Induction furnace

A technology of induction furnace and coil, applied in the field of induction furnace, to achieve the effect of suppressing partial discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiment of the induction furnace of this invention is demonstrated in detail based on drawing. In addition, the present invention is not limited by this embodiment.

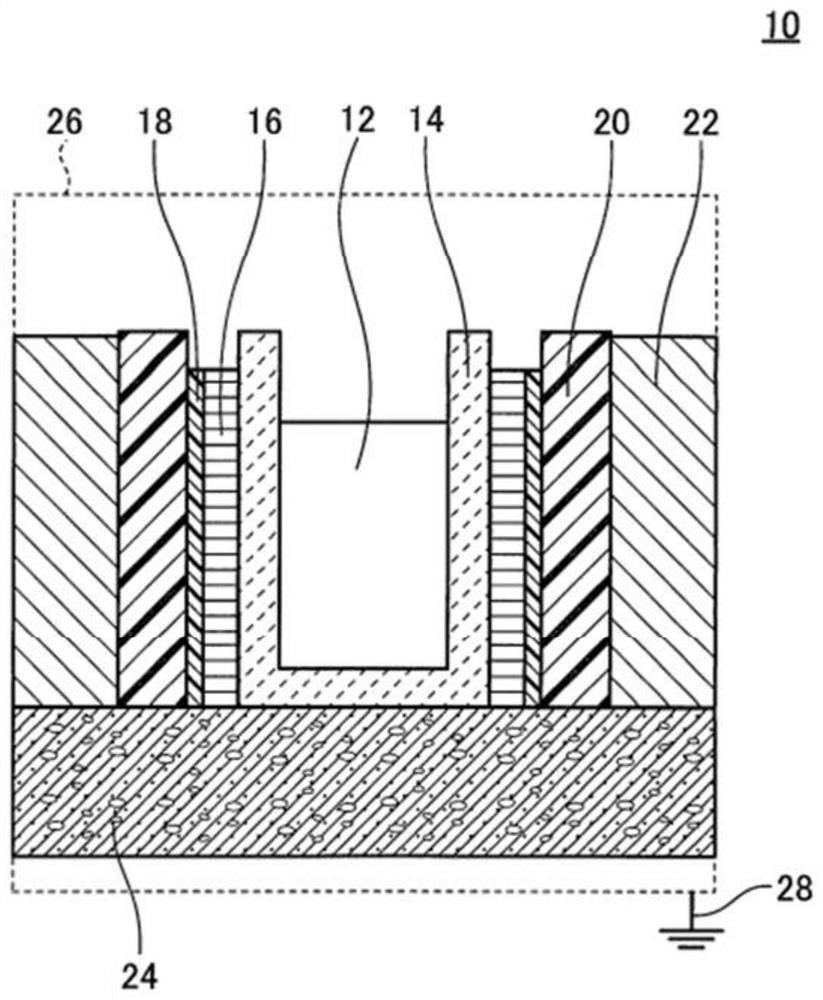

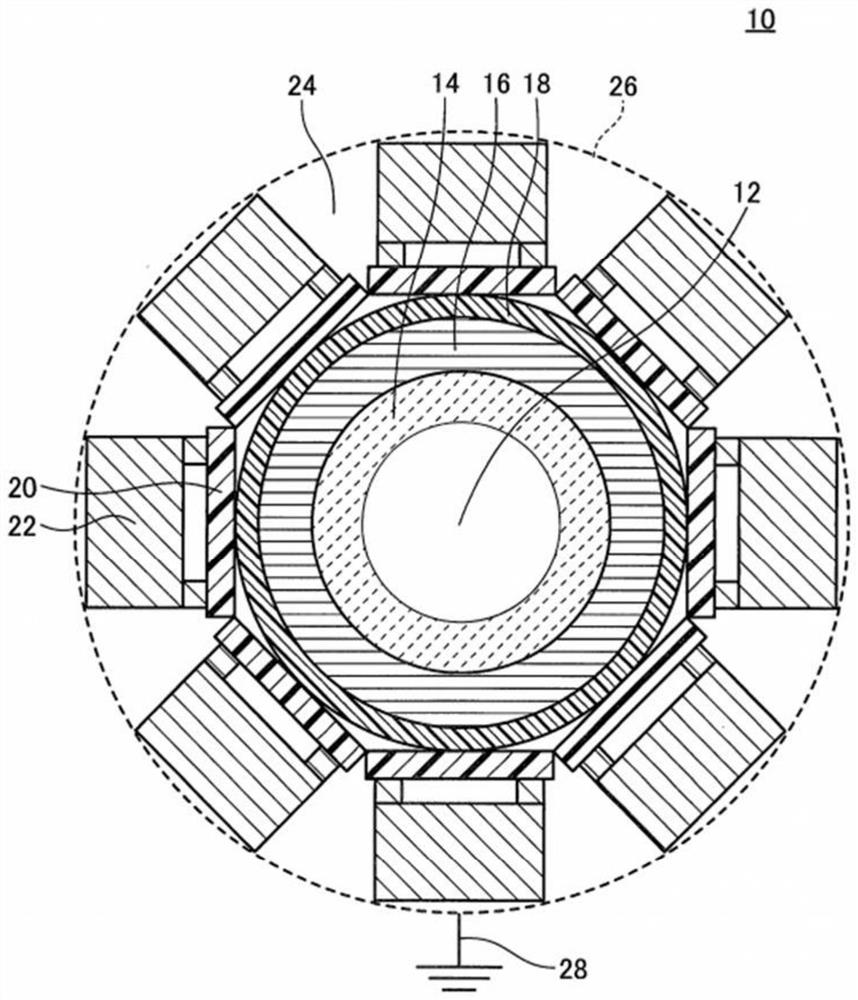

[0036] figure 1 It is a side schematic sectional view which shows the induction furnace 10 which is embodiment of this invention, figure 2 It is a schematic top view of the induction furnace 10.

