Transformation Method of Triaxial Creep Test Result of Rock and Soil by Staged Loading to Separate Loading

A graded loading, triaxial creep technology, applied in the direction of using stable tension/pressure to test the strength of materials, analyze materials, instruments, etc., can solve the problems of many test conditions, determine the time interval, etc. Workload, the effect of reducing rigid requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0163] The transformation of the entire curve is relatively large, and the "transformation" is performed only for the deformation-time point when the stability criterion is reached for the first time under each level of loading during step-by-step loading.

[0164] The data of this embodiment is taken from the deformation curve of a creep test under graded loading of a sample numbered 14 in a series of triaxial creep tests, such as image 3 As shown, the physical indicators of the triaxial sample: silty clay, uniform gradation, sample initial size d0=61.615mm, h0=122.240mm, unsaturated soil sample, moisture content 22.38%, maximum dry density 1.55g / cm 3 , the degree of compaction is 0.95. The test condition is preset as the confining pressure 200kPa, the number of loading stages n=11, and the accumulated stepped axial pressure load value is as follows Figure 4 As shown, there is no consolidation and no drainage. During the test, the fluctuation of ambient temperature and h...

Embodiment 2

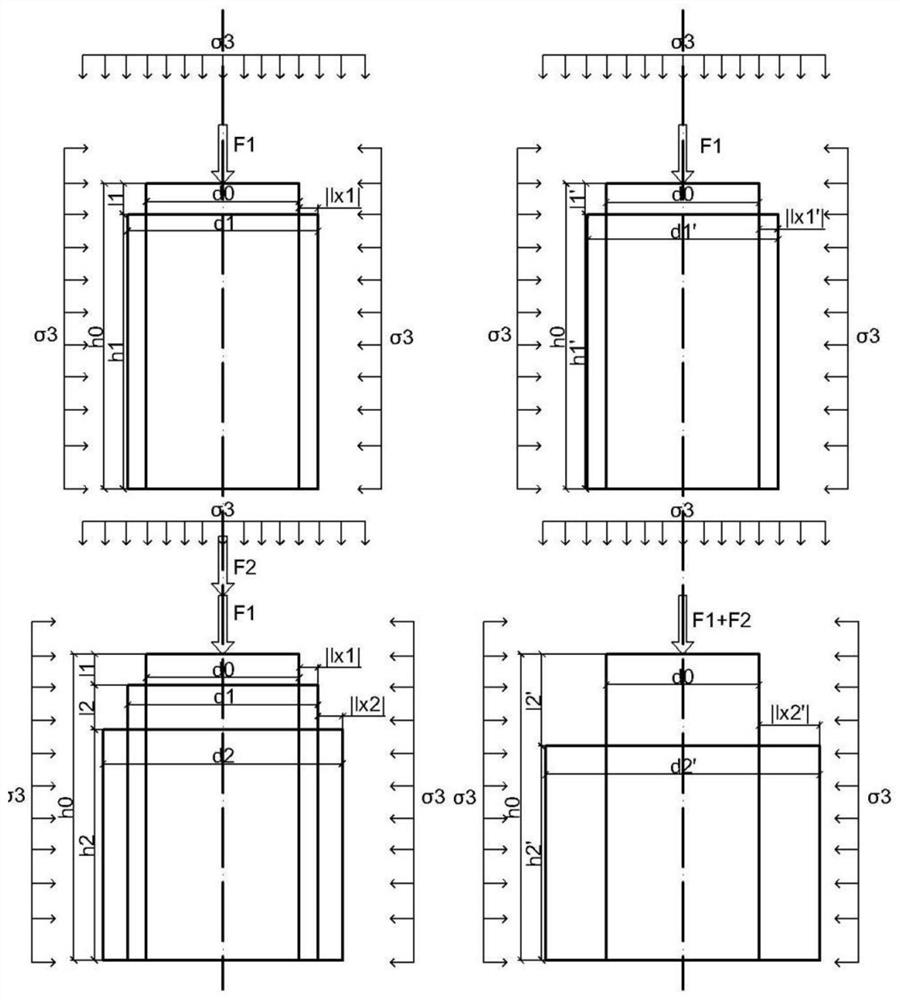

[0192] with F 1 +F 2 Take the transformation from hierarchical loading to separate loading as an example.

[0193] Extend the "equal external force work in the whole process of loading from two different ways" to "equal external force work at each moment inside the loading process". The method of applying external force work equality:

[0194]

[0195]

[0196] The calculation process can be realized by using EXCEL, and a series of a, b, c, d, e coefficients of standard one-dimensional quartic equations corresponding to different total axial loads at different loading times can be obtained, and these equations can be solved to obtain the ξ value, Choose the correct value of ξ, and then solve a series of l' i value. Figure 5 F for using EXCEL 1 +F 2 The conversion calculation results of the hierarchical loading to the separate loading. Figure 6 It is the final creep vertical deformation curve cluster of No. 14 sample transformed from staged loading to separate lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compactness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com