Special turning tool with split type tool bars for machining train spoke plate

A train wheel, split-type technology, applied to the accessories of tool holders, metal processing equipment, tool holders, etc., can solve the problem of high cost of replacing tool holders, reduce the risk of damage to turning tool accessories, reduce replacement costs, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

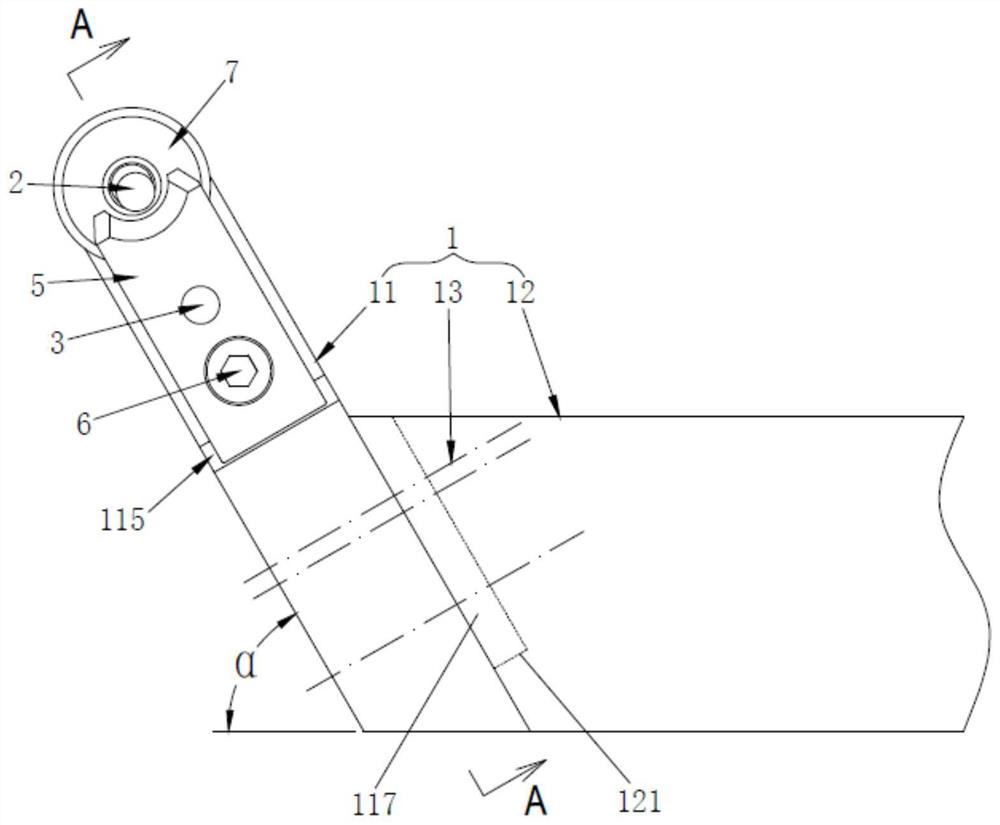

[0046] Such as figure 1 A special-purpose turning tool for train wheel panel processing with a split cutter bar shown in , includes a tool bar assembly 1 and a cutter body 7, and the tool bar assembly 1 includes a secondary tool bar 11 and a main tool bar 12 that are detachably connected together , the auxiliary cutter bar 11 is arranged at the front end of the main cutter bar 12 and extends obliquely to one side of the main cutter bar 12 , and the cutter body 7 is installed at the front end of the auxiliary cutter bar 11 . Due to the adoption of the detachable tool bar assembly 1, when the secondary tool bar 11 is damaged, only the secondary tool bar 11 can be replaced, which greatly reduces the replacement cost of accessories compared with the replacement of the entire tool bar.

