Speed changing device

A speed change device and turntable technology, which is applied in the field of speed change transmission, can solve the problems of large size of the speed change device, affect the service life, and be prone to failure, etc., and achieve the effects of large change range, extended life, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

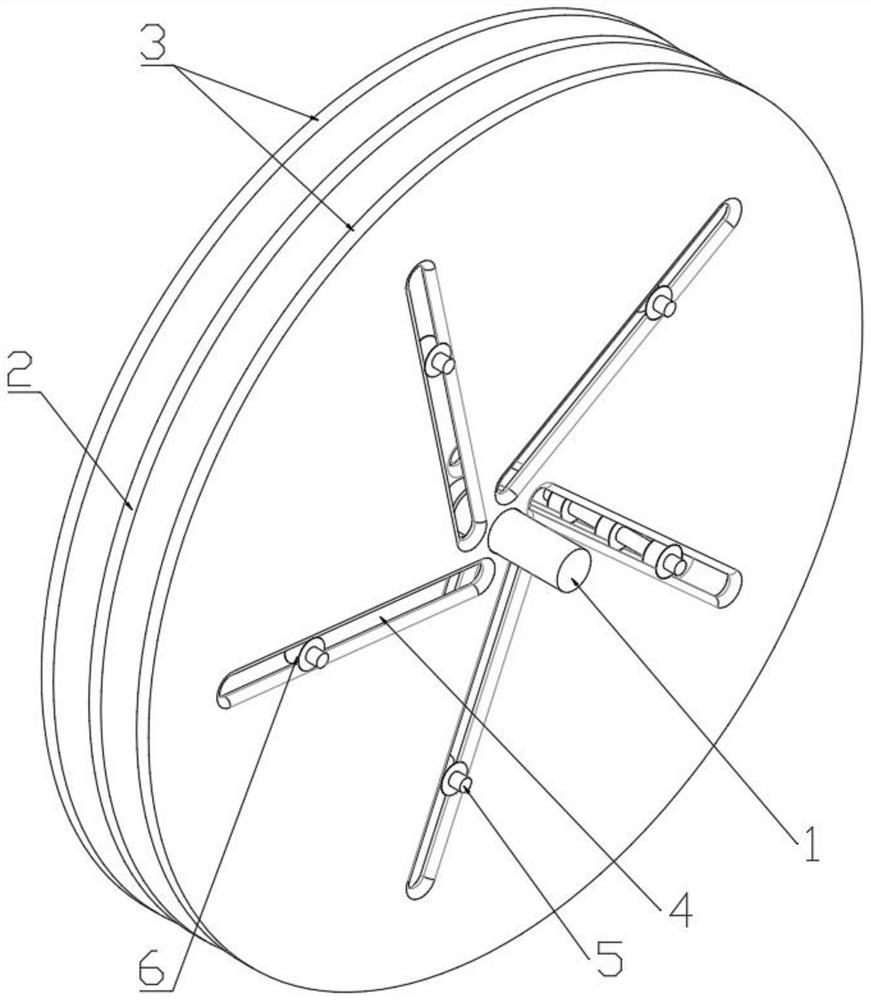

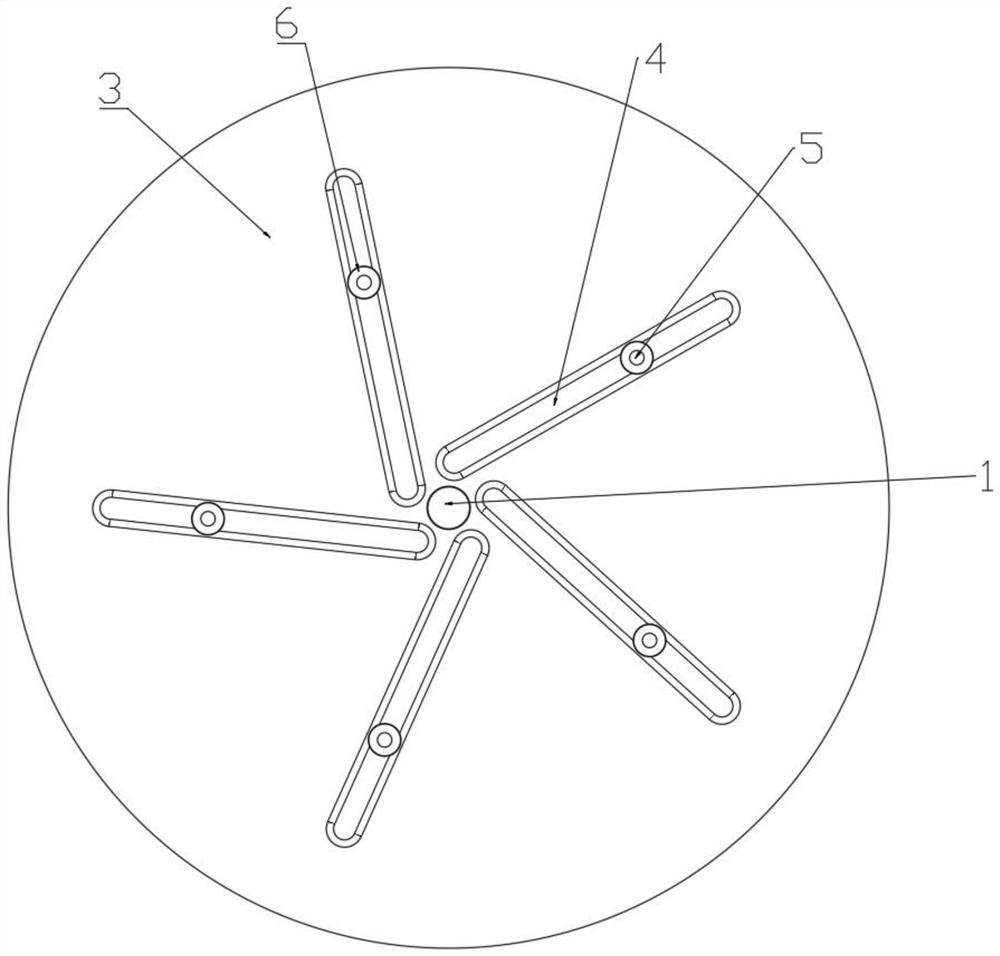

[0014] Embodiment 1, in conjunction with attached Figure 1-3 , a speed change device, comprising a rotating main shaft 1, a fixed turntable 2 fixedly connected to the rotating main shaft 1, a driven turntable 3 symmetrically arranged on both sides of the fixed turntable 2, and the driven turntable 3 is rotatably connected to the rotating main shaft 1; The fixed turntable 2 and the driven turntable 3 are provided with strip chutes 4 that cooperate with each other. A plurality of bar-shaped chutes 4 on the driven turntable 3 are evenly distributed along the circumference, and a plurality of bar-shaped chutes 4 are evenly distributed along the circumference; the bar-shaped chute 4 is provided with a slide bar 5, and the The direction of extension of the slide bar 5 is perpendicular to the surface where the fixed turntable 2 is located. The slide bar 5 is rotatably connected with a roller 6 cooperating with the strip chute 4 . The roller 6 can only slide and roll relative to the ...

