Rapid cloth coating device for garment making

A coating device and cloth technology, which is applied to the surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of redundant structure of the coating device, difficulty in device assembly, high size requirements, etc., and achieve improvement The effect of convenient feeding, low cost and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

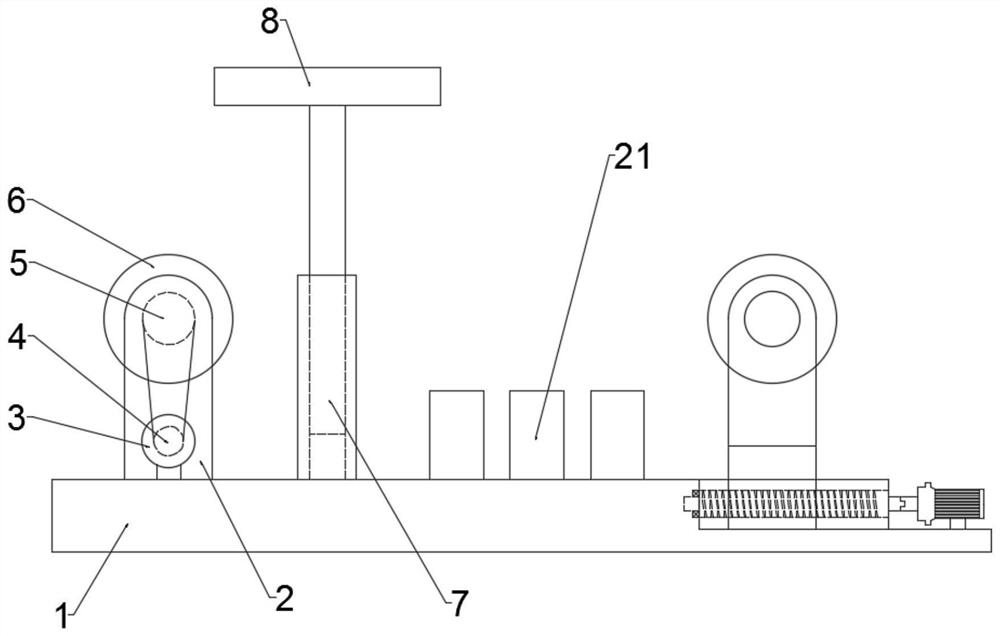

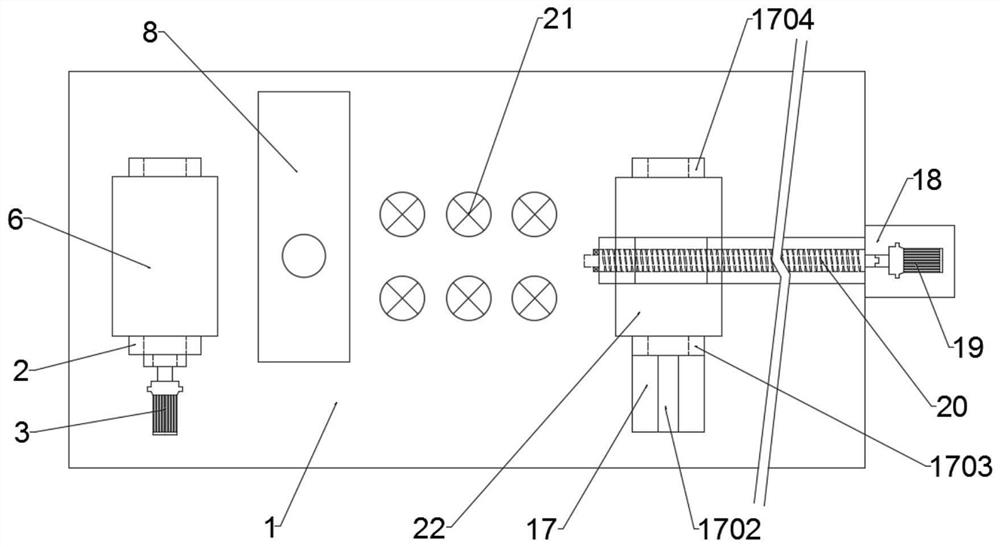

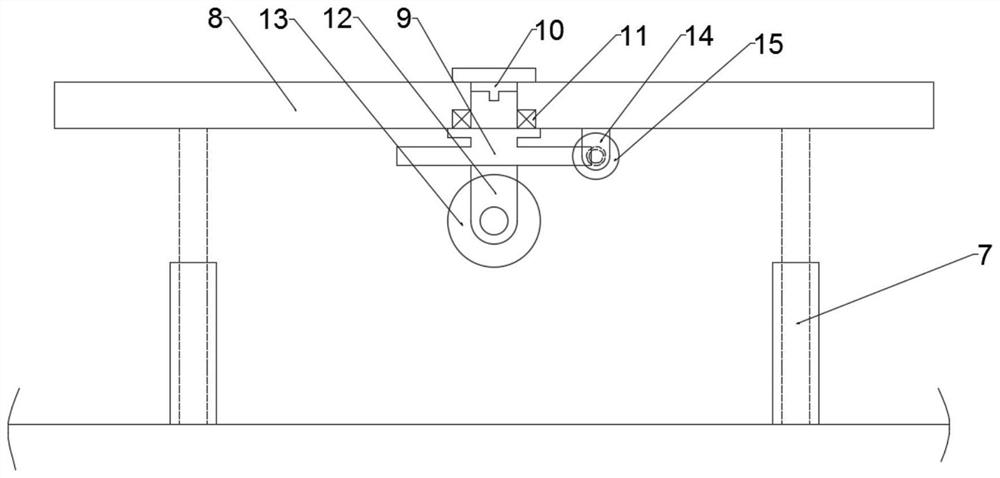

[0022] see Figure 1-5 , in an embodiment of the present invention, a cloth rapid coating device for clothing production includes a first base 1, a power device is provided on the upper left side of the first base 1, and the power device includes a first roller seat 2. There are two first roller seats 2, and one of the first roller seats 2 is detachably connected to the first base 1 for easy assembly; a first roller shaft 6 is arranged between the first roller seats 2, The first roller shaft 6 is rotationally connected with the first roller base 2, and one end of the first roller shaft 6 is provided with a first motor 3, and the output shaft of the first motor 3 is provided with a first Pulley 4, detachably connected between the first pulley 4 and the output shaft of the first motor 3, one end of the first roller shaft 6 is provided with a second pulley 5, the first pulley A belt is provided between 4 and the second pulley 5;

[0023] Further, a feeding device is provided on...

Embodiment 2

[0027] see Figure 1-2 The difference from Embodiment 1 is that in the embodiment of the present invention, a drying cylinder 21 is provided between the coating device and the feeding device.

[0028] The working principle of the embodiment of the present invention is: different from Embodiment 1, in this embodiment, a drying cylinder 21 is provided between the coating device and the feeding device, and the drying cylinder 21 can make the coating dry faster. accelerate.

[0029] The electrical components appearing in this article are all connected with the external main controller and 220V mains electricity, and the main controller can be a conventional known device that plays a control such as a computer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com