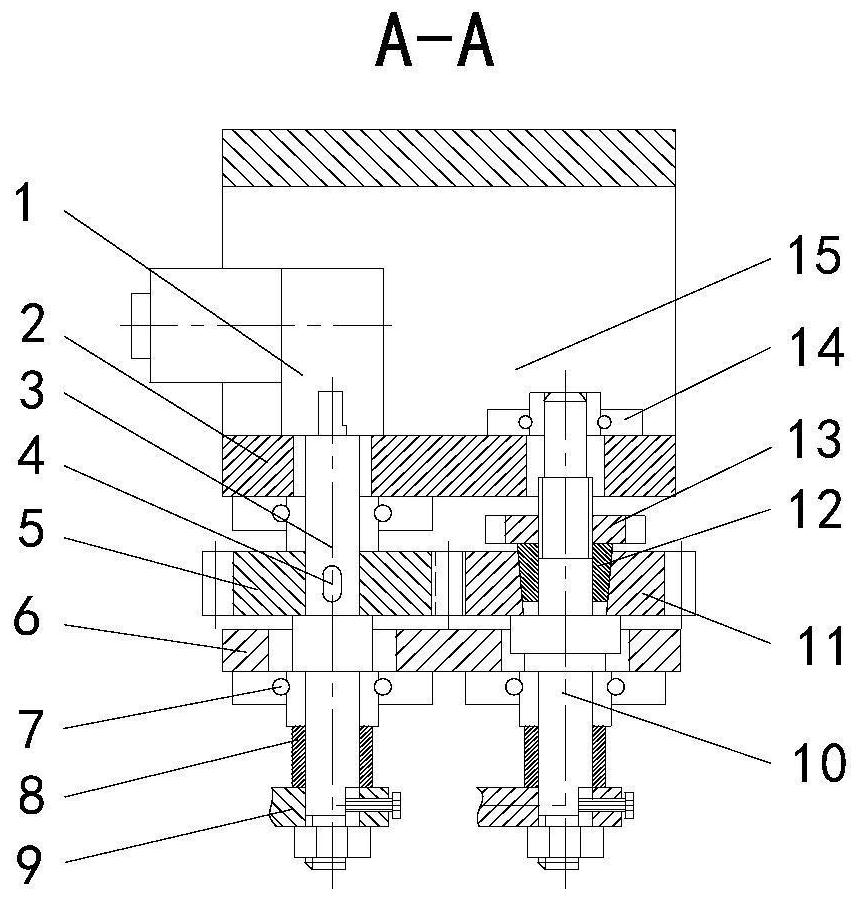

[0041] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

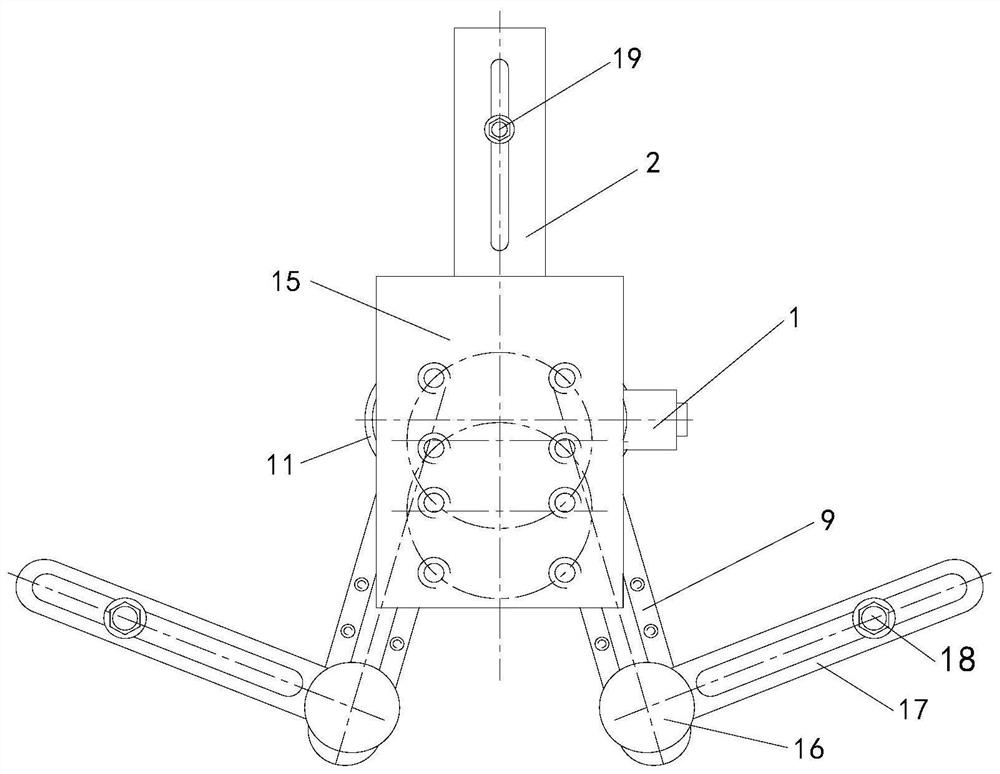

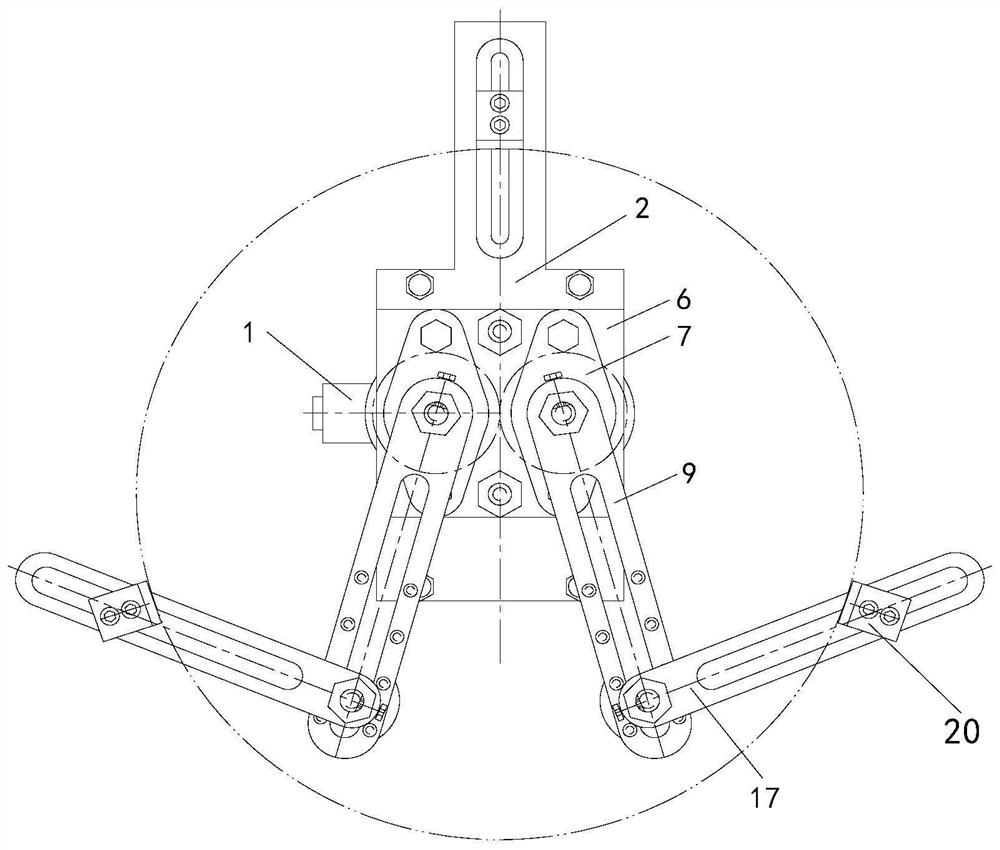

[0042] Such as Figure 1-19 As shown, the three-finger dexterous end effector of the palm of the hand driven by three motors in series in this embodiment has three right-angle plate fingers 20, one right-angle plate finger 20 with manual eccentricity adjustment and fixing, and two fingers 20 respectively fixed in two slots. Right-angle plate fingers 20 on two bars 17 or two slotted bars 9; Two slotted bars 9 are driven by motor worm gear reducer 1 and relatively reversely rotated, based on two slotted bars 9, two The two slotted rods 17 are respectively driven by a motor planetary gear reducer 16 to rotate positively or reversely, and a motor worm gear reducer 1 and two motor planetary gear reducers 16 are cooperatively controlled; including a motor worm gear reducer 1 and a base plate 2 , threaded head drive shaft 3, two slotted one rods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com