An equipment for spraying paint on the outer wall of a thermos cup

A technology for painting equipment and thermos cups, applied in the direction of spraying devices, etc., can solve the problems of manual painting safety, hidden dangers, labor and time consumption, etc., and achieve the effect of far away from pollution, good painting quality, and saving labor and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

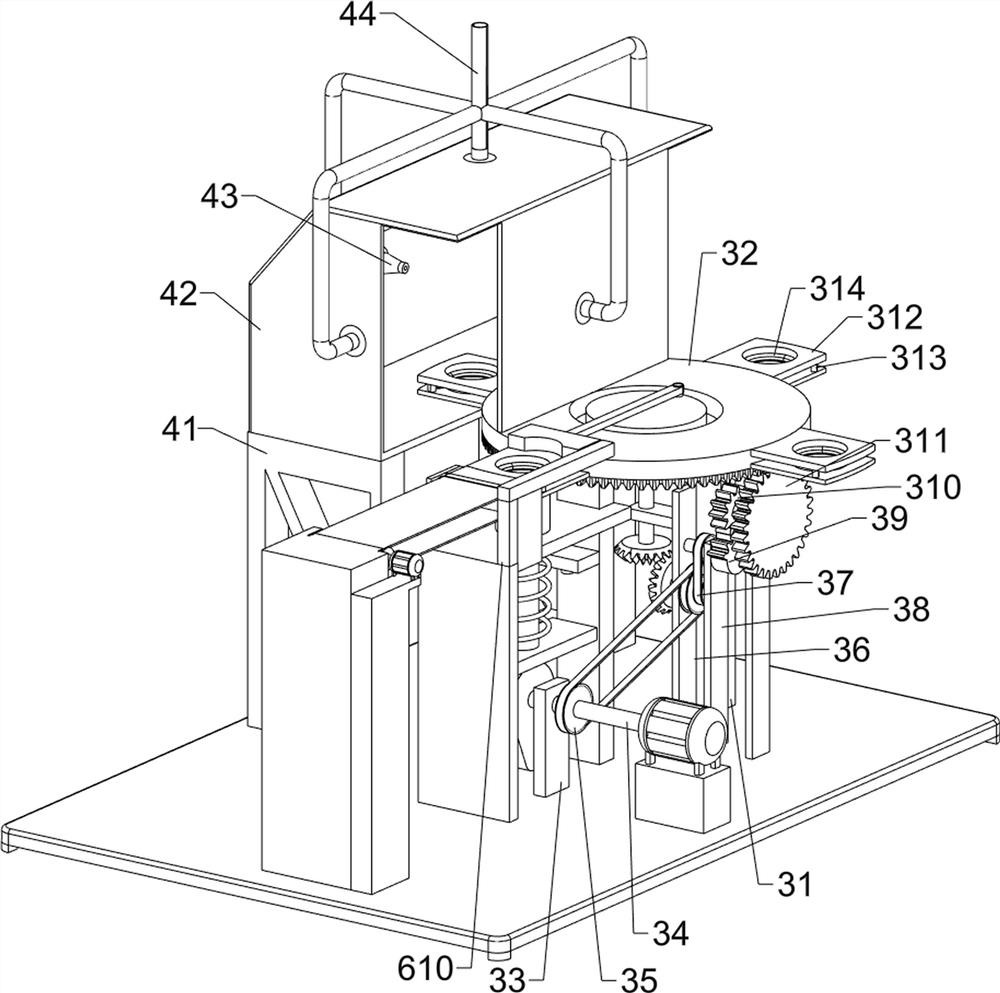

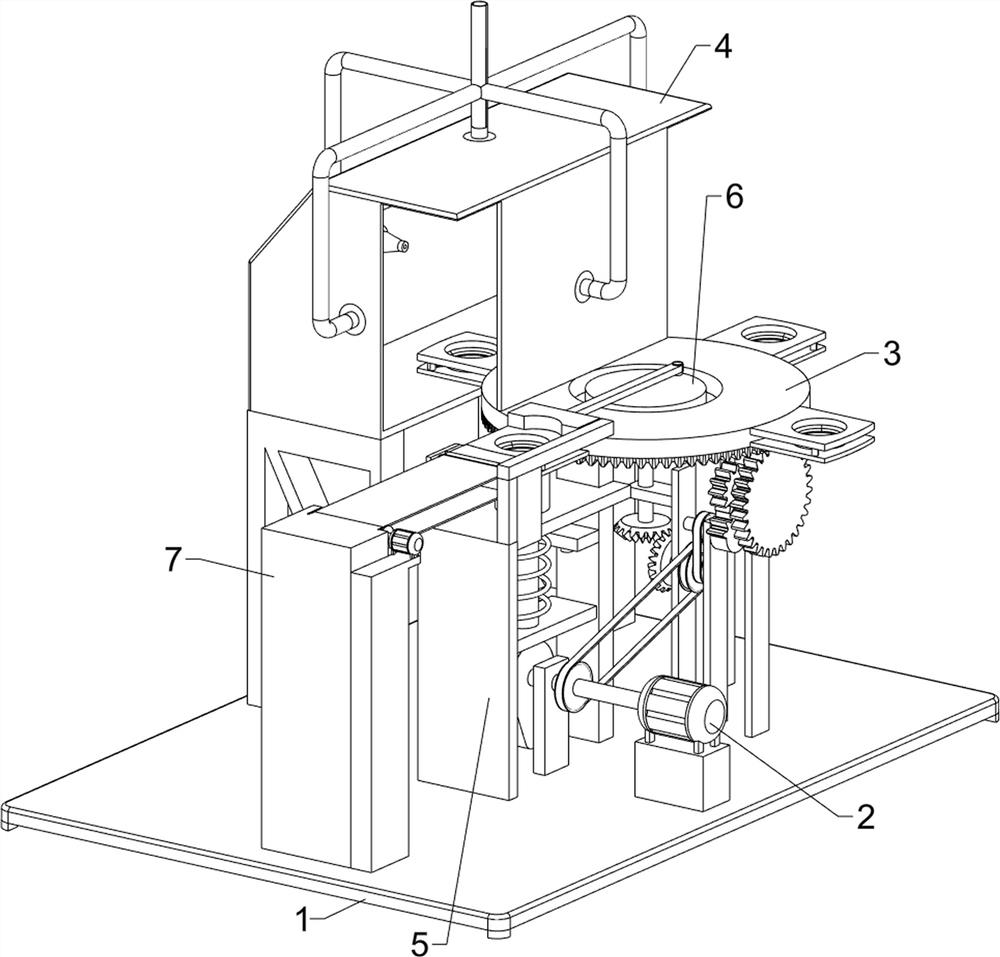

[0026] An equipment for painting the outer wall of a thermos cup, such as figure 1 , figure 2 , image 3 , Figure 4 and Image 6 As shown, it includes a base 1, a deceleration motor 2, a clamping and rotating assembly 3, a painting assembly 4 and an upward pushing assembly 5. A deceleration motor 2 is installed in the middle of the front side of the upper part of the base 1, and a clamping and rotating assembly is installed on the right side of the upper part of the base 1. 3. The upper right rear side of the base 1 is provided with a paint spraying assembly 4. The painting assembly 4 and the clamping and rotating assembly 3 cooperate with each other. The upper part of the base 1 is provided with an upward pushing assembly 5. The upward pushing assembly 5 is located on the rear side of the deceleration motor 2.

[0027] When the user needs to paint the outer wall of the thermos cup, first place the thermos cup whose outer wall needs to be painted upside down in the clampi...