Embodiment 2

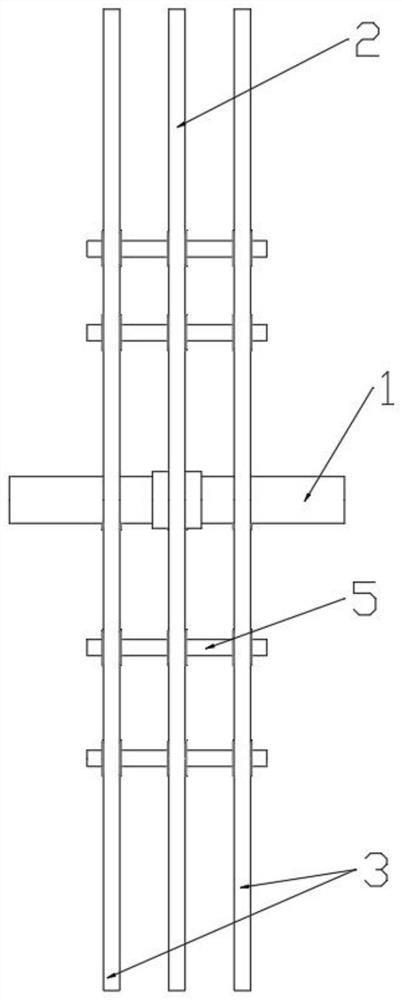

[0017] Embodiment 2, in conjunction with attached Figure 4 , comprising a rotating main shaft 1, a fixed turntable 2 fixedly connected to the rotating main shaft 1, a driven turntable 3 symmetrically arranged on both sides of the fixed turntable 2, and the driven turntable 3 is rotationally connected with the rotating main shaft 1; the fixed turntable 2 1. The driven turntable 3 is provided with bar chutes 4 that cooperate with each other, and the number of bar chutes 4 on the fixed turntable 2 and the driven turntable 3 is provided with a plurality, and the plurality of bar chutes on the fixed turntable 2 Shaped chute 4 is evenly distributed along the circumference, and a plurality of bar-shaped chutes 4 on the driven turntable 3 are evenly distributed along the circumference; the bar-shaped chute 4 is provided with a slide bar 5, and the extension direction of the slide bar 5 Vertical to the surface where the fixed turntable 2 is located, the slide bar 5 is rotatably connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com