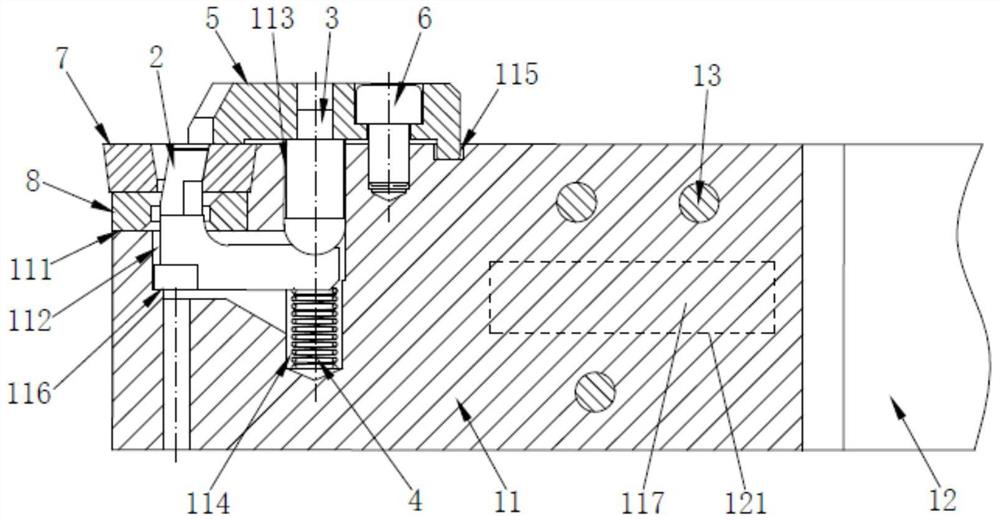

[0047] Such as figure 1 and figure 2 As shown in , in this embodiment, the auxiliary cutter bar 11 and the main cutter bar 12 are fixedly connected by several long bolts 13 . In addition, in ...

Embodiment 2

[0051]The special-purpose turning tool for train wheel panel processing in the present embodiment, the basic structure is the same as embodiment 1, and the differences and improvements are as follows: figure 2 As shown in , the special turning tool for processing train wheel webs also includes a check pin 2 , an ejector pin 3 , an elastic member 4 , a pressing block 5 and a tool shim 8 . Specifically:

[0052] The front end of the auxiliary knife rod 11 has a knife mounting groove 111 , and a cavity 112 is formed below the knife mounting groove 111 , and the cavity 112 is used to accommodate the hook pin 2 .

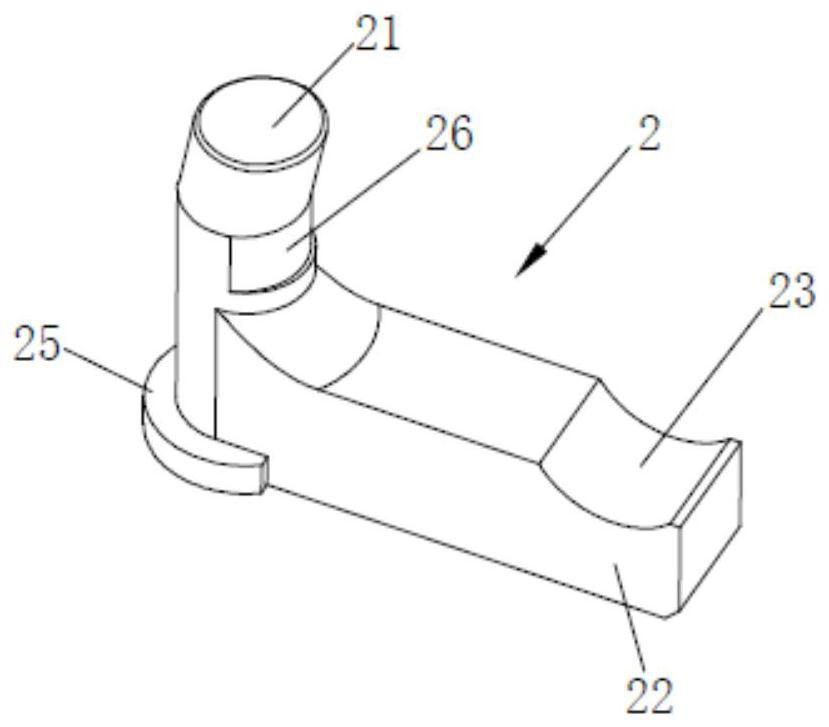

[0053] Such as image 3 As shown in , the hook pin 2 has a locking knife end 21 and a pressure end 22, the hook pin 2 is accommodated in the cavity 112, the pressure end 22 extends horizontally to the inside of the cavity 112, and the locking knife end 21 extends from the cavity 112 The upper mouth that is positioned at the middle part of knife-loading groove 111 stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com