Embodiment 2

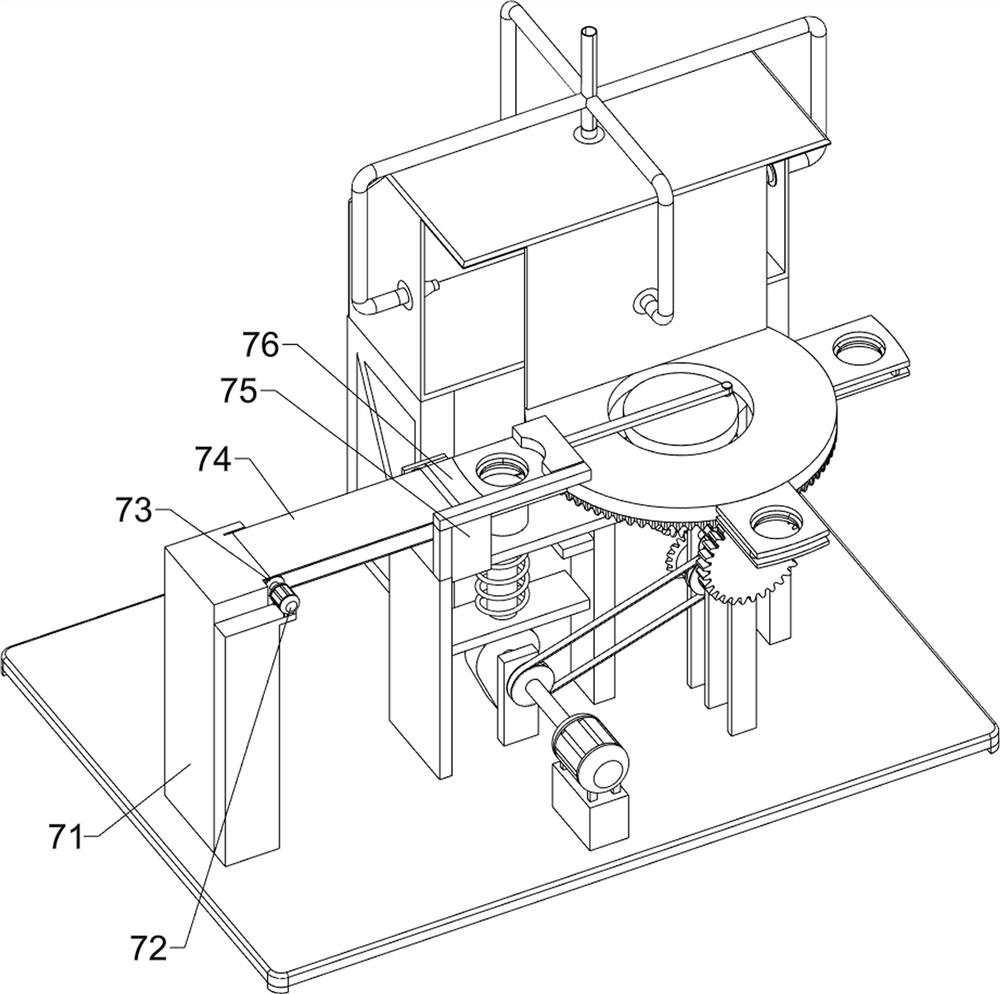

[0035] On the basis of Example 1, as figure 2 , Figure 4 , Figure 5 and Figure 7 As shown, it also includes a leftward push assembly 6, and the leftward push assembly 6 includes a first bevel gear 61, a second bevel gear 62, a third transmission shaft 63, a turntable 64, a third connecting rod 65, and a third push block 66. The sliding rail 67, the fourth connecting rod 68, the sliding block 69 and the sixth supporting plate 610, the rear side of the rotating rod is connected with the first bevel gear 61, and the upper side of the rear side of the second supporting plate 36 is rotatably connected with The third transmission shaft 63, the lower side of the third transmission shaft 63 is connected with a second bevel gear 62, the first bevel gear 61 and the second bevel gear 62 are meshed with each other, the upper side of the third transmission shaft 63 is connected with a turntable 64, and the upper part of the turntable 64 There is a third connecting rod 65 on the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com