Mud scraping device for sedimentation tank of water purification plant

A technology for sedimentation tanks and water purification plants, applied in the direction of sedimentation separation, chemical instruments and methods, separation methods, etc., can solve the problems of incomplete collection of sedimentation mud, leakage of sedimentation mud, accumulation of sedimentation mud, etc., to improve dredging efficiency and avoid Accumulation, promotion of adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

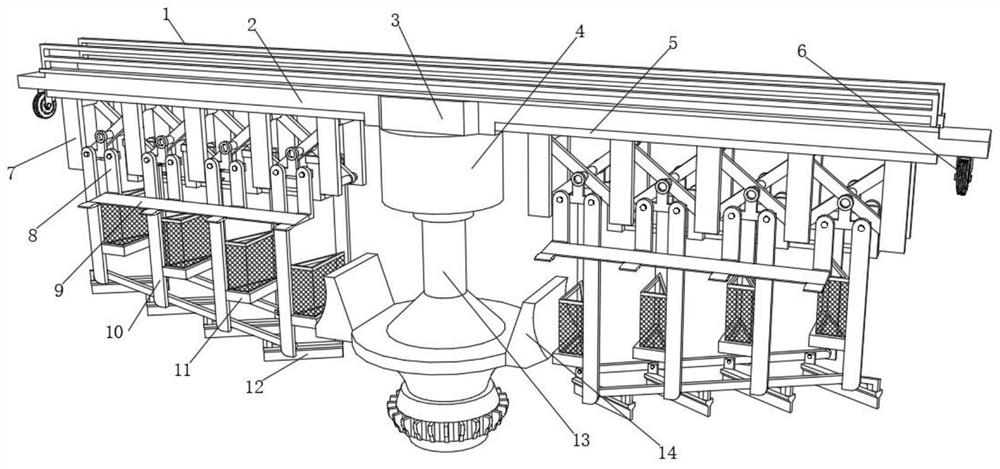

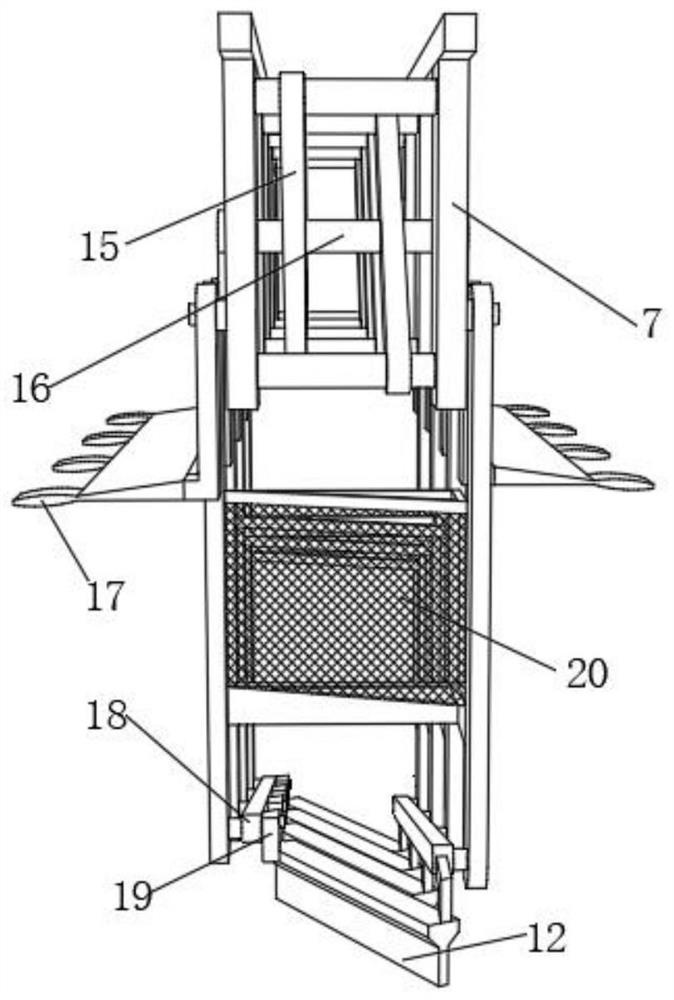

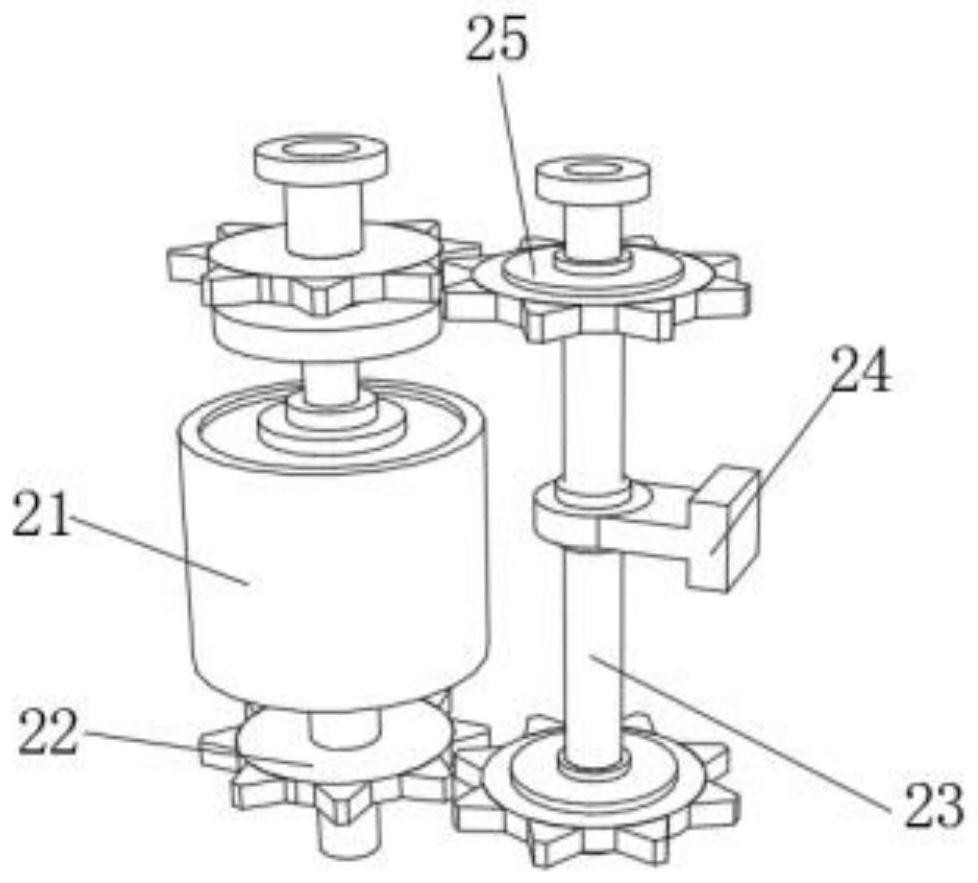

[0033] A mud scraping device used in the sedimentation tank of the water purification plant, such as Figure 1-4As shown, it includes a railing 1, the bottom middle outer wall of the railing 1 is fixed with a fixed plate 3 by bolts, and the outer walls on both sides of the fixed plate 3 are respectively fixed with two mud-scraping bridges 2 by bolts, and the bottom of the two mud-scraping bridges 2 The outer walls on both sides are respectively fixed with two limit plates 5 by bolts, and the middle outer walls at the bottom of the two mud scraping bridges 2 are respectively fixed with the same machine base 4 by bolts. A mud guiding mechanism is provided, and a mud scraping mechanism is arranged under the two mud scraping bridges 2, and each mud scraping mechanism includes two sets of mounting plates 7 equidistantly distributed, more than three reinforcing ribs 15 and connecting shafts 16, two A set of the first connecting plate 8 and the second connecting plate 10, two scum gu...

Embodiment 2

[0039] A mud scraping device used in the sedimentation tank of the water purification plant, such as Figure 1-2 As shown, in order to solve the problem of scum adsorption and filtration; this embodiment makes the following improvements on the basis of embodiment 1: the outer walls of the opposite sides of every two second connecting plates 10 are fixed with triangular mounting seats 11 by bolts, and each triangular The top outer wall of the mounting seat 11 is fixed with an adsorption net 20 by bolts; when the second connecting plate 10 rotates, it can effectively drive the rotation of the adsorption net 20 at the top of the triangular mounting seat 11, thereby effectively promoting the scum inside the sedimentation tank. Adsorption promotes the efficiency of subsequent cleaning of scum, and also has a certain purification effect on water sources.

[0040] Wherein, one side outer wall of each described scum guide plate 9 is all welded with arc-shaped floating sheets 17 distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com