Automatic feeding device and washing machine

A technology of automatic feeding and feeding devices, which is applied in the field of washing machines, can solve the problems of unpopularization, high cost of automatic feeding devices, damage to the laundry, etc., and achieve the effect of enriching water flow, suitable for popularization and use, and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

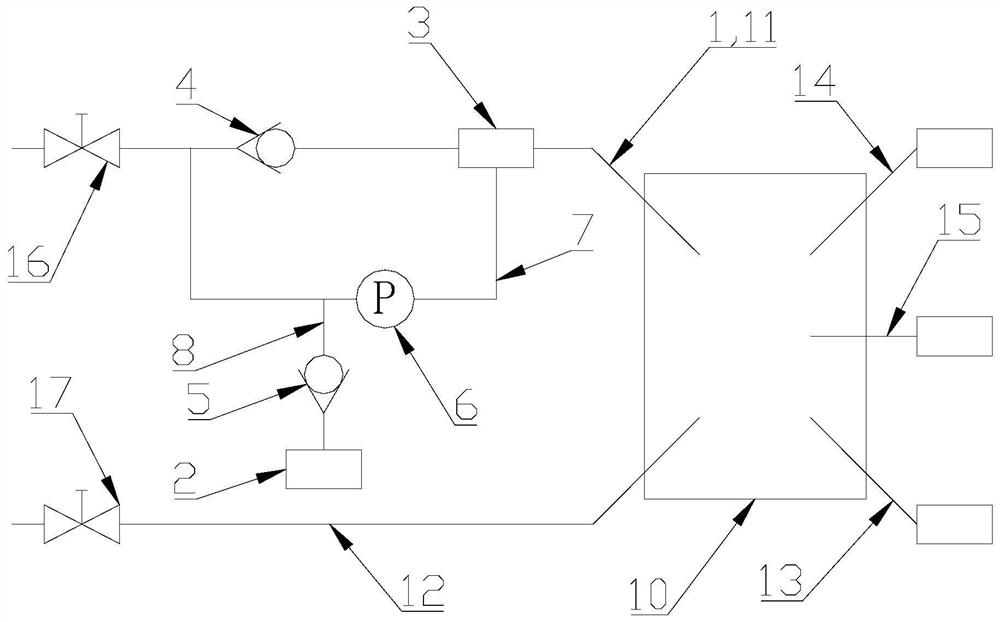

[0042] Such as figure 1 As shown, an automatic feeding device is introduced in this embodiment, which includes a water supply pipeline 1, and the water inlet end of the water supply pipeline 1 is connected with the water inlet structure of the washing machine, so as to introduce the water flow introduced into the washing machine into the feeding device; The liquid storage box 2 contains the additives used when treating the clothes; the suction structure includes a connecting pipeline at least partially connected in parallel with the water supply pipeline, and a pump providing suction power is provided on the connecting pipeline, and the liquid storage The box is connected to the connecting pipeline, and the water supply pipeline and / or the connecting pipeline are provided with a control device for controlling the flow of the liquid in the pipeline, and / or on-off, to suck the additive in the liquid storage box 2 to the water supply pipeline 1, Or feed water into the water suppl...

