Convenient-to-adjust climbing frame for construction industry

An industry and construction technology, applied in the field of climbing frames that are easy to adjust, can solve problems such as hammers, wrench workpieces falling, operator injuries, single-layer climbing frames height is not suitable, etc., to avoid collisions, easy to operate, and improve construction safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

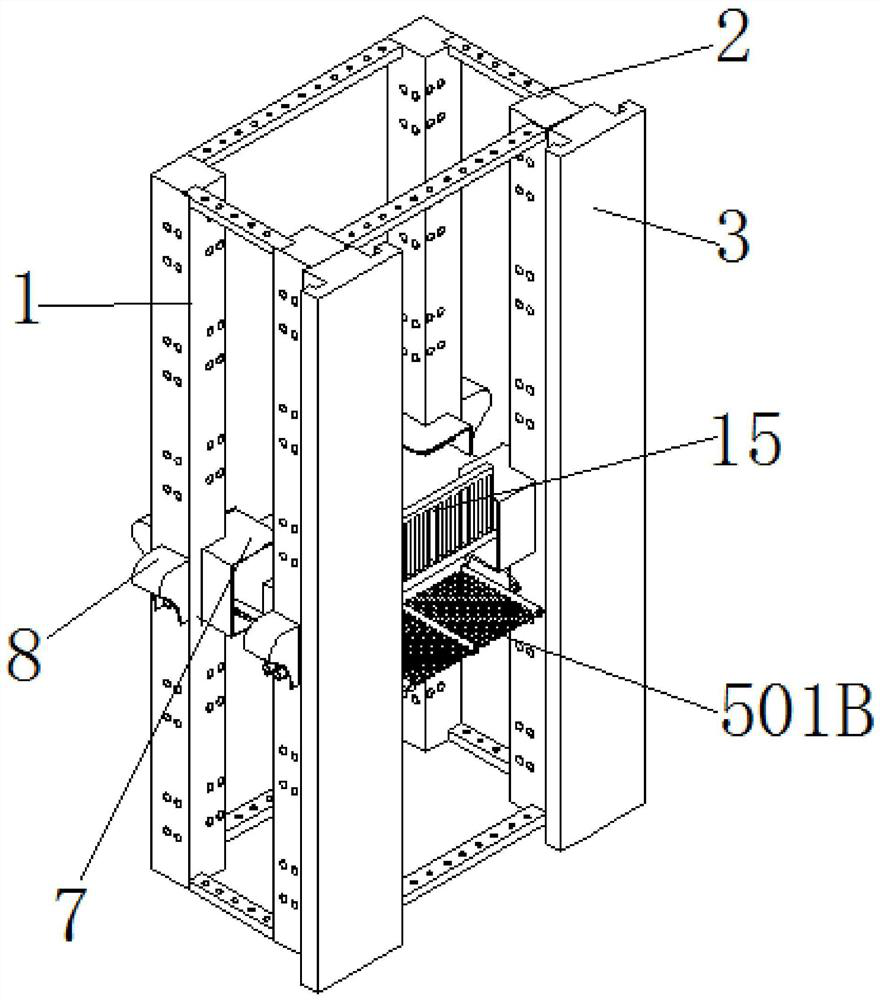

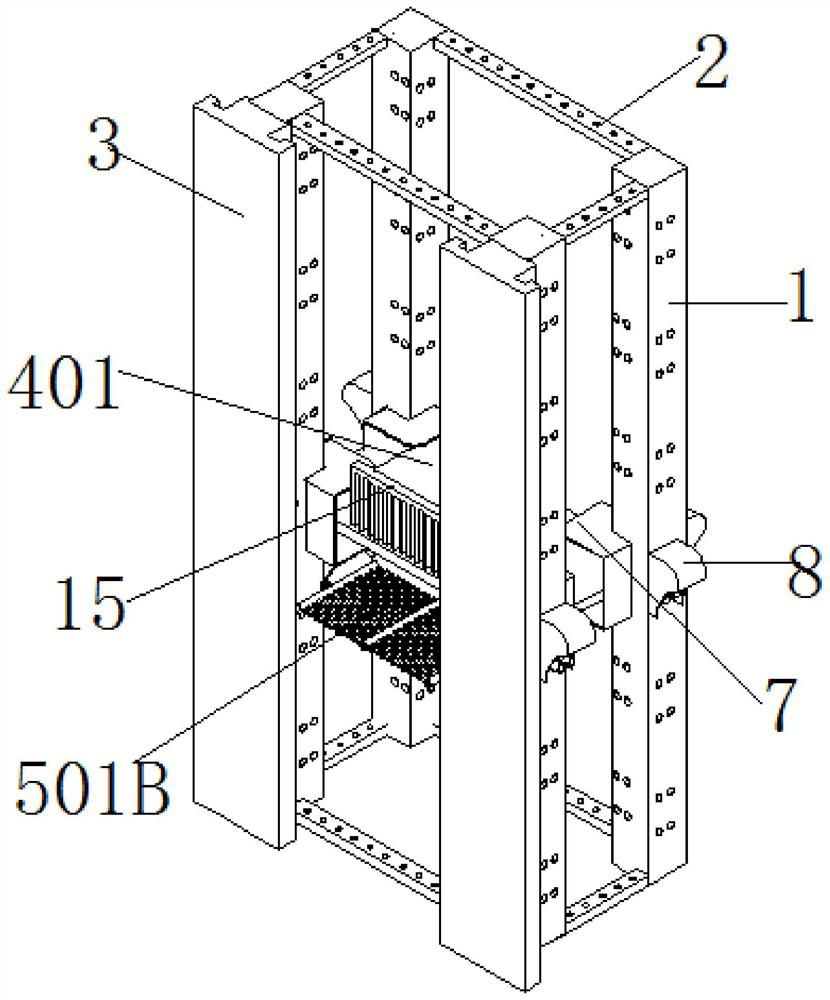

[0036] Embodiment 1 has introduced a kind of climbing frame that is easy to adjust in construction industry, as Figure 1-3 As shown, it includes a vertical beam 1, a cross beam 2, a guide rail 3, a movable pedal assembly 4 and a falling object receiving assembly 5;

[0037] There are four vertical beams 1, eight cross beams 2, and two guide rails 3. The tops of the four vertical beams 1 are fixedly connected with four cross beams 2; the bottom ends of the four vertical beams 1 are also fixedly connected with four cross beams 2; The four beams 2 at the top are vertically connected end to end and the upper surfaces of the four beams 2 are flush with the upper surface of the vertical beam 1; the four beams 2 at the bottom of the vertical beam 1 are vertically connected end to end and the lower surfaces of the four beams 2 are aligned with the vertical The lower surface of 1 is flush; the crossbeam 2 is equidistantly provided with bolt through holes 1 vertically penetrating the cro...

Embodiment 2

