Waste industrial cable recovery device

A recovery device and industrial technology, applied in the direction of electronic waste recovery, recycling technology, circuits, etc., can solve the problems of general cleaning effect and single operation method, and achieve the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

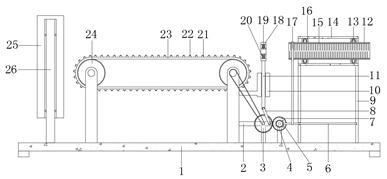

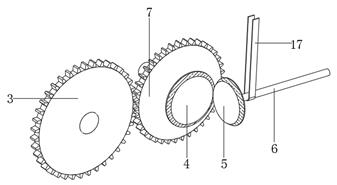

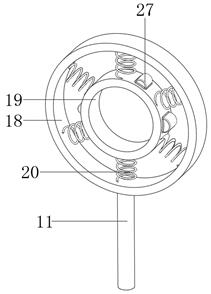

[0029] refer to Figure 1-4 , a waste industrial cable recovery device, comprising a base plate 1 with legs welded at the four corners of the bottom outer wall, a fixed rod 26 is vertically welded on both sides of one end of the top outer wall of the base plate 1, and the outer walls of the fixed rod 26 are rotated by bearings A guide roller 25 is connected, and a drag mechanism is installed on the top outer wall of the base plate 1, and the drag mechanism includes a fixed column fixedly installed on the base plate 1, and the corresponding two fixed columns are connected to the same shaft through bearing rotation, and The outer wall of the shaft rod is connected with a roller body 24 by a key, and the outer wall of the roller body 24 is sleeved with the same transmission rail belt 23, and the outer wall of the transmission rail belt 23 is bonded with rubber convex strips 21 distributed at equal distances, and the rubber convex strips There is a strip groove 22 at the central a...

Embodiment 2

[0040] refer to Figure 5 , a waste industrial cable recovery device, compared with Embodiment 1, this embodiment also includes that the inner wall of the inner ring 19 is fixedly equipped with rubber wipers 28 distributed equidistantly, and the rubber wipers 28 are far away from the end of the inner ring 19 All have triangular notches; through the rubber wiper 28 arranged on the inner ring 19, in cooperation with the triangular notches, the cable surface can be touched and rubbed during the vibration process of the cable itself.

[0041] When the present invention is used: the rubber wiper 28 arranged on the inner ring 19 cooperates with the triangular notch to touch and rub the cable surface during the vibration process of the cable itself, so as to further improve the cleaning effect of the cable surface the goal of.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com