Embodiment 2

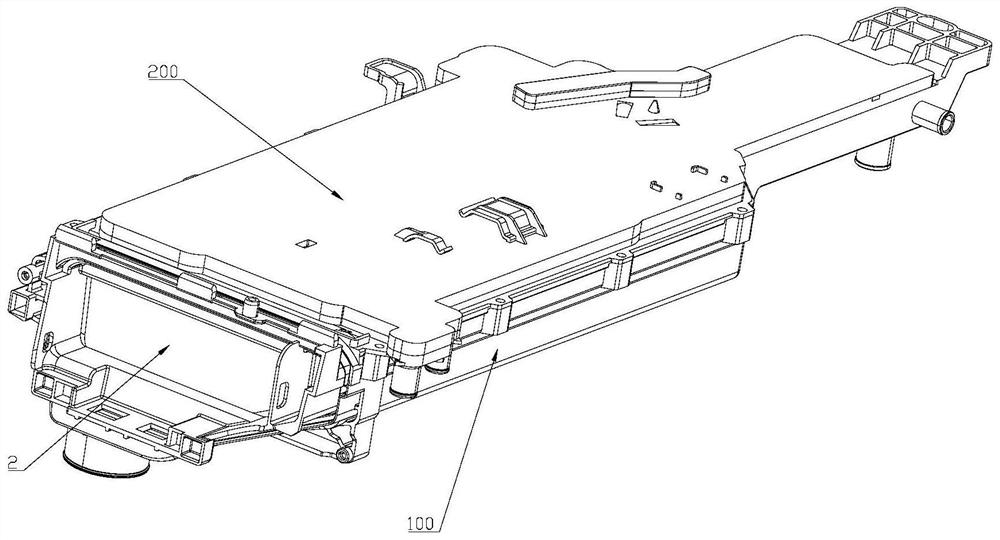

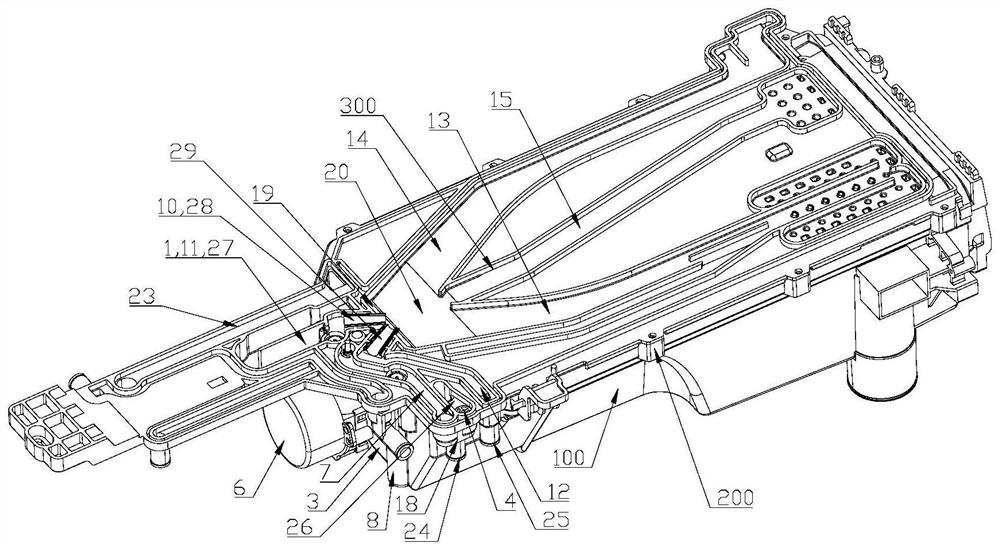

[0066] Such as Figure 2 to Figure 9 As shown, an automatic feeding device is introduced in this embodiment, which includes a water box 100; a liquid storage box 2 for containing additives is installed in the water box 100; a waterway 300 is integrated on the water box 100; preferably, the waterway The top of 300 is fastened with an upper cover 200, and the waterway 300 is integrated inside the upper cover 200 of the water box 100; further preferably, the upper cover 200 of the water box is composed of a first part and a second part that are buckled correspondingly up and down. The opposite surfaces of the first part and the second part are respectively provided with opposite openings and corresponding overlapping grooves, so that the corresponding grooves enclose the waterway 300 after the first part and the second part are fastened together.

[0067] In this embodiment, the water channel 300 of the automatic delivery device includes a water supply pipeline 1 for introducing ...

Embodiment 3

[0082] Such as Figure 2 to Figure 9 As shown, an automatic dispensing device is introduced in this embodiment, which includes a liquid storage box 2 for containing additives, a waterway 300 for water intake, and a suction structure for pumping additives in the liquid storage box 2 into the waterway 300 ; The waterway 300 is provided with a liquid storage chamber 3 connected in series, and the liquid storage chamber 3 is provided with an opening for temporarily storing the additive pumped into the waterway 300 from the opening, and the additive in the liquid storage chamber 3 and the water inlet Mixed and poured.

[0083] By setting the liquid storage chamber connected in series with the water supply pipeline on the water box, the additives pumped into the water supply pipeline are mixed with the incoming water in the water supply pipeline before being put in, realizing the pre-mixing of additives, The density of the liquid flowing to the hedging mechanism is reduced, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com