Easy-to-tear stacked heat-seal bag

A bag sealing and melting sealing technology, which is applied in the field of packaging bags, can solve the problems of low work efficiency and slow packaging operation of fusion sealing bags, and achieve the effects of saving labor costs, saving packaging time, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

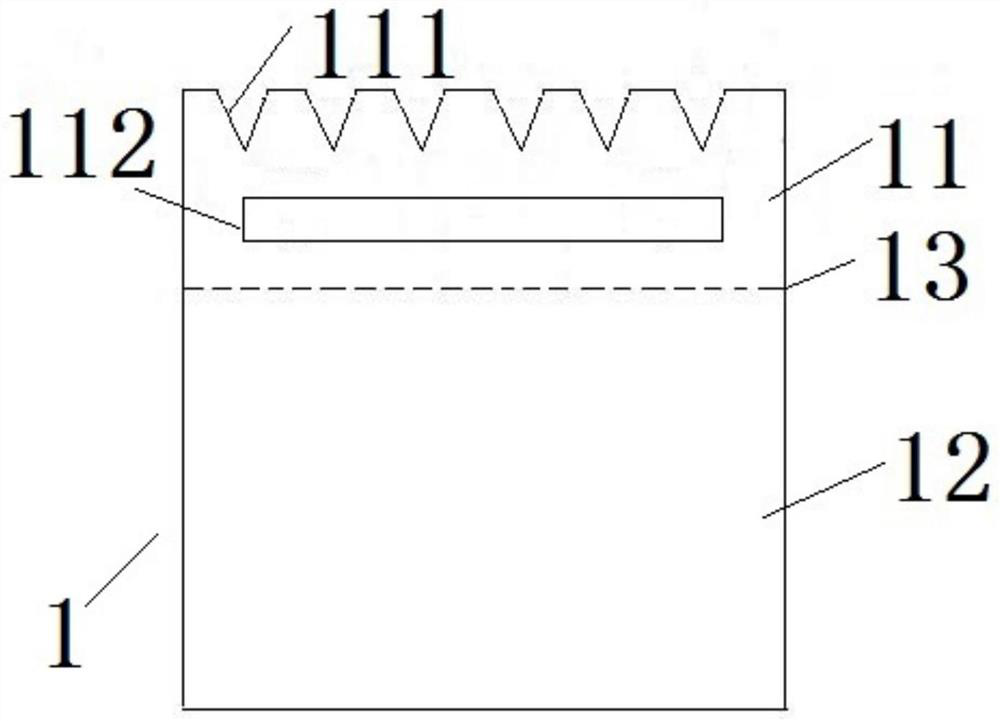

[0029] refer to figure 1 As shown, this embodiment provides an easy-to-tear stacked fusion-sealed bag, including 200 fusion-sealed bag monomers 1, the fusion-sealed bag monomer 1 includes a fixing part 11 and a fusion-sealed bag body 12, and the fusion-sealed bag body 12 and The fixing part 11 is connected, and there is a tear line 13 at the junction of the fusion bag body 12 and the fixing part 11, and the fusion bag body 12 and the fixing part 11 can be torn apart along the tear line 13; wherein, the fusion bag body 12 includes Composed of two layers of plastic film, the upper end is open, the lower end is closed and the surrounding wall is sealed in a circle to form an inner cavity, which can place light-weight simple meals, such as: small bread, sandwiches; the fusion-sealed bag body 12 is on the rear side of the opening There is a fixed part 11 extending upwards from the edge, and there is a dotted tear line 13 at the connection between the rear side of the opening and th...

Embodiment 2

[0035] refer to figure 2 As shown, the difference from Embodiment 1 is that the shape of the sealing notch 111 is semicircular, or semielliptical, with a beautiful appearance, so that multiple fixing parts are stacked and fixed to be strong and durable.

Embodiment 3

[0037] refer to image 3 As shown, the difference from Embodiment 1 is that the shape of the fixing hole 112 is square; so that when the fusion-sealed bag is fixed on the worktable, the inside of the fixing hole can be fixed by a fixing plate, which expands the scope of application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com