Oil and gas pipeline axial deformation monitoring device and method

An oil and gas pipeline, axial deformation technology, applied in electromagnetic measurement devices, electric/magnetic solid deformation measurement and other directions, can solve the problems of high cost of a single branch, not the final damage position of oil and gas pipelines, etc., to achieve the effect of economical real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

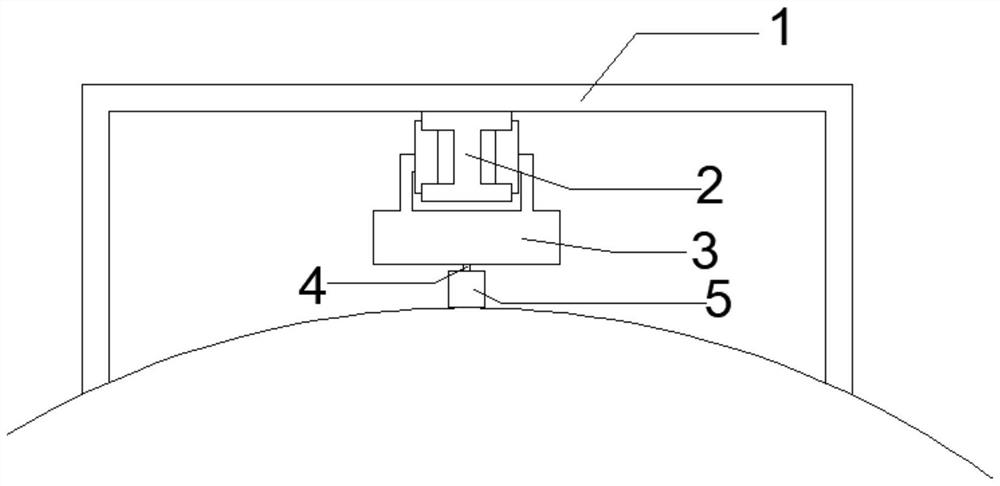

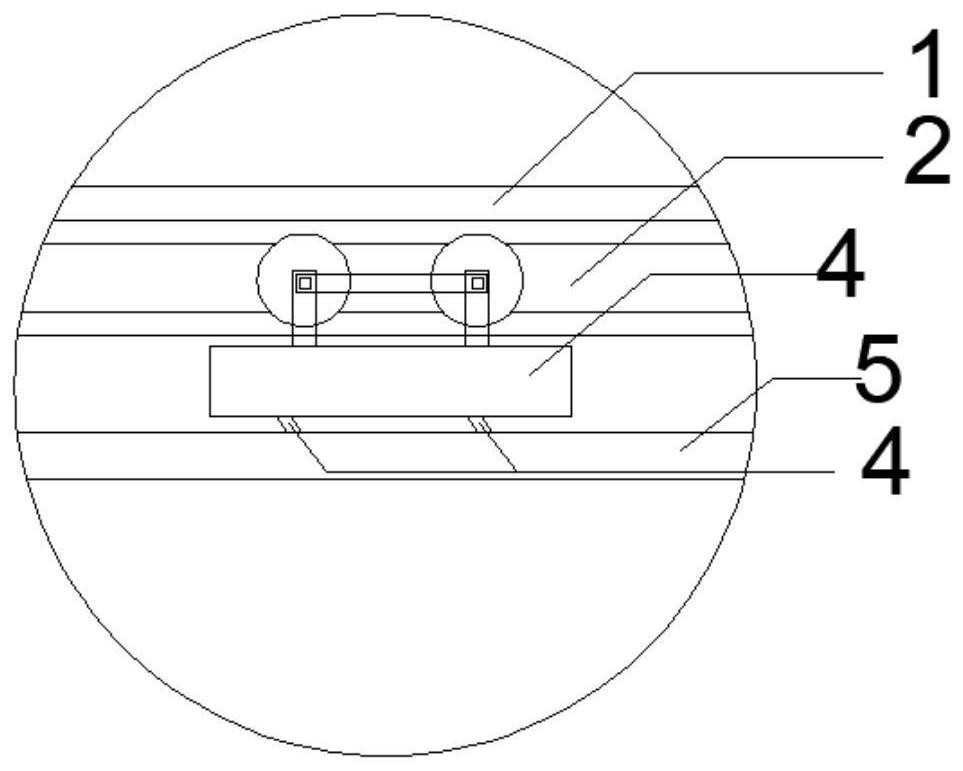

[0023] Such as figure 1 with figure 2 As shown, an oil and gas pipeline axial deformation monitoring device includes an axial and insulated ultra-long resistance wire 5 fixed on the outer surface of the oil and gas pipeline, a track 2 parallel to the ultra-long resistance wire 5 and a walking track 2 The trolley 3 and the walking trolley 3 are provided with a pair of conductive sheets 4, a current detection module, a stroke detection module, a data processing module and a data storage and uploading module, and the conductive sheet 4 is always in contact with the ultra-long resistance wire 5 on the moving path of the walking trolley 3 A loop is formed, the stroke detection module can detect the stroke of the trolley 3, the current detection module can detect the loop current, and the data processing module can obtain the deformation of the resistance wire at the stroke position according to the stroke of the trolley 3 and the loop current, that is, the stroke position can be o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com