[0043] Embodiment 2 is an improvement on the basis of Embodiment 1, as Figure 7-9 As shown, wherein, the top and the bottom of each L-shaped connecting plate 402 are fixedly connected with a pair of rain shields 7, and the side of the rain shield 7 close to the vertical beam 1 is in close contact with the vertical beam 1; the vertical beam 1 and the nut The fixedly connected area is also fixedly connected with a rain shield 8, the rain shield 8 is located between the vertical beam 1 and the nut and the side of the rain shield 8 close to the vertical beam 1 is in close contact with the vertical beam 1; Spacers 9 are also arranged between them; a rain shield 8 is fixedly connected to the vertical beam 1 of the guide rail 3, and a pair of rain shield 8 is fixedly connected to the vertical beam 1 away from the guide rail 3.

[0044] In this embodiment, by setting the rain shield 7, the connection between the bolt and the L-shaped connecting plate 402 can be avoided from being was...

Embodiment 3

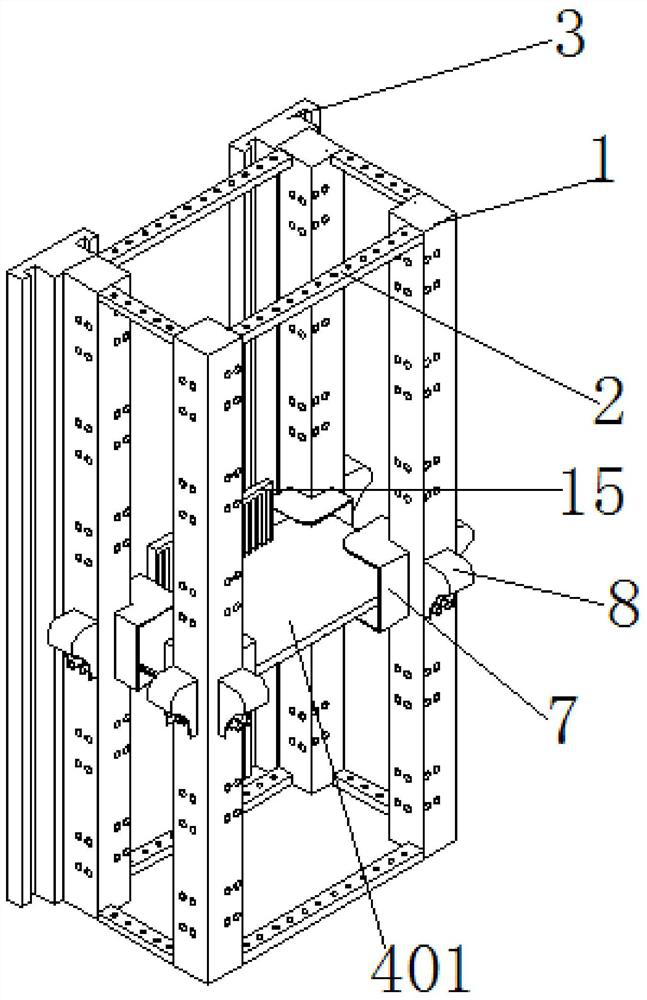

[0046] Embodiment 3 is an improvement on the basis of Embodiment 1, as Figure 10 as shown in Figure 10 As shown, the upper surface of the footboard 401 is fixedly connected with a guardrail 15 on a side close to the receiving mesh plate 501 .

[0047] In this embodiment, by providing the guardrail 15 on the footboard 401 , it is possible to prevent workers from stepping on the receiving net plate 501 , thereby improving the operational safety of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com