Aircraft with flapping wings and rotors combined

A technology of aircraft and rotor, applied in the field of aircraft, can solve the problems of limited application range, taxiing distance required for take-off runway, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The technical solution of the present invention will be described below with reference to the drawings and embodiments.

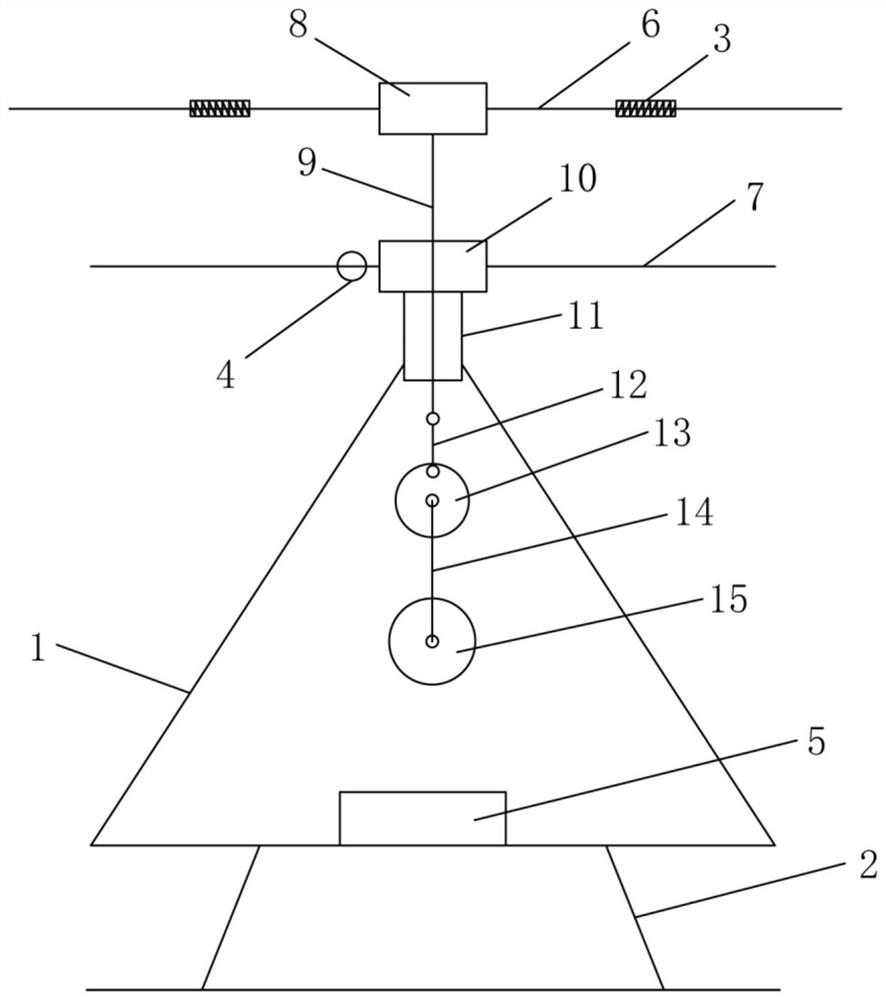

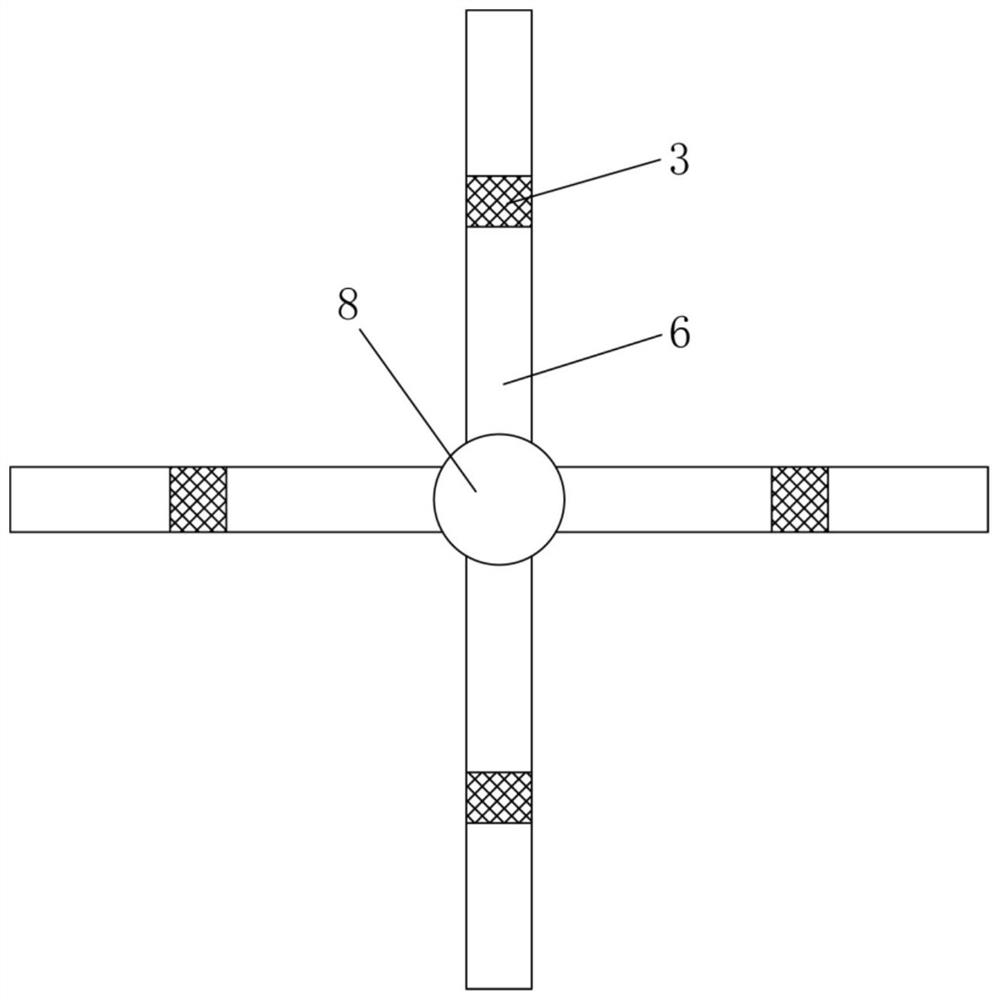

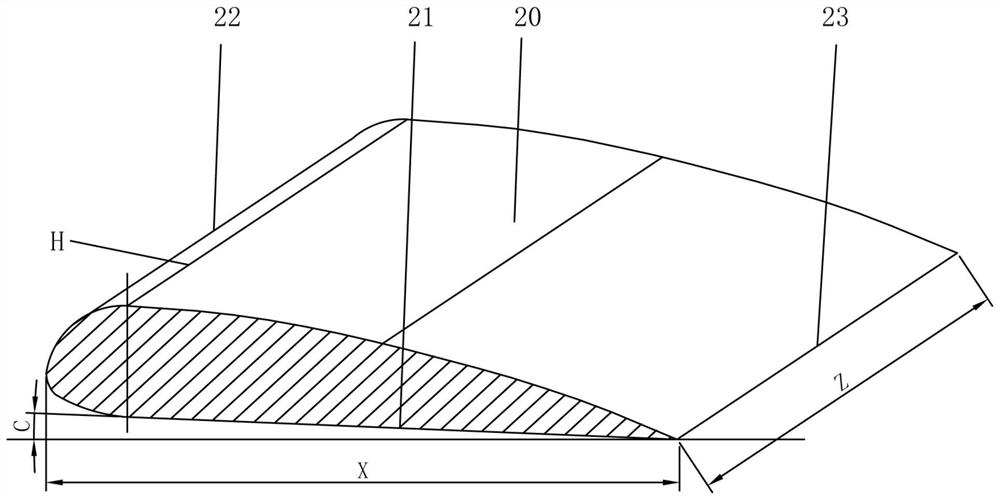

[0020]Such asfigure 1 As shown, a flapping-wing and rotor-combined aircraft according to the present invention includes a cabin 1, a driving device is provided in the cabin 1, a flying device is provided on the top of the cabin 1, and the flying device includes a first flying unit and a second flying unit, The first flying unit includes a sleeve 11, two rotating bearings 10, and rotors 7 symmetrically fixed on both sides of the two rotating bearings 10. The two rotating bearings 10 are fixed to the sleeve 11, the sleeve 11 is fixed to the nacelle 1, and the second flying unit includes Transmission rod 9, rotary bearing 8 and multiple sets of flapping wings 6 symmetrically fixed on rotary bearing 8. The rotary bearing 8 is fixed to the upper end of the transmission rod 9, and the lower end of the transmission rod 9 passes through the sleeve 11 and is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com