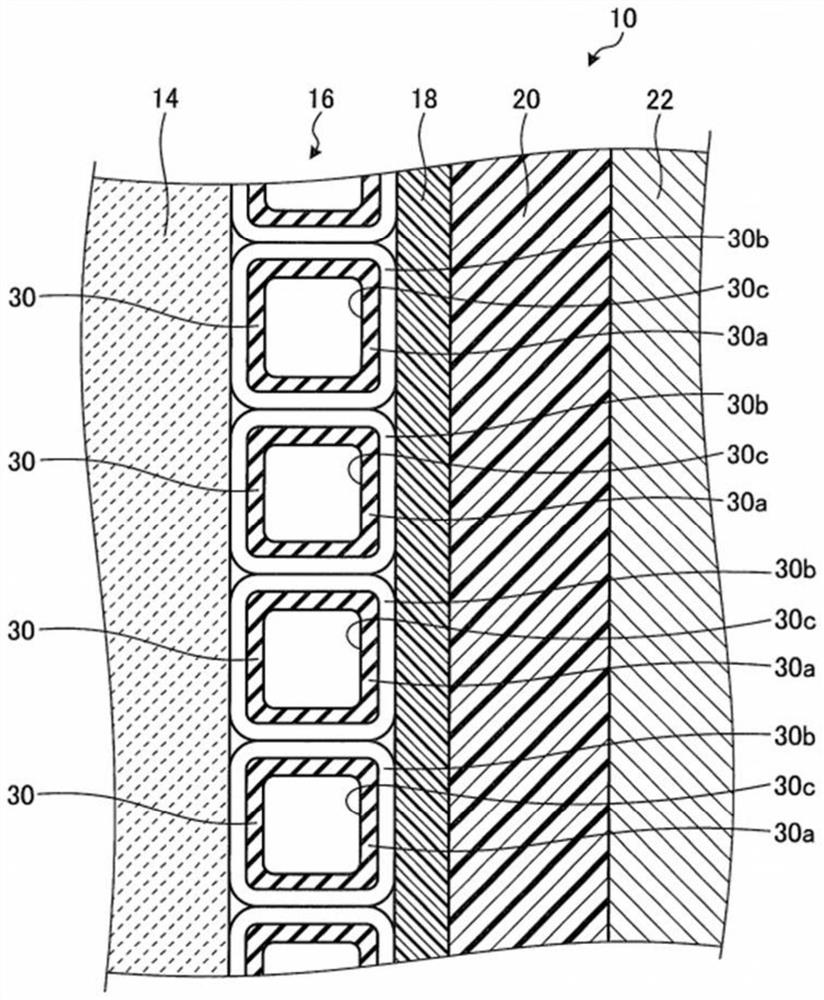

[0037] Such as figure 1 with figure 2 As shown, the induction furnace 10 includes: a crucible 14, the crucible accommodates the heated material 12; a coil 16 for induction, the coil for induction is wound around the periphery of the crucible 14; a conductive layer 18, the conductive layer The outer circumference of the coil 16 is covered; the buffer material 20 which covers the outer circumference of the conductive layer 18; Crucible 14 , coil 16 , conductive layer 18 , buffer material 20 and yoke 22 are disposed on lower castable 24 . The induction furnace 10 as a whole is